Removable wound stator for integrated motor/compressor

A stator and motor technology, applied in the field of supercharged gas cooling motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

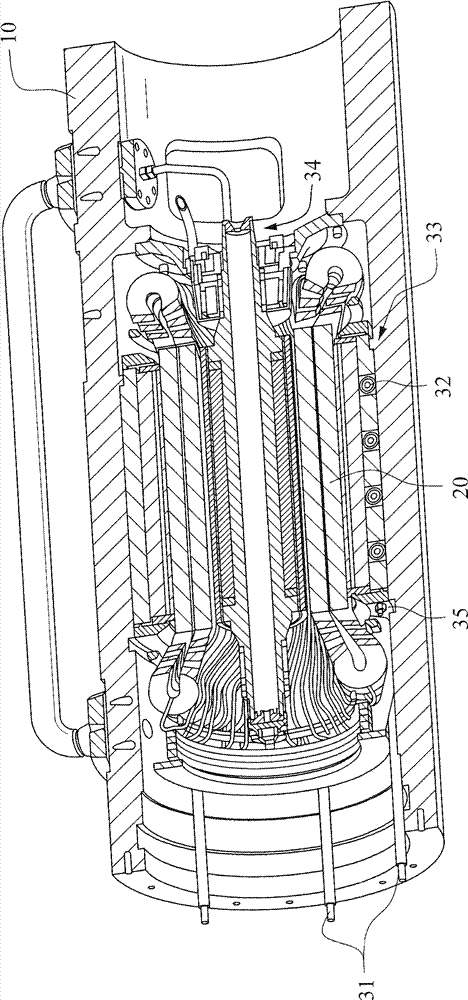

[0044] figure 1 An exemplary embodiment of a charge gas cooled integrated motor-compressor unit is depicted. exist figure 1 , the pressure vessel is shown at 10 to include therein the stator core 20 (in figure 2 shown in ). Pressure vessel 10 includes inlets, outlets, liners, plates and connections for necessary inputs and connections include: stator leads 11; stator gauges 12; gas inlet 13; gas outlet 14; and access plate 15 (cover plate not shown out).

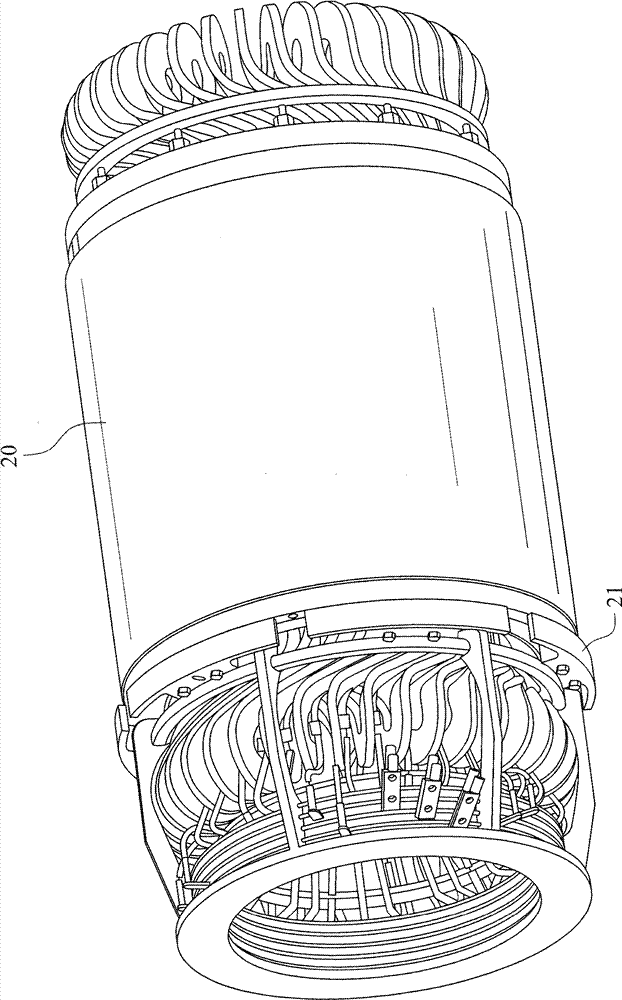

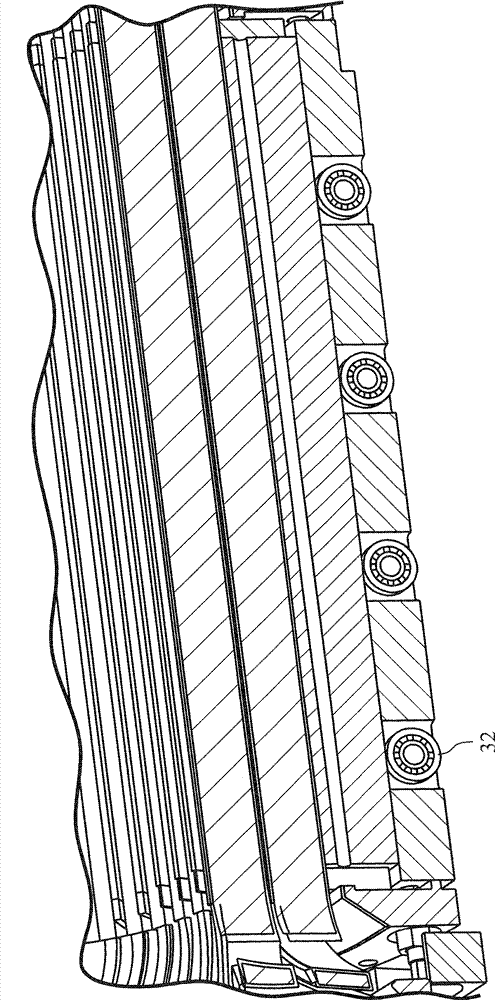

[0045] figure 2 A wound stator core 20 fitted with an axial holding device 21 is shown. As will be described in more detail below, the axial retention means 21 maintains the axial position of the stator core within the pressure vessel during transport and during operating conditions. image 3 The assembly of the stator core 20 within the pressure vessel 10 is shown. Positioning of the stator core 20 within the pressure vessel 10 is facilitated by means of the tool 31 via the rollers 32 . A shoulder 33 is formed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com