HIGH STRENGTH, HIGH STRESS CORROSION CRACKING RESISTANT AND CASTABLE Al-Zn-Mg-Cu-Zr ALLOY FOR SHAPE CAST PRODUCTS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

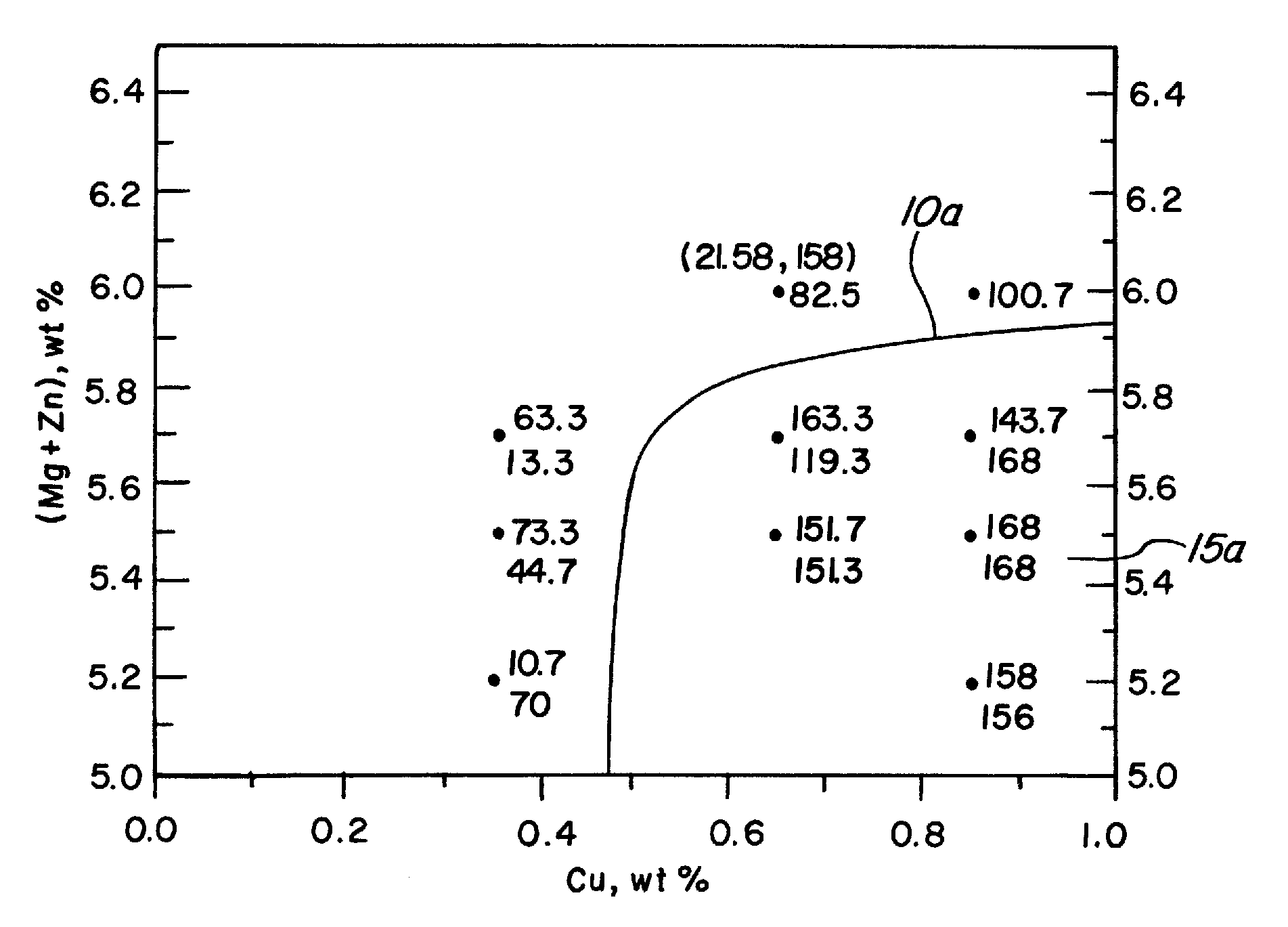

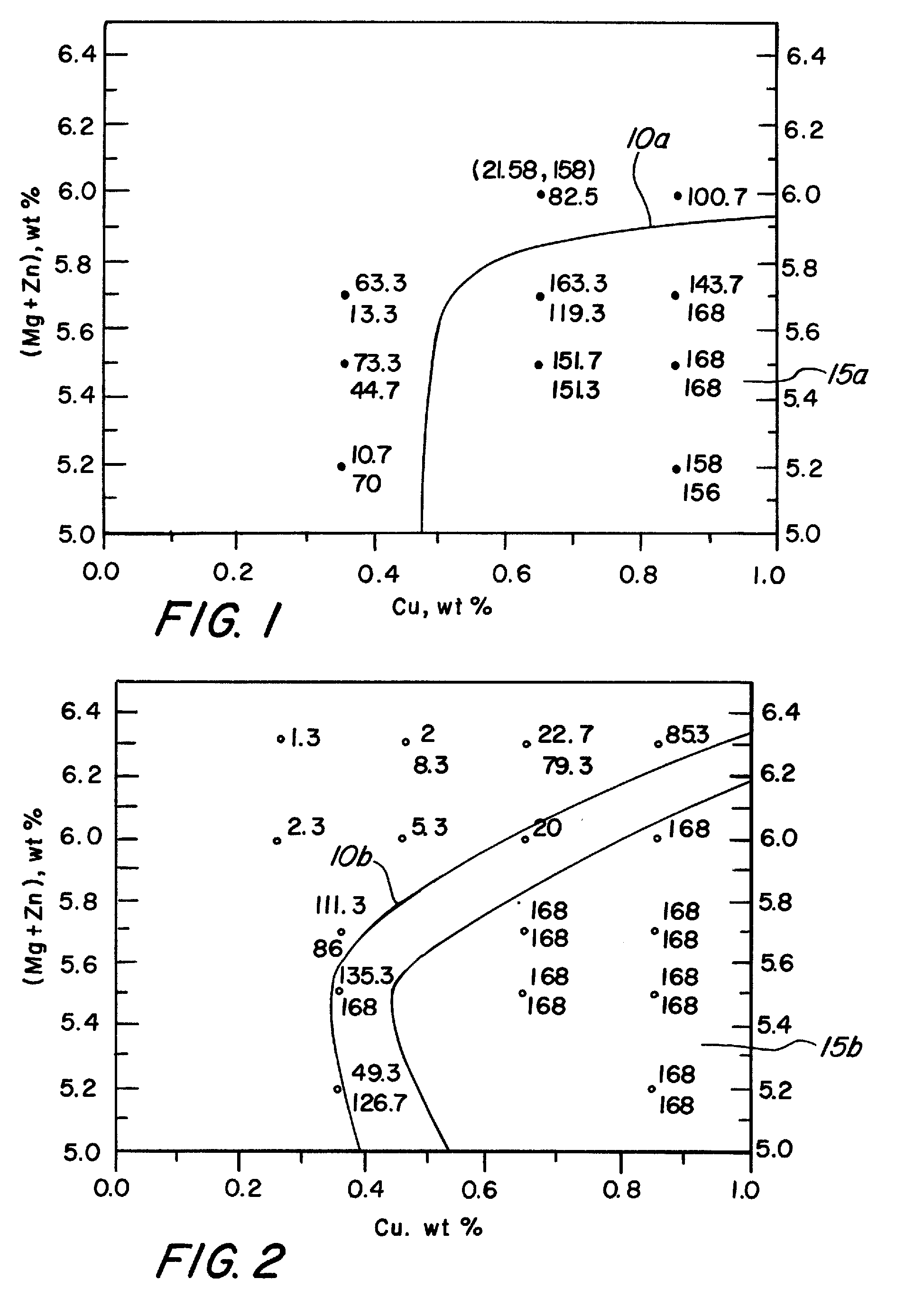

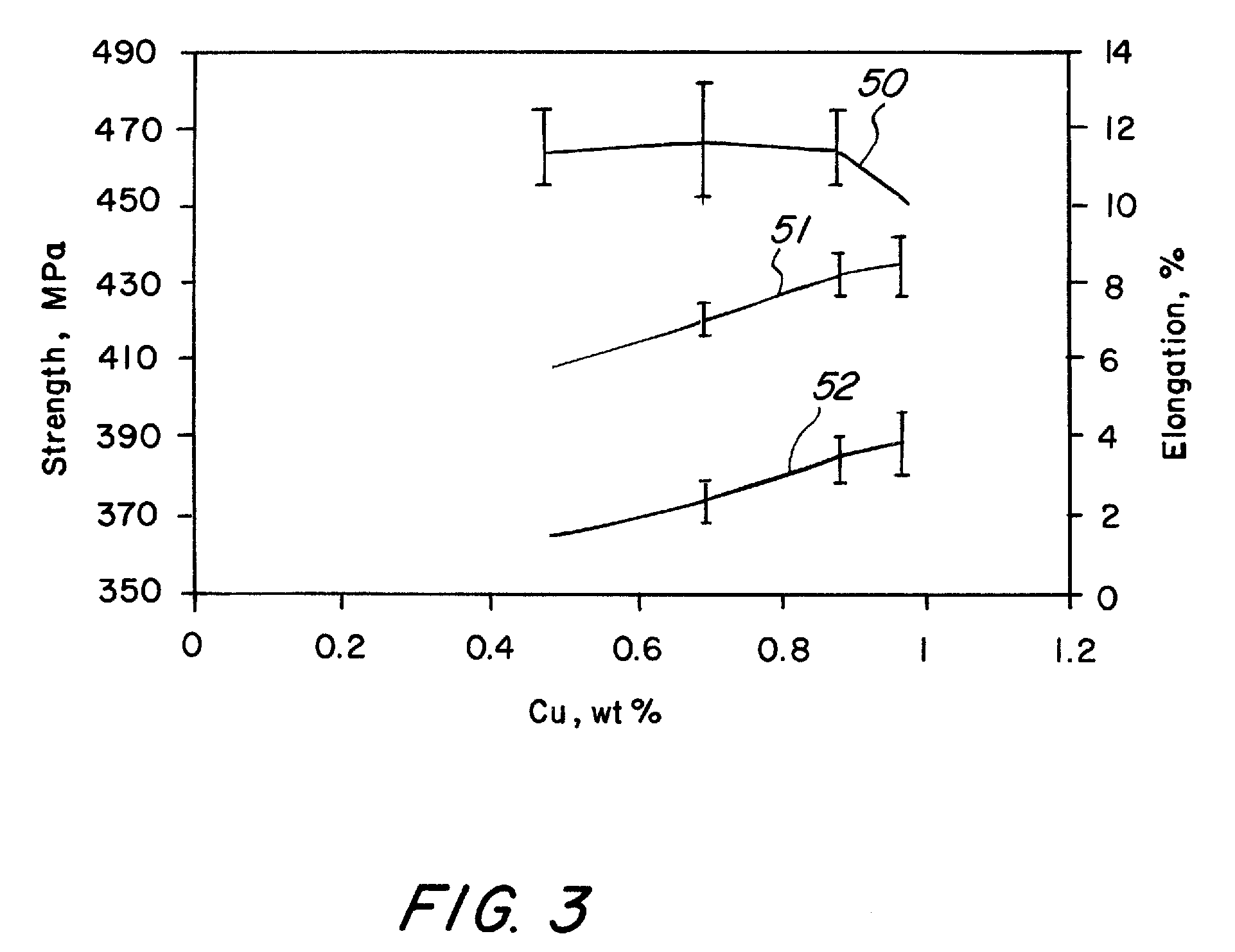

[0040]The present invention provides an Al—Zn—Mg—Cu alloy having yield strengths, fatigue strength, general corrosion performance, and stress corrosion cracking (SCC) performance suitable for automotive and aerospace applications, while maintaining castability. All component percentages herein are by weight percent unless otherwise indicated. When referring to any numerical range of values, such ranges are understood to include each and every number and / or fraction between the stated range minimum and maximum. A range of about 0.5-1.2 wt. % Cu, for example, would expressly include all intermediate values of about 0.6, 0.7, 0.8 and all the way up to and including 1.1 wt. % Cu. As used herein, the term “incidental impurities” refers to elements that are not purposeful additions to the alloy, but that due to impurities and / or leaching from contact with manufacturing equipment, trace quantities of such elements being no greater than 0.05 wt. % that may, nevertheless, find their way into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com