Tire subsection-heating mold

A tire mold and segmental heating technology, applied in the field of tire manufacturing, can solve the problems of affecting the overall quality of tires, reducing service life, and difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

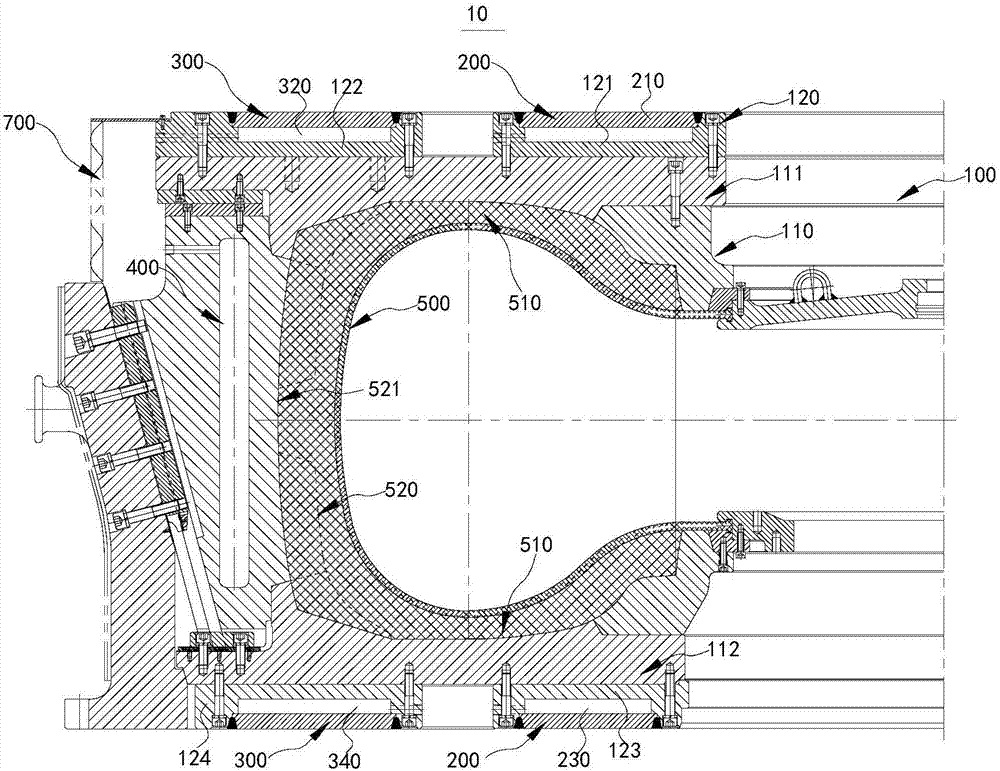

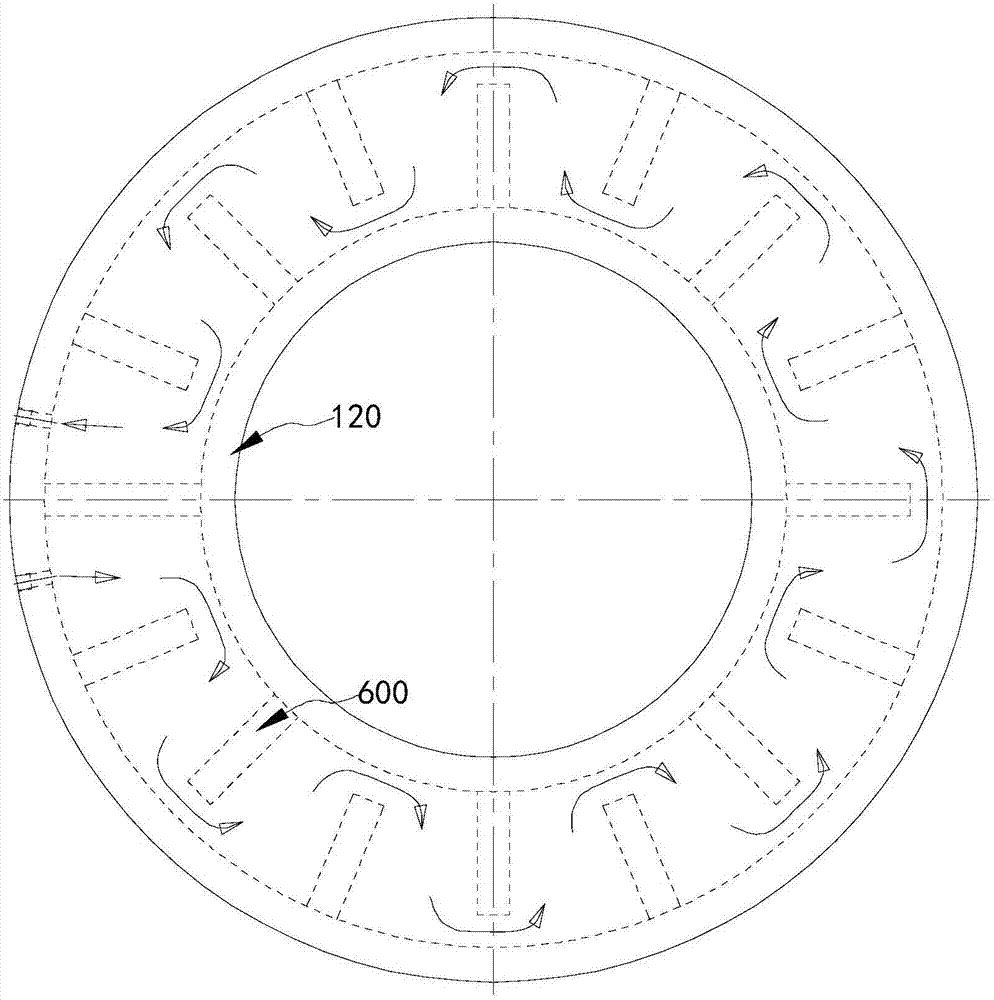

[0055] Please refer to figure 1 , figure 1 It is a schematic structural diagram of a segmented heated tire mold 10 provided by an embodiment of the present invention. From figure 1 It can be seen that a segmented heated tire mold 10 includes an inner steam chamber 200 , an outer steam chamber 300 and a tread 521 steam chamber 400 all disposed on the mold body 100 .

[0056] The inner steam chamber 200 is facing the radially innermost part of the green tire 500; starting from the radial center of the green tire 500, the radial position of the innermost steam chamber wall of the inner steam chamber 200 is less than or equal to the radial position of the green tire 500 The innermost position in the radial direction; the outer steam chamber 300 is located on the outer side of the inner steam chamber 200 in the radial direction of the mold; starting from the radial center of the green tire 500, the radial direction of the outer steam chamber 300 can cover the top 520 of the green...

Embodiment 2

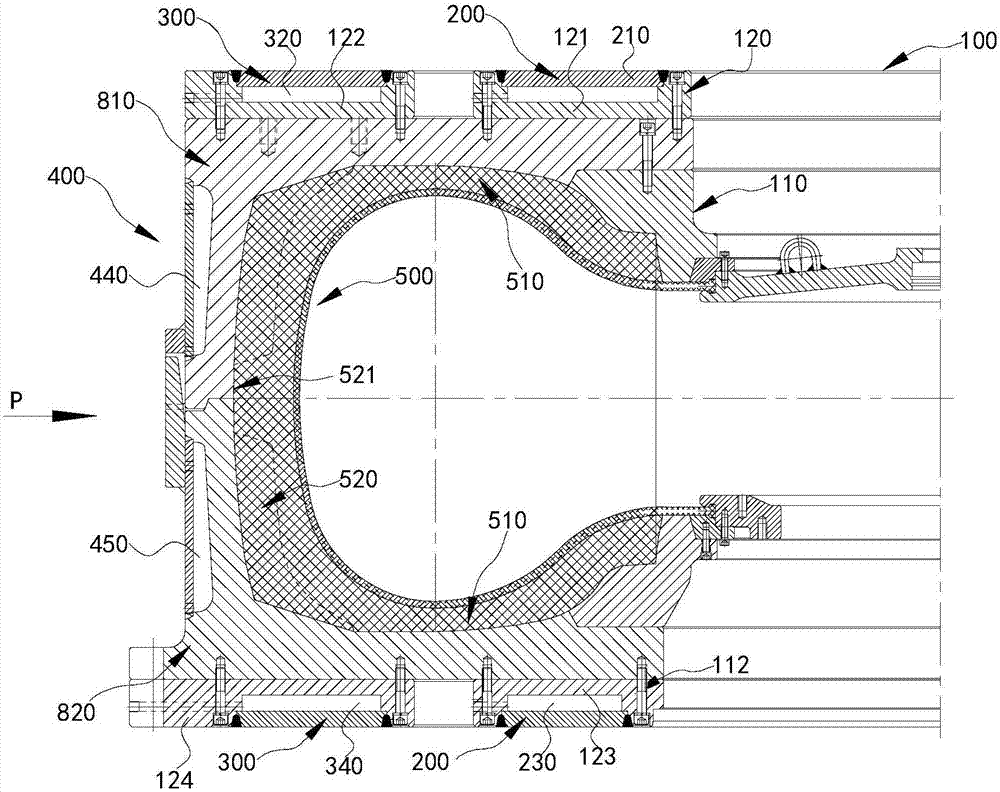

[0080] Please refer to image 3 , image 3 This embodiment of the present invention provides a structural schematic diagram of a segmented heated tire mold. Figure 4 for image 3 Schematic diagram of the structure in the P direction.

[0081] The segmented heated tire mold in this embodiment is substantially the same as the segmented heated tire mold 10 in Embodiment 1, the difference is that the segmented heated tire mold in this embodiment has two halves.

[0082]Further, the first hot plate 121 and the second hot plate 122 are all arranged on the outer surface of the upper mold body 810; the third hot plate 123 and the fourth hot plate 124 are all arranged on the outer surface of the lower mold body 820; 521 The steam chamber 400 is respectively arranged on the side of the tire top 520 of the upper mold body 810 and the side of the tire top 520 of the lower mold body 820 .

[0083] Optionally, the tread 521 steam chamber 400 includes opposite fifth steam chamber 440 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com