Wear-resistant type shirt cuff fabric

A wear-resistant and shirt technology, applied in the field of textile fabrics, can solve the problems of inability to cover peculiar smell and poor wear resistance, and achieve the effect of increasing smoothness, good moisture absorption and softness, and good promotion and utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

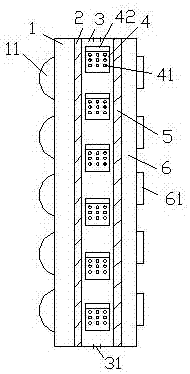

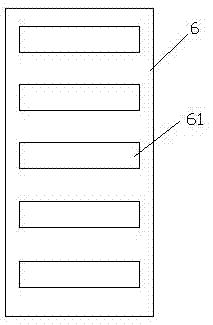

[0019] Such as figure 1 , figure 2 As shown, the structure of this kind of wear-resistant shirt cuff fabric includes an outer polyester fabric layer 1 , and a number of flax fiber protrusions 11 are provided on the outer surface of the polyester fabric layer 1 . When in use, the polyester fabric layer gives the fabric good flexibility and the linen fiber bumps give it good moisture-wicking softness.

[0020] In the above embodiment, specifically, the inside of the polyester fabric layer 1 is provided with a first plastic sheet 2, the inside of the first plastic sheet 2 is provided with a hollow cavity 3, and the side wall of the hollow cavity 3 is provided with a There are several first through holes 31 . When in use, the first plastic sheet layer can increase the flatness of the fabric, and can store ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com