Shaft end jack

A shaft end and sheath technology, which is applied in the field of shaft end sheaths, can solve problems such as easy damage, damaged shaft ends, and affecting accuracy, and achieves the effect of convenient and reliable use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

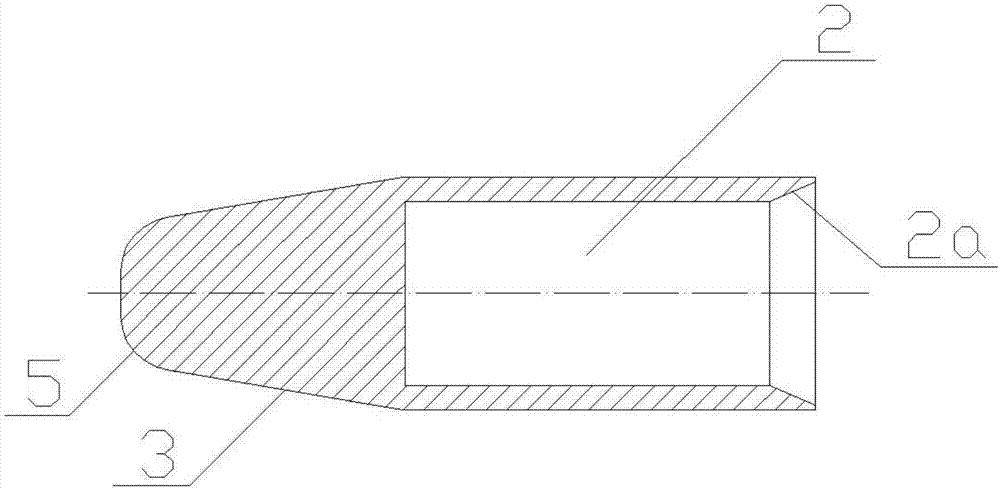

[0014] like figure 1 As shown, the shaft end sheath corresponding to a preferred embodiment of the present invention has a cylindrical shape as a whole, and an accommodation hole 2 for accommodating the shaft end 1 is opened in the center of one end, and a tapered surface 3 is provided at the other end, and the tapered surface 3 The transition to the end face 4 of this end is via a rounded corner 5 . The diameter of the accommodation hole 2 is slightly larger than the diameter of the shaft end 1, and a chamfer 2a is provided at the entrance to facilitate the entry of the shaft end 1. The depth of the accommodation hole 2 is preferably slightly greater than the length of the shaft end 1.

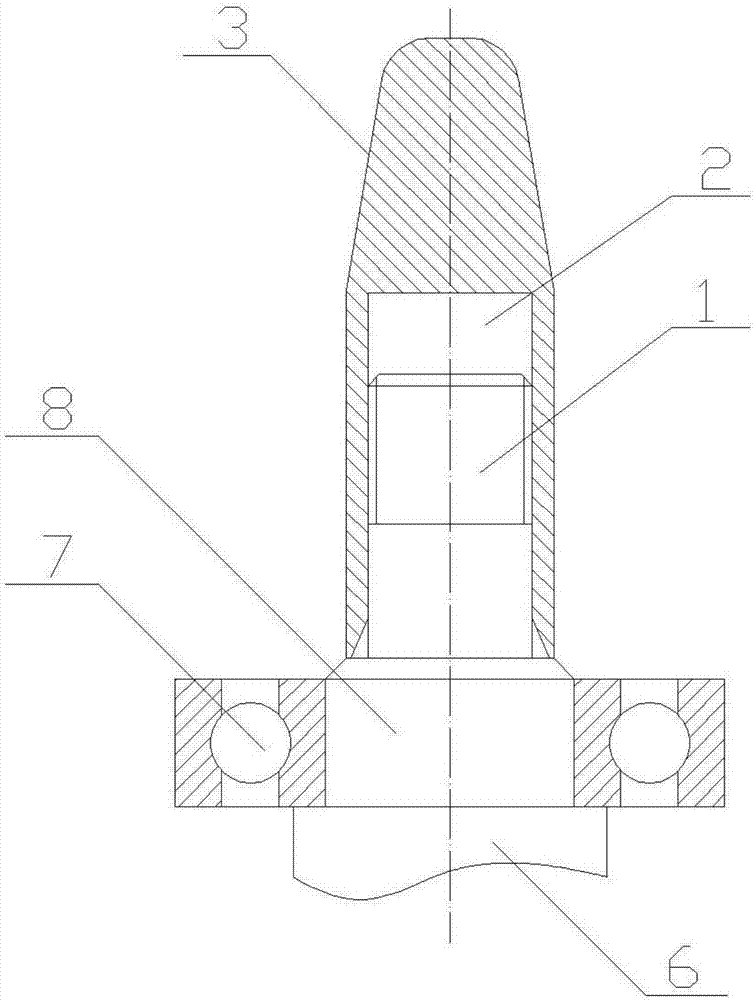

[0015] like figure 2 As shown, the shaft 6 includes a threaded shaft end 1 and a shaft portion 8 on which the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com