Hollow cement brick transferring device

A technology of transfer device and cement brick, which is applied in the direction of transportation and packaging, manual conveying device, etc., and can solve the time-consuming and labor-intensive problems of hollow bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further detailed explanation through specific implementation mode below:

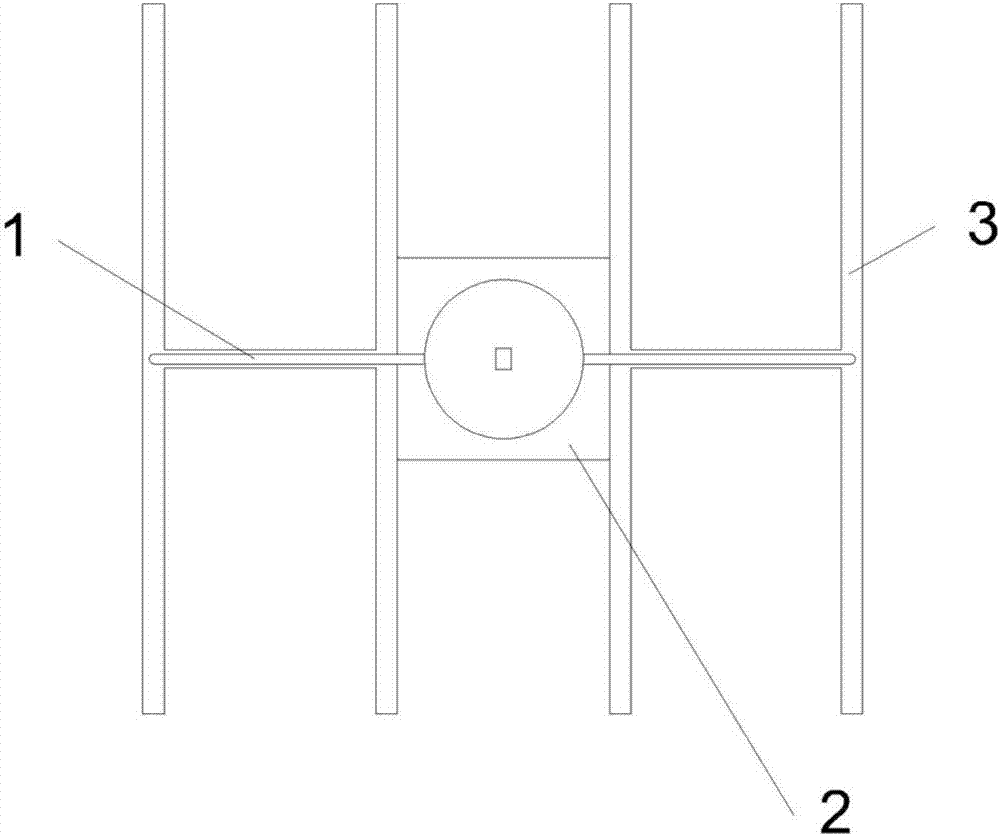

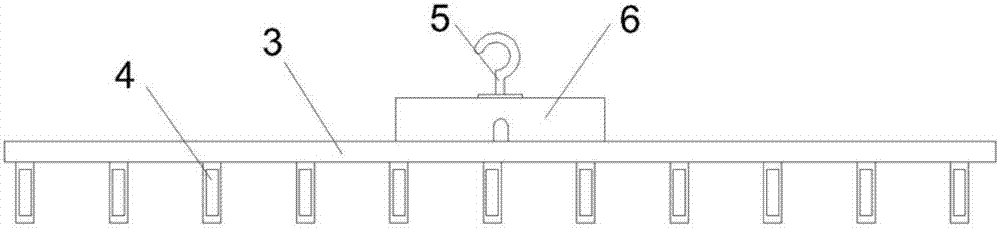

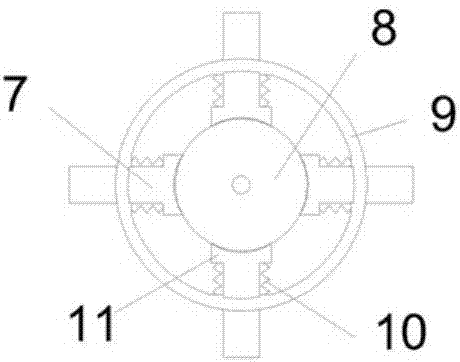

[0016] The reference signs in the drawings of the description include: air pipe 1, platform 2, vertical beam 3, dilator 4, hook 5, air pump 6, fixed teeth 7, expansion bag 8, fixed column 9, spring 10, wing plate 11 .

[0017] The embodiment is basically as attached Figure 1~3 Shown: a hollow cement brick transfer device, including a steel frame, the steel frame includes a beam and four vertical beams 3, the vertical beams 3 are evenly arranged on the beams, vertically connected to the vertical beams 3 are eleven Dilator 4; the dilator 4 includes a fixed column 9, the inside of which is a hollow structure, and four through holes are provided on the surface circumference of the fixed column 9, and a layer of rubber sleeve is provided on the edge of the through hole, and the gap fits in the through hole There are rectangular fixed teeth 7, the fixed teeth 7 include a free end and a connecting en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com