Boring bar based on friction damping

A technology of friction damping and vibration damping structure, applied in boring bars and other directions, can solve problems such as only more than 100 Hz, and achieve the effect of suppressing chatter vibration, simple structure and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

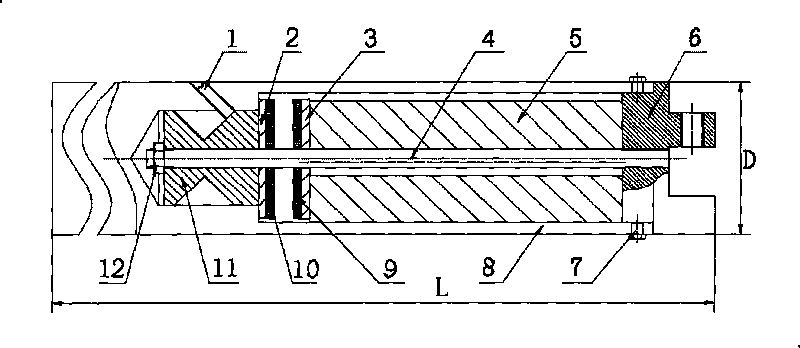

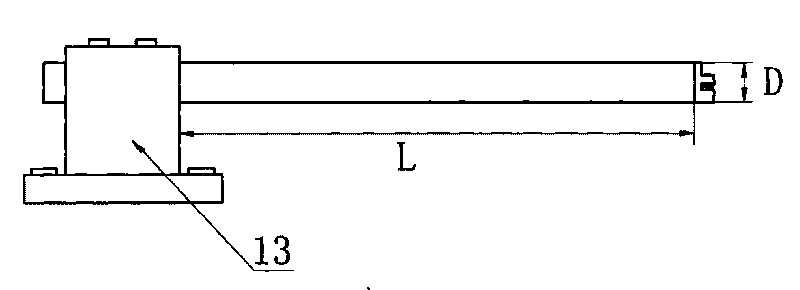

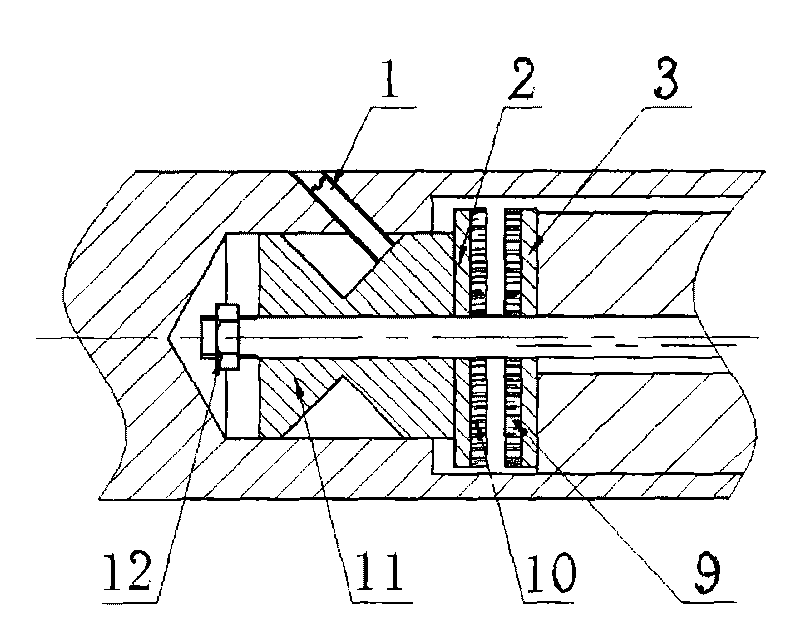

[0020] The boring bar structure includes a boring bar 8 and a boring head 6 fixed on the right end of the boring bar 8. In this embodiment, there is a cavity inside the front end of the boring bar, and the damping structure is arranged in the cavity. Vibration-absorbing structures such as figure 1 As shown, it includes a pusher 11 , an adjusting screw 1 , a washer 2 , a second permanent magnet 10 , a first permanent magnet 9 , a friction plate 3 , a friction vibrator 5 and a guide rod 4 . Wherein, the left end of the guide rod 4 is threadedly fixed with a nut 12 , the right end of the guide rod 4 is threadedly connected with the boring head 6 , and the boring head 6 is also fixedly connected with the boring bar 8 . The pusher 11, spacer 2, second permanent magnet sheet 10, first permanent magnet sheet 9, friction sheet 3 and friction vibrator 5 are set on the guide rod 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com