A cabinet resistant to high and low frequency impact

A high-frequency and low-frequency, cabinet technology, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, etc., can solve the problem that the cabinet cannot resist high and low frequency at the same time, achieve the effect of light weight, reduce vibration and impact, and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

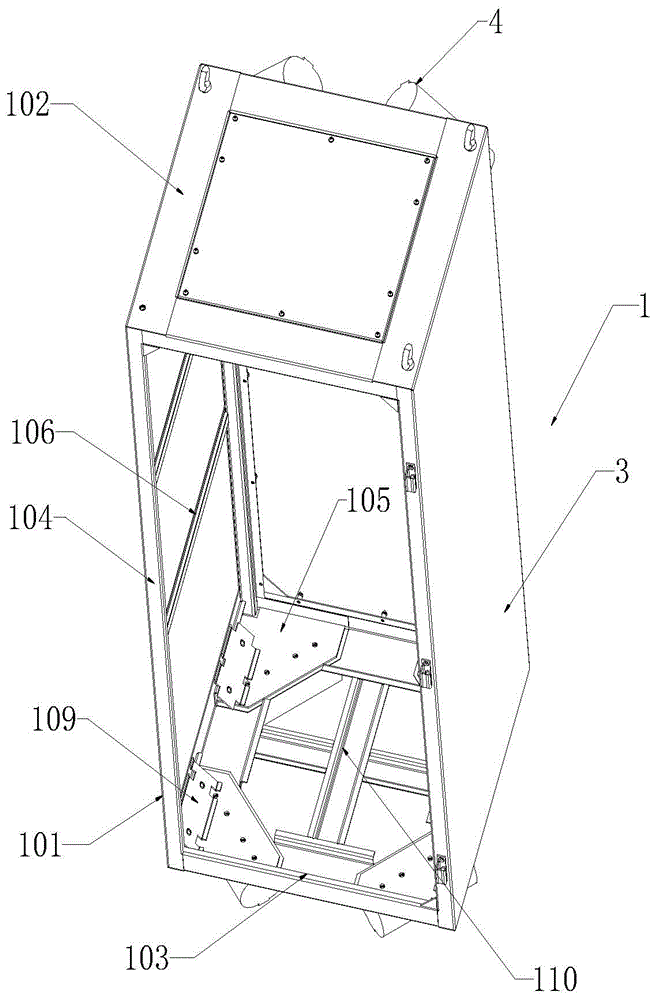

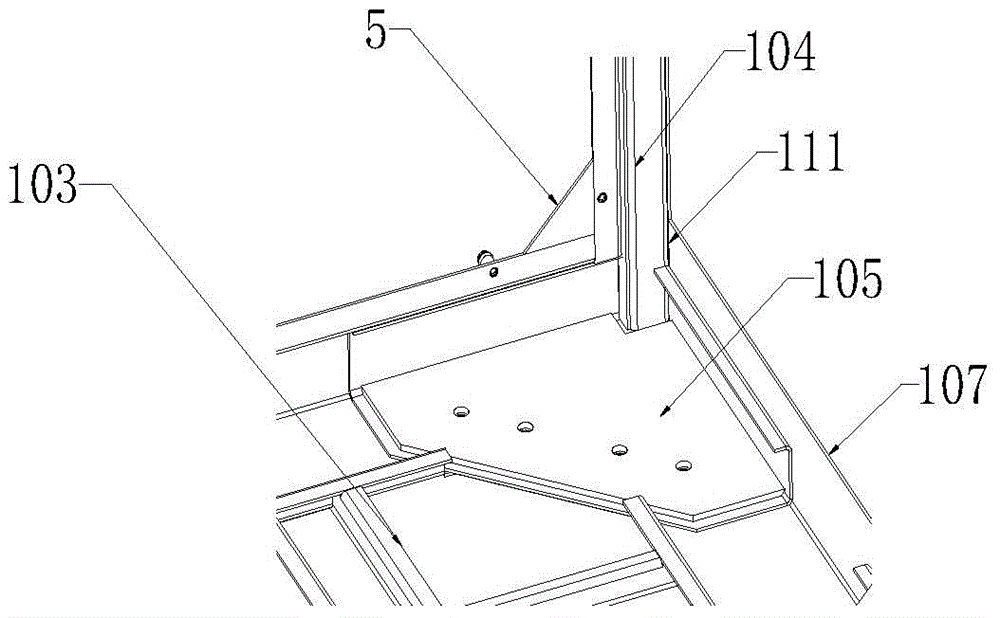

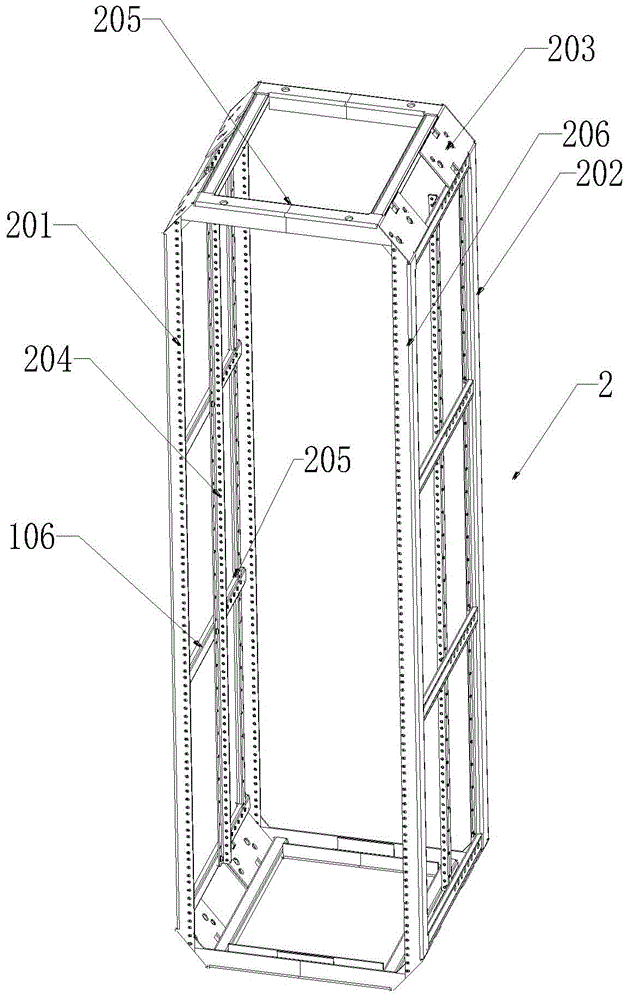

[0031] Such as figure 1 , 3 As shown, the high and low frequency impact resistant cabinet of the present invention includes an outer frame 1 and an inner frame 2 installed inside the outer frame, the outer frame 1 is covered with a cabinet board 3, and the position where the outer frame 1 contacts the ground and / or the wall A shock absorber 4 is arranged at the place, and the inner frame 2 is fixed in the outer frame 1 through the shock absorber 4 . The outer frame 1 is in contact with the installation point through the shock absorber 4, changing the hard contact between the original cabinet and the installation point to an elastic contact, so that the low-frequency impact on the cabinet is reduced, and the inner frame 2 and the outer frame 1 are also elastic. The shock absorber 4 is connected, so that the high-frequency impact on the inner frame 2 is further reduced, and the safety of various electronic devices installed in the inner frame is guaranteed to the greatest exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com