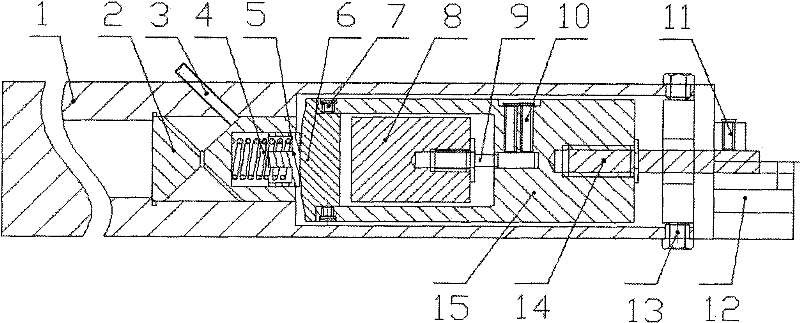

Double-stage tuned mass damper vibration damping-based boring rod structure

A mass tuning and damper technology, applied in the field of damper vibration reduction, can solve the problems of limited number of dampers, unsatisfactory vibration suppression effect, etc., and achieve the effect of suppressing the occurrence of flutter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

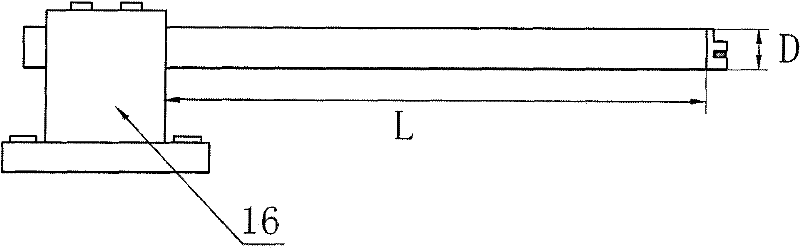

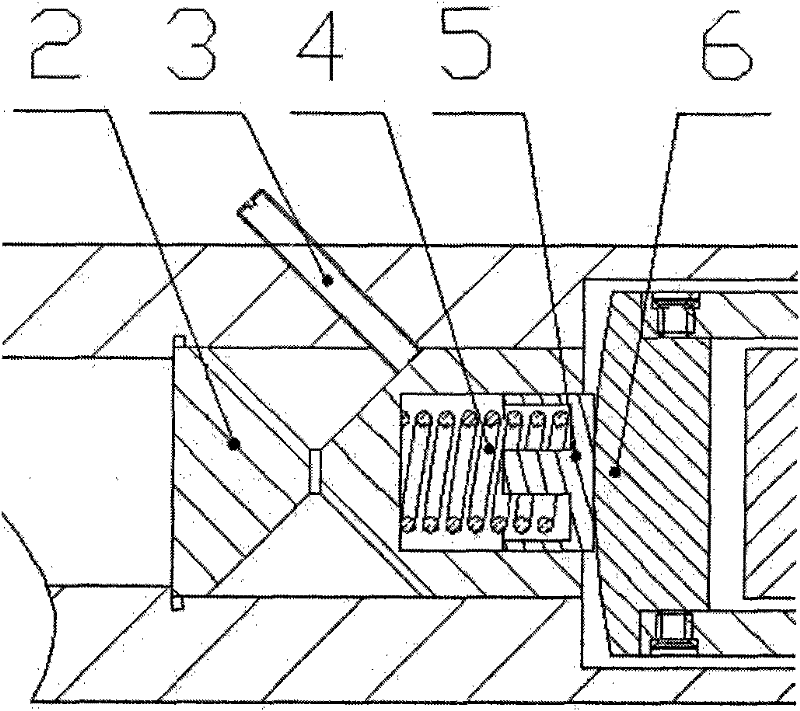

[0020] first as figure 1 , the boring bar structure based on the double-stage mass tuned damper vibration reduction of the present invention includes a boring bar 1, the front end of the boring bar 1 has an inner hole, and the first support rod 14, the second support rod 9, The first damping vibrator 15, the second damping vibrator 8, the damper cover 6, the pusher 2; the end of the first support rod 14 protrudes from the end of the boring bar 1 and fits with the boring bit head 12, and is fixed by screws 11. The other end of the first support rod 14 is threadedly connected to one end of the first damping vibrator 15, and the other end of the first damping vibrator 15 has a concave cavity, and the end of the concave cavity is closely matched with the damper cover 6, and is formed by four The 90° countersunk head screw is fixed with the nail 7; the first damping vibrator 15 is connected to the second damping vibrator 8 through the second support rod 9, and the second support ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com