Flexible conductive adhesive horizontal vibration conveying device

A vibrating conveying and conductive adhesive technology, applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of low production efficiency, large friction force of conductive adhesive, and inability to transmit, so as to solve the problem of difficult positioning and easy maintenance. , the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

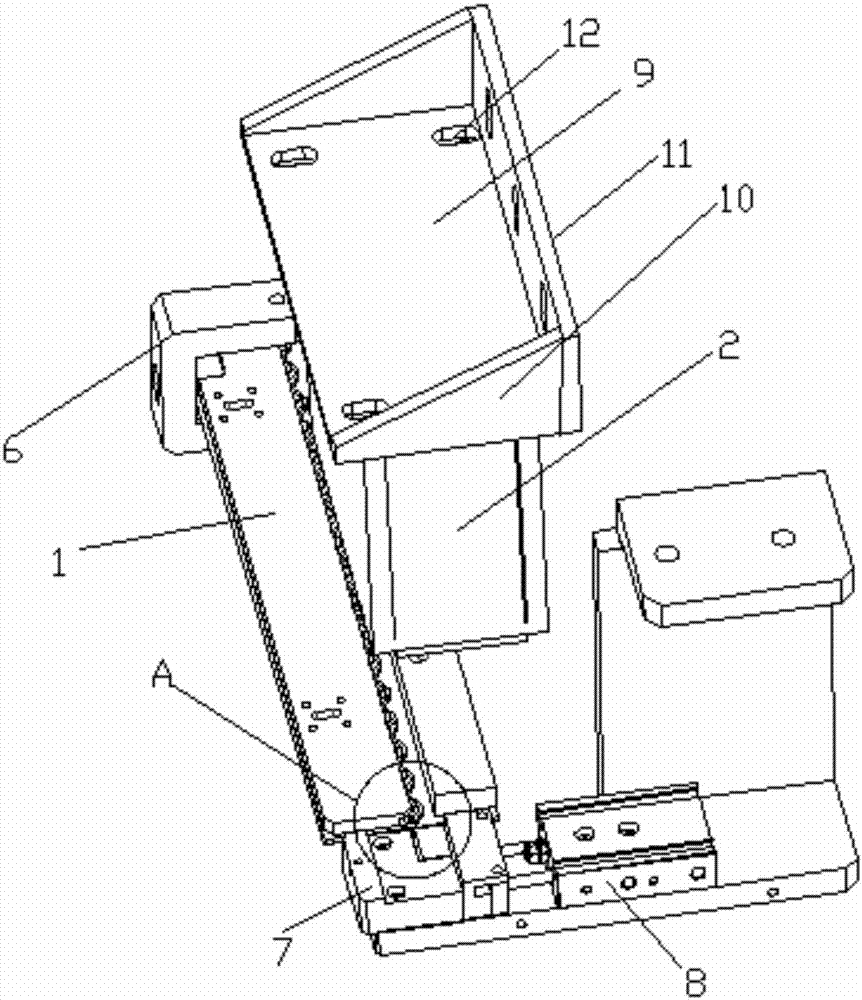

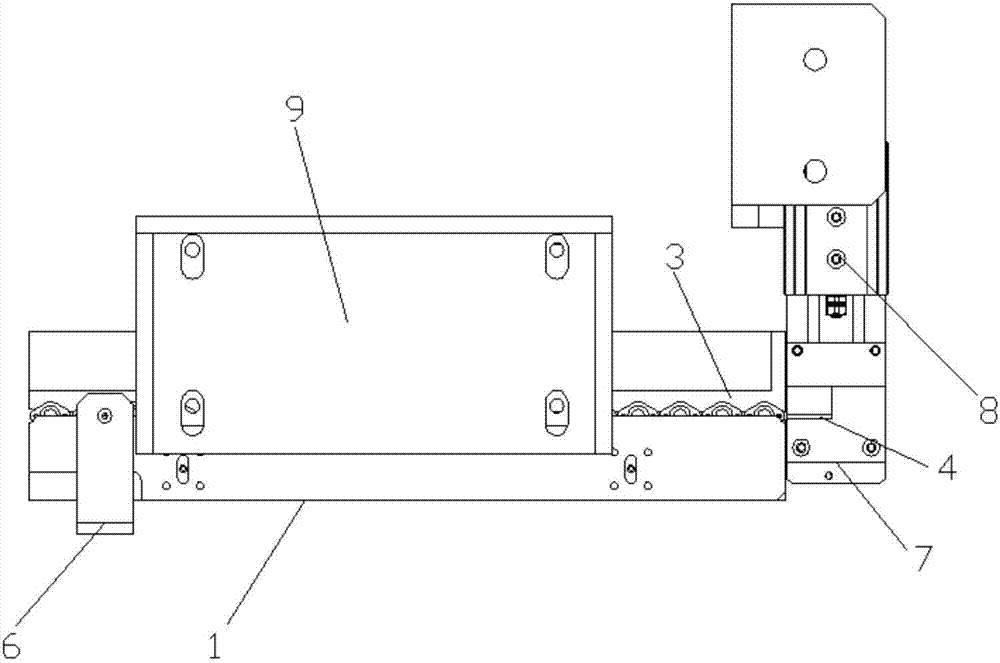

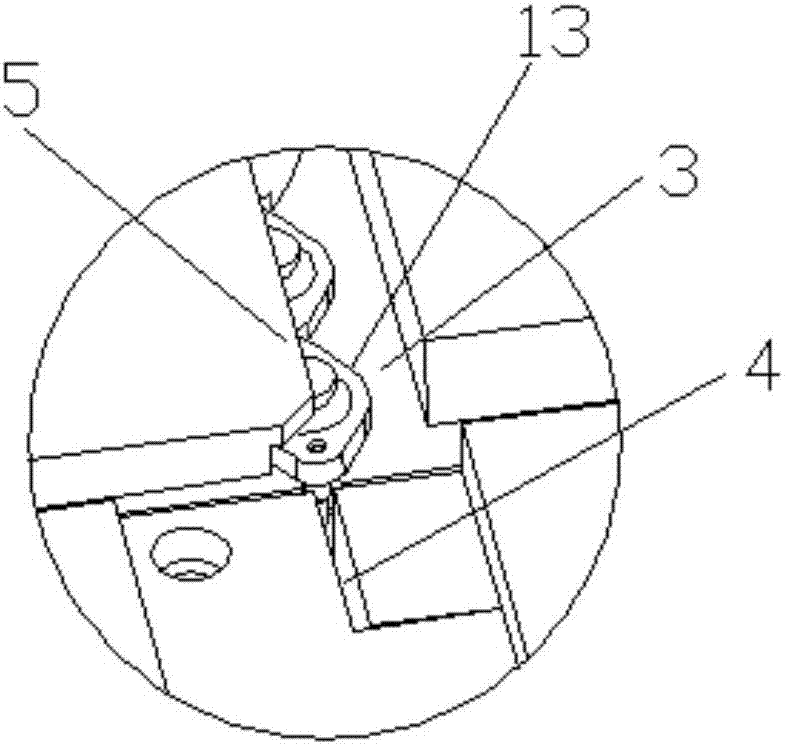

[0018] like Figure 1 to Figure 3 As shown in the figure, a flexible horizontal vibration conveying device for conductive adhesive includes a linear conveying track 1 and a vibrator 2 installed on the linear conveying track 1. The upper plane of the linear conveying track 1 is provided with a connection from one end of the linear conveying track 1 to the The groove 3 at the other end, the bottom of the groove 3 is provided with a slideway 4 which is communicated from one end of the groove 3 to the other end, and the conductive glue 13 for restricting the transport of the slideway is provided directly above the slideway 4 from the slideway 4 When the vibrating conductive adhesive limit baffle 5 and vibrator 2 vibrate the linear conveying track 1, since the shape of the flexible condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com