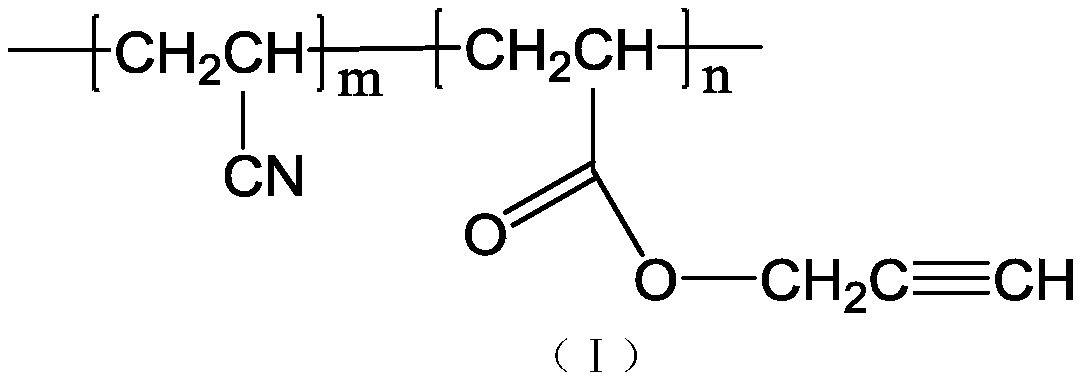

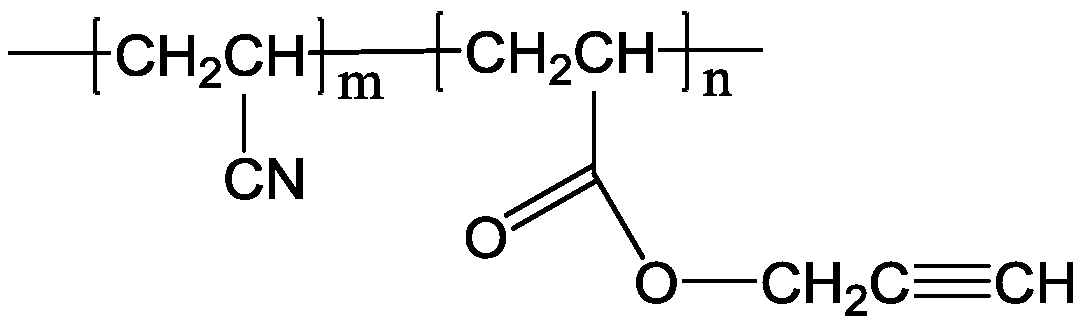

A macromolecular bonding agent suitable for polytriazole crosslinking curing system and its preparation method and application

A cross-linking curing, polytriazole technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of carboxylic acid nitrile and other directions, can solve the problems of no change, poor application effect, poor application effect, etc. Interfacial interaction, the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] Preparation of propynyl acrylate

[0018] The four-neck flask was equipped with mechanical stirring, reflux condenser, thermometer and addition funnel, and was cooled with ice water. First add 27.6mL of propynyl alcohol, 136mL of dichloromethane, and 66.4mL of triethylamine. After cooling to below 5°C, slowly add a mixed solution of 40mL of acryloyl chloride and 40mL of dichloromethane dropwise. The reaction is exothermic, and the dropwise addition is controlled so that the reaction temperature does not exceed 30° C. After the dropwise addition is completed, the natural stirring reaction is continued for 4 hours.

[0019] After stopping the reaction, wash with water 3 times, each time with 80 mL of water. After the organic phase was suspended and evaporated under reduced pressure to remove methylene chloride, 0.5 g of hydroquinone was added and transferred to a vacuum distillation device. The collected boiling point was 93 ° C ( 22 kPa) fractions total 51.2g, GC purity...

Embodiment 1

[0022] The preparation of embodiment 1 macromolecule bonding agent

[0023] In a four-neck flask equipped with electromagnetic stirring, reflux condenser, thermometer and constant pressure dropping funnel, add 6.03g of azobisisobutyronitrile, 100mL of acetone, 59.82g of acrylonitrile, and 5.73g of hydroxyethyl acrylate, and stir to dissolve. Add 9.45g of propynyl acrylate and 30mL of acetone into the constant pressure dropping funnel, and mix well. The temperature of the reaction solution was raised to 65°C, and the propynyl acrylate solution was added dropwise after the reaction solution started to turn white, and the dropwise addition was completed in about 5 hours, and the reaction was continued for 2 hours after the dropwise addition was completed.

[0024] After the reaction, pour the reaction solution into a 500mL beaker and let it stand, pour off the supernatant and wash with absolute ethanol three times, 150mL each time, and then vacuum-dry to obtain a light yellow pow...

Embodiment 2

[0027] In a four-neck flask equipped with electromagnetic stirring, reflux condenser, thermometer and constant pressure dropping funnel, add 7.2g azobisisobutyronitrile, 150mL acetone, 80g acrylonitrile, 12.6g hydroxyethyl acrylate, and stir to dissolve. Add 7.4g of propynyl acrylate and 50mL of acetone into the constant pressure dropping funnel, and mix well. The temperature of the reaction solution was raised to 65°C, and the propynyl acrylate solution was added dropwise after the reaction solution started to turn white, and the dropwise addition was completed in about 5 hours, and the reaction was continued for 2 hours after the dropwise addition was completed.

[0028] After the reaction, pour the reaction solution into a 500mL beaker and let it stand, pour off the supernatant and wash with absolute ethanol three times, 150mL each time, and then vacuum-dry to obtain a light yellow powder. Application of embodiment 3 macromolecule bonding agent

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com