Novel fuel oil distributor applying combined valve element

A technology of fuel distributor and combined spool, which is applied in the direction of fuel valves of gas turbine devices, machines/engines, turbines/propulsion devices, etc., which can solve the problems of heavy processing tasks, unfavorable for engines, and large number of parts, etc., and achieve reduction Effects of machining tasks, reduced number of valve components, reduced product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

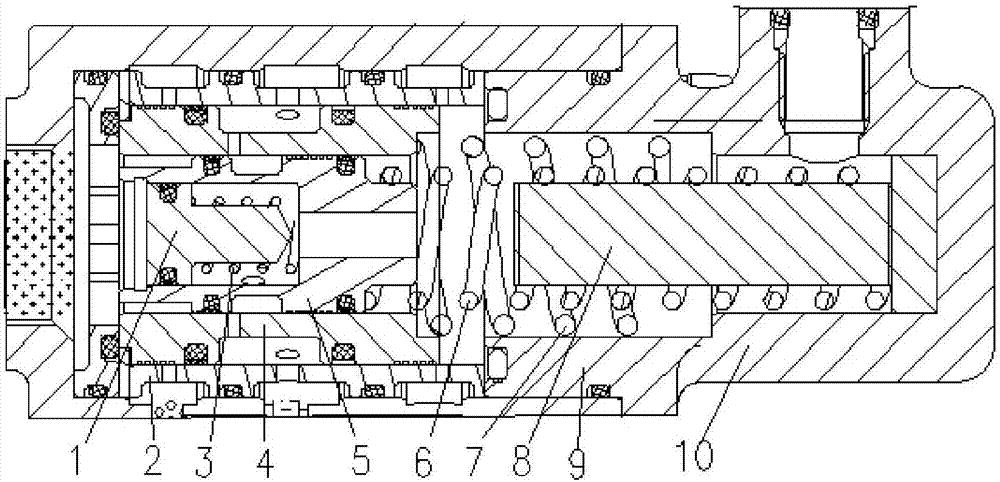

[0014] The combination spool requires strict control over the assembly process. Now take the rightward direction of the inner hole of the shell as the benchmark, such as figure 2 As shown, first install the check valve 1 and the check valve spring 3 into the main oil circuit spool 5 with the tip of the spool facing right to form the main oil circuit spool assembly; then press the main oil circuit spool assembly Install one end of the step in the right direction into the auxiliary oil circuit spool 4 to form the auxiliary oil circuit spool assembly; then install the auxiliary oil circuit spool assembly in the valve sleeve 2 with the end with the inner step facing right to form the valve sleeve assembly; then put the valve sleeve assembly into the housing 9 to the left; finally install the housing cover 10 that has been loaded into the spring seat 8, auxiliary oil circuit spring 7, and main oil circuit spring 6 in sequence on the housing 9. After each installation step, check ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com