A hydrogen annealing furnace tail gas treatment system and its treatment method

A technology for exhaust gas treatment and annealing furnace, which is applied in combustion methods, incinerators, combustion types, etc., can solve problems such as explosion, inability to accurately control the amount of oxygen, and achieve the effects of good safety performance, controllable gas composition, and injury avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

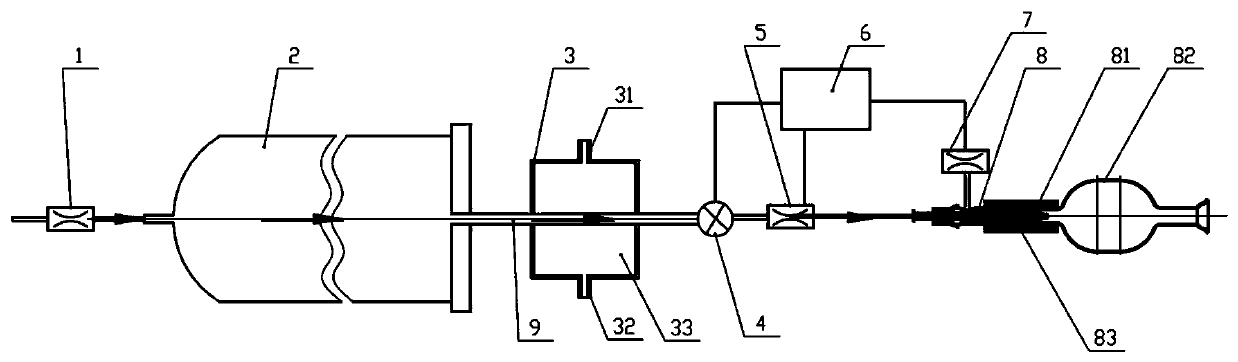

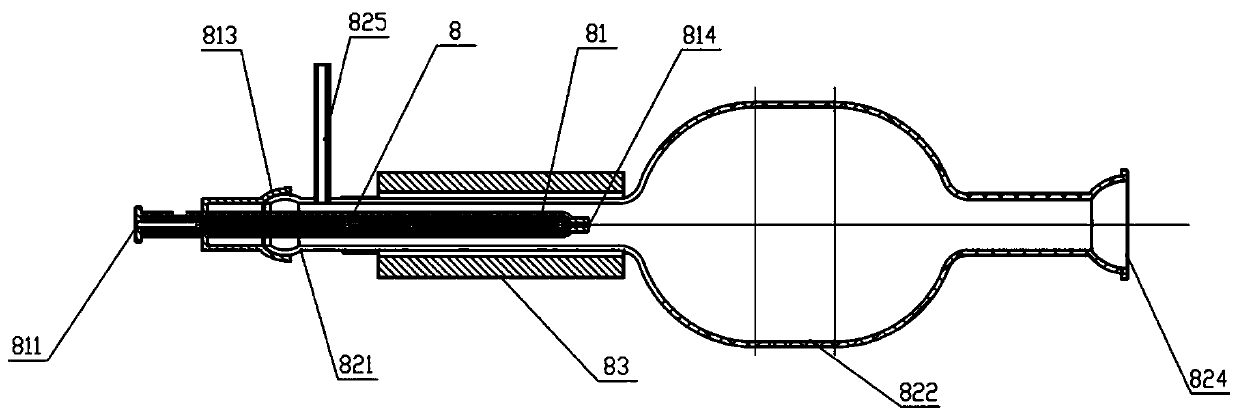

[0041] Such as figure 1As shown, this implementation case is used for hydrogen tail gas treatment of hydrogen annealing furnace, including hydrogen mass flowmeter 1 for intake flow control, process reaction tube 2, tail gas cooling bottle 3, hydrogen concentration detection sensor 4, and gas flow meter 5 , PC controller 6, oxygen mass flow meter 7, hydrogen tail gas combustion device 8 and tail gas outlet pipeline 9. Before the hydrogen is introduced into the hydrogen annealing process, the reaction tube 2 is generally pure nitrogen. As the process continues to advance, the hydrogen mass flowmeter 1 will gradually increase the hydrogen flow rate from 0 until it stabilizes at a certain flow rate. At this time The hydrogen in the tail gas outlet pipeline 9 gradually increases from 0 to the same flow rate as the hydrogen mass flow meter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com