Electronic scale wind cap for testing mass of micro object

A technology of electronic scales and windshields, applied in the field of quality inspection, can solve problems such as difficult nighttime operations, low weighing efficiency, and lack of lighting functions, and achieve the effects of improving weighing efficiency, high degree of automation, and enhancing visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

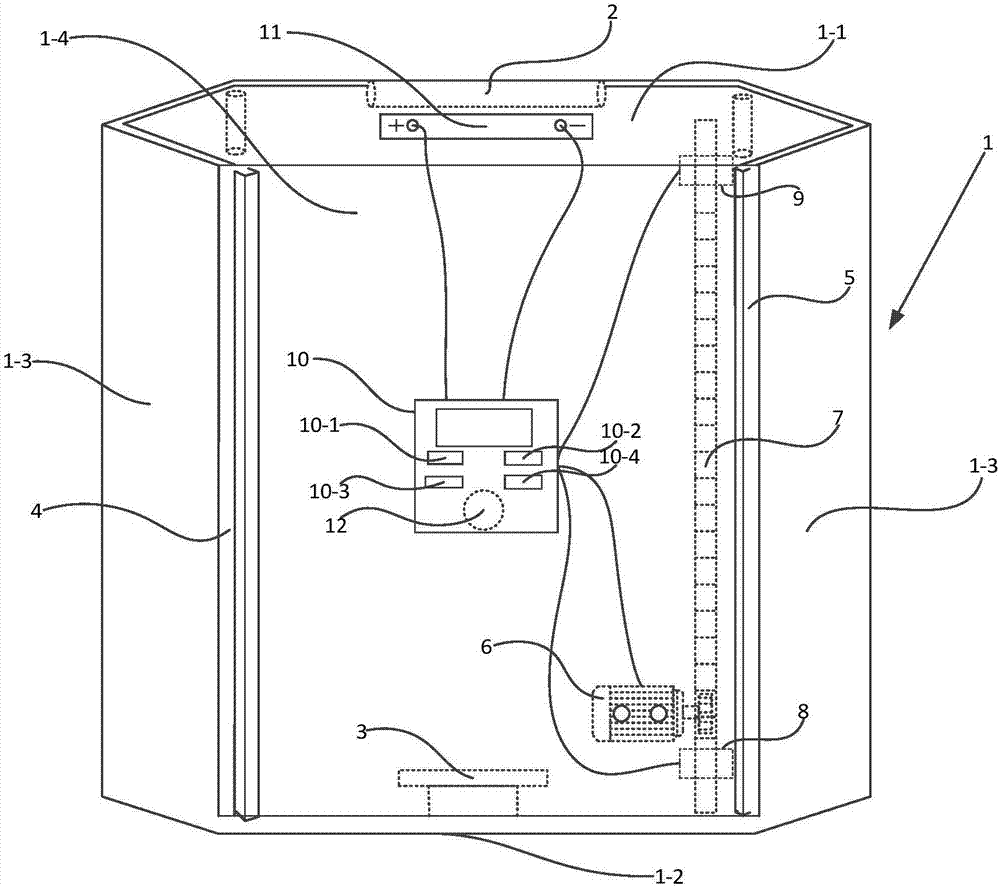

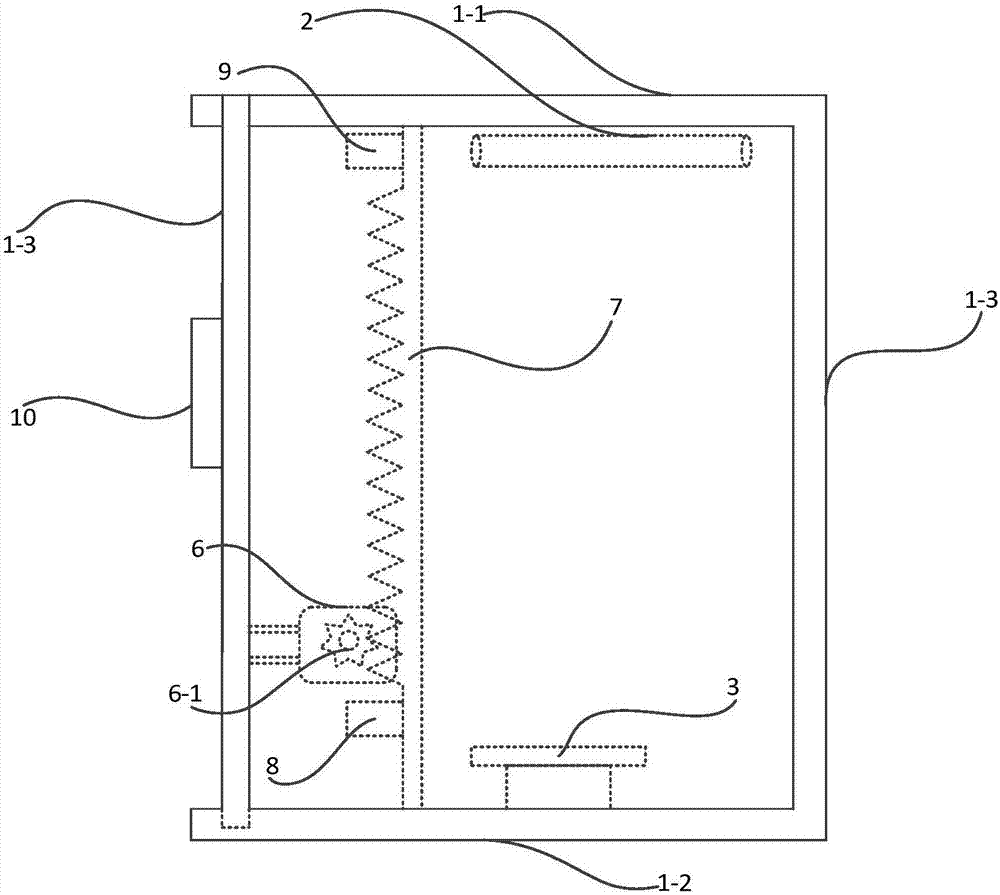

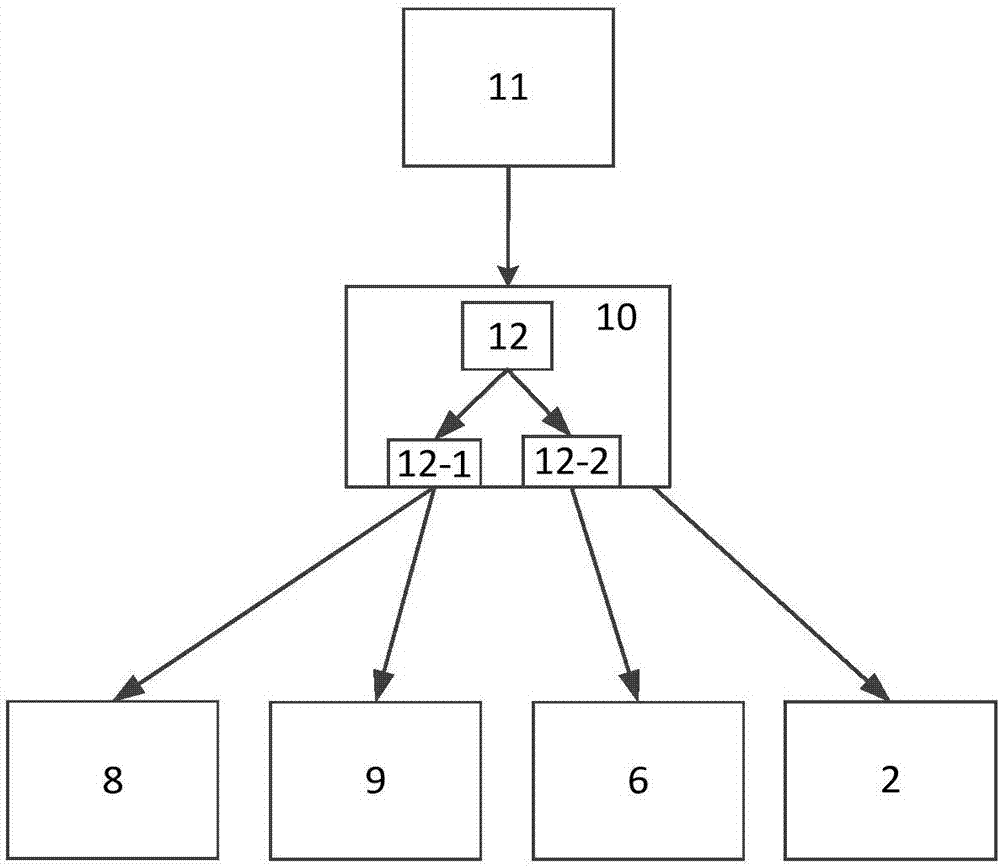

[0034] Embodiment: a kind of electronic scale windshield that is used to detect the quality of tiny objects, such as Figure 1-Figure 2 As shown, a casing 1 is included, and the casing includes an upper bottom surface 1-1, a lower bottom surface 1-2, a side wall 1-3 and a feed hatch 1-4, and the outer surface of the upper bottom surface is fixed with some lighting Lamp 2, the lower bottom surface is provided with a load tray 3 for weighing, the side wall is integrally formed with the upper bottom surface and the lower bottom surface, and the side wall is provided with a left chute 4 and a right chute 5 , the feed hatch is matched with the left and right chute, the inner surface of the feed hatch is fixed with a drive motor 6, and the end of the output shaft of the drive motor is provided with a gear 6-1, including A rack 7 matched with the gear, one end of the rack is fixed on the lower bottom surface, the other end of the rack is fixed on the upper bottom surface, and the rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com