Safety belt tension sensor

A tension sensor and seat belt technology, applied in tension measurement and other directions, can solve the problems that the force sensor cannot perform accurate measurement, the collision strength of the force sensor is not enough, and the force rod cannot be passively rotated, so as to achieve reliable locking and improve measurement accuracy. , Anti-stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] The structure of the present invention is as follows:

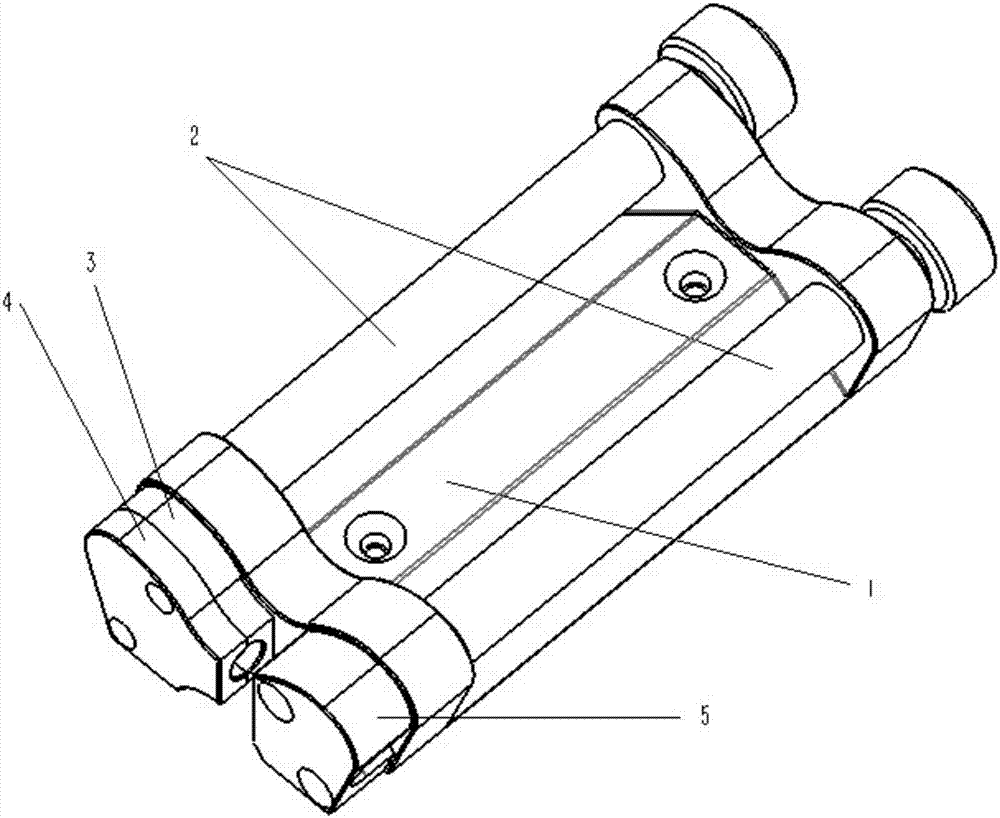

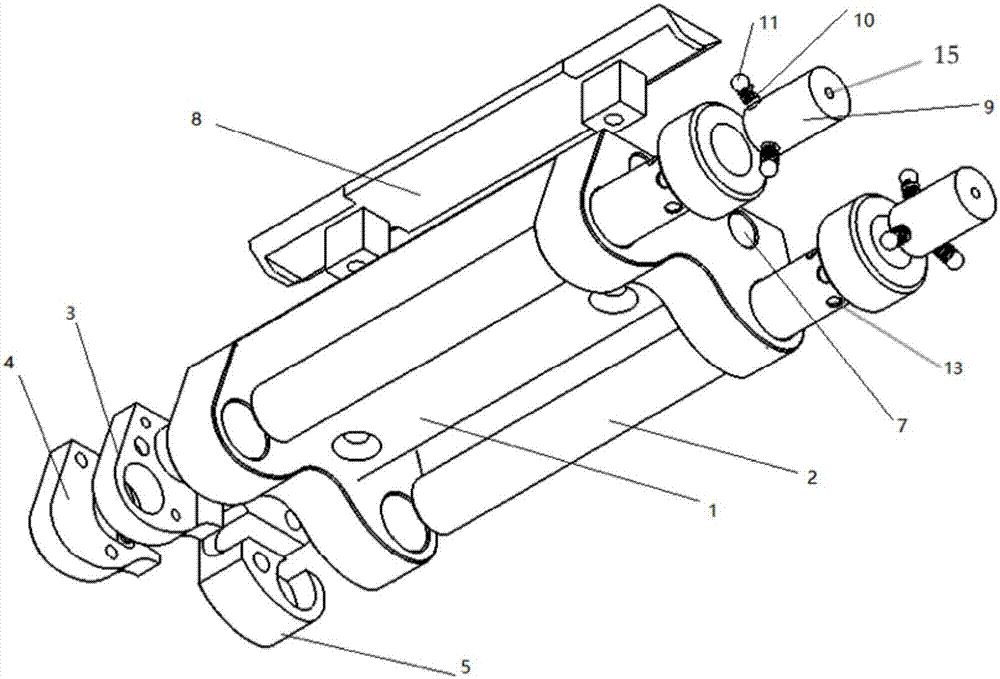

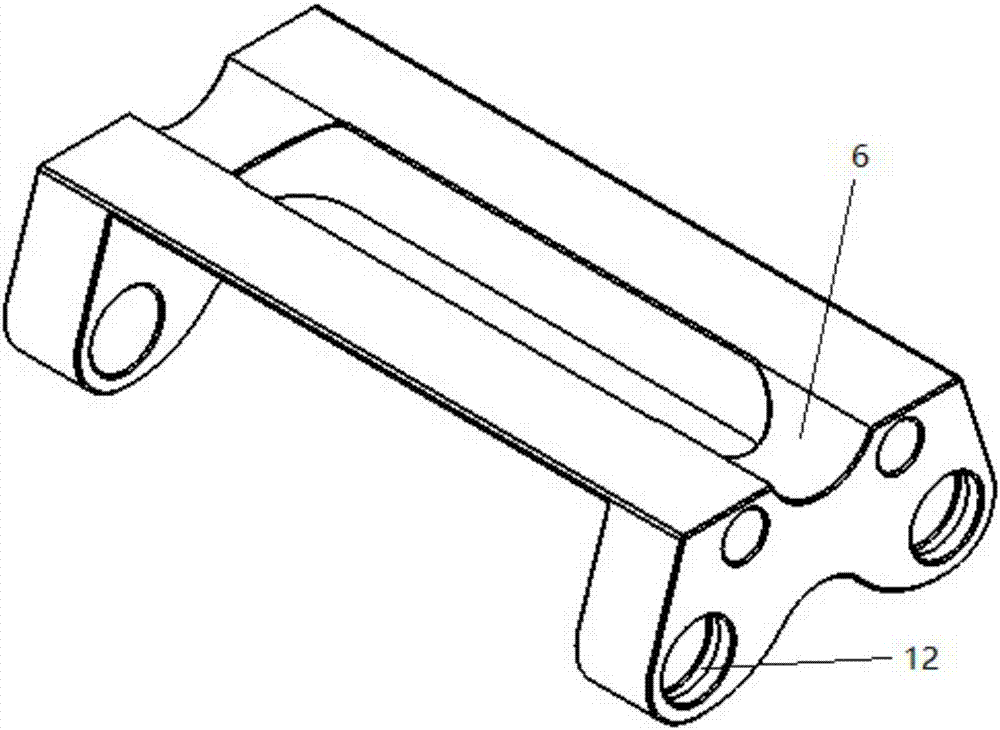

[0029] A safety belt tension sensor, the main body 1 is provided with an upper cover plate 8, the upper part of the main body 1 is also provided with a groove 6, and the groove 6 is used for installing strain gauges, and the inside of one side of the main body 1 An annular clamping groove 12 is provided, and a force-bearing rotatable component is installed in the main body 1, and the force-bearing rotatable component is clamped with the annular clamping groove 12;

[0030] The stressed rotatable parts include a parallel stressed rod 2, a built-in rod 9, an elastic member and a positioning member. The end of the parallel stressed rod 2 is provided with a positioning hole 13, and the positioning hole 13 is located on the outer side of the end. Zhou Mian. The built-in rod 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com