Auto Parts Test Device

A technology of auto parts and testing devices, which is applied in the testing of mechanical parts, measuring devices, testing of machine/structural parts, etc., and can solve problems such as inability to test parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

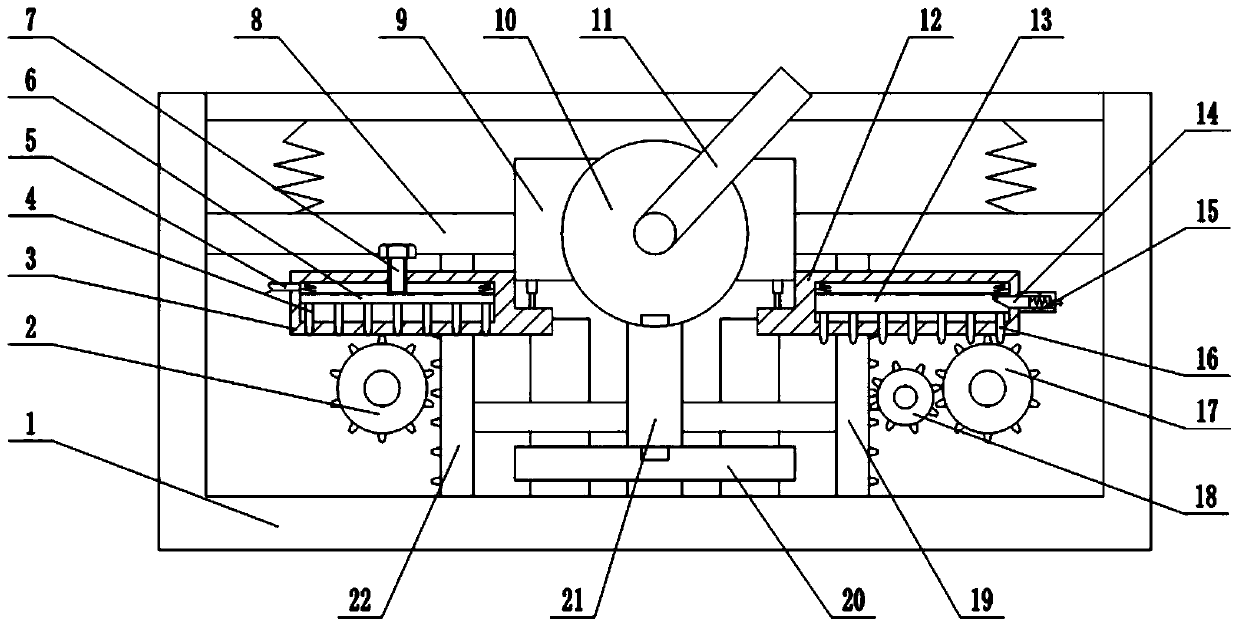

Image

Examples

Embodiment 2

[0020] Embodiment 2 differs from Embodiment 1 in that the driving mechanism is an air cylinder, which is slidably connected to the frame 1, and the upper end of the output rod of the air cylinder is welded to the bottom of the mounting block. Start the cylinder to adjust the upper and lower distances of the mounting block, thereby realizing the adjustment of the vertical distance of the turntable 10, and the adjustment of the cylinder is more flexible, and the adjustment of the lower right side and upper left side of the turntable 10 can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com