Auxiliary tool for assembly pipe machining

A technology for auxiliary tooling and assembly, applied in the direction of workpiece clamping devices, measuring devices, manufacturing tools, etc., can solve the problems of low efficiency of assembly tubes, and achieve the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

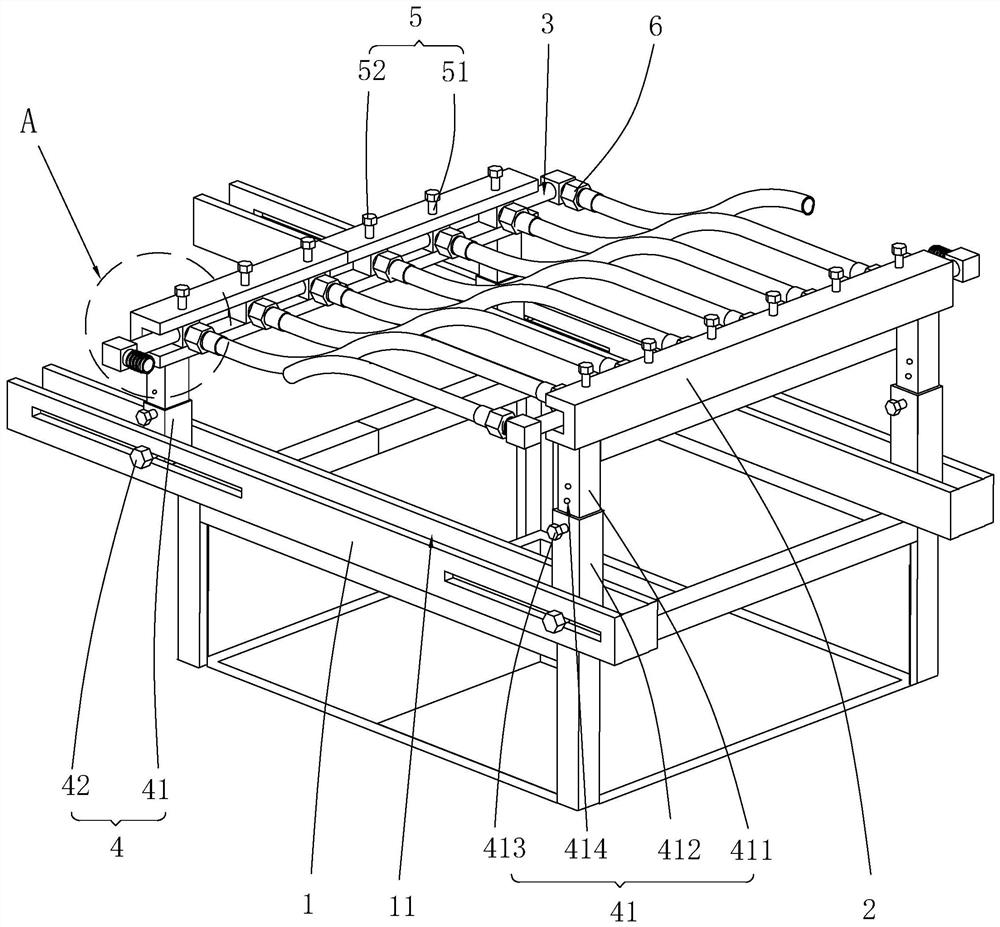

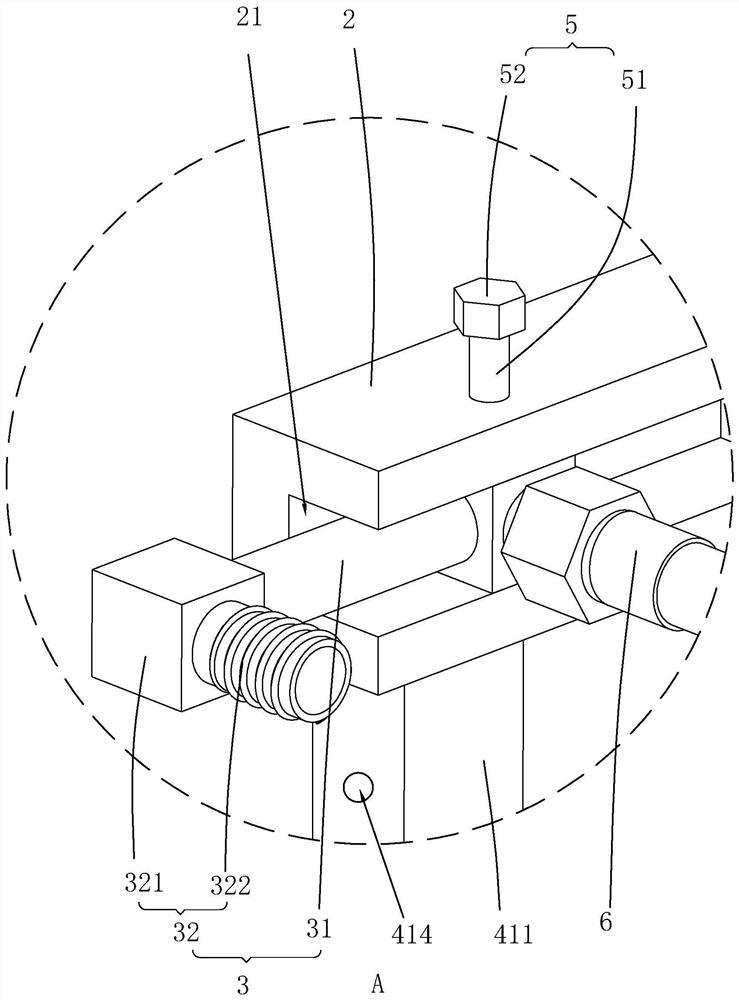

[0034] refer to figure 1 , the auxiliary tooling for assembly pipe processing includes a base 1, a position adjustment mechanism 4, a support frame 2 and an installation mechanism 3, the support frame 2 is installed on the base 1 through a position adjustment assembly, and two support frames 2 are provided and the two are parallel to each other A plurality of installation mechanisms 3 are connected to the support frame 2, and the installation mechanisms 3 are used to connect with the joints 6 of the assembly pipe steel parts.

[0035] refer to figure 1 , the base 1 is provided with a chute 11, the position adjustment mechanism 4 includes a connecting rod 41 and a positioning piece 42, one end of the connecting rod 41 is placed in the chute 11 and is slidably connected with the base 1, the locating piece 42 is set as a bolt, and the bolt passes through the base 1. The side wall abuts against the connecting rod 41 to realize the positioning of the connecting rod 41 in the chute...

Embodiment 2

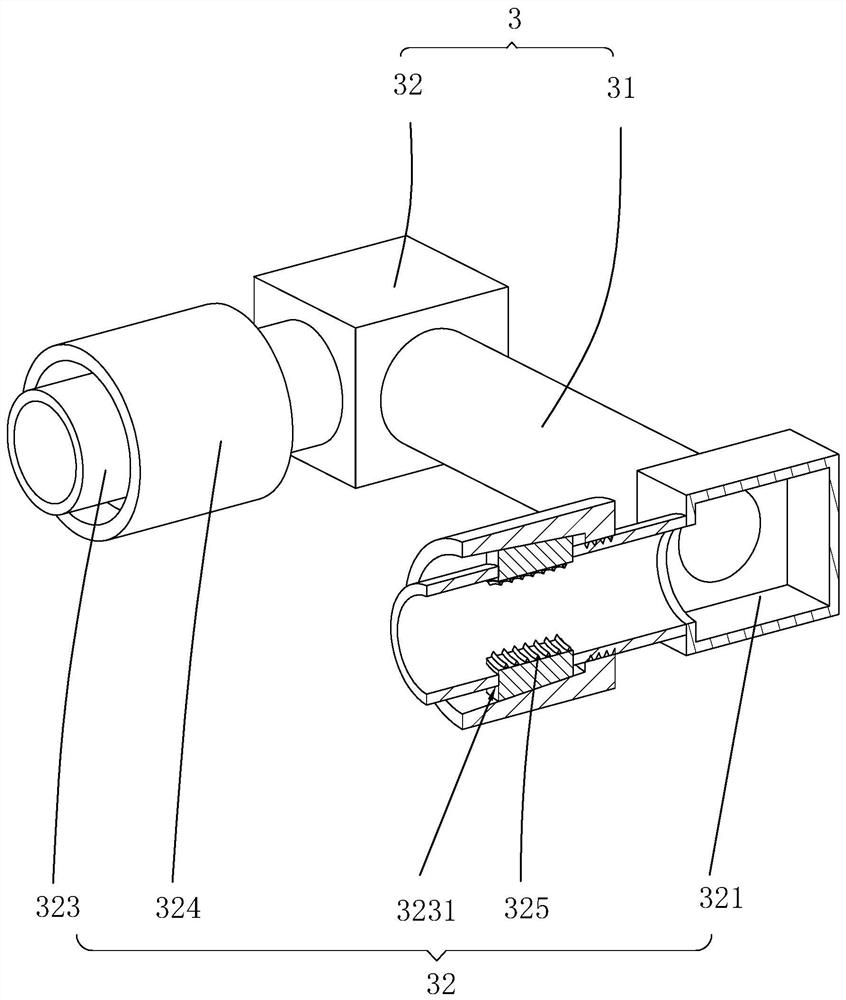

[0041] refer to image 3 The difference between this embodiment and Embodiment 1 is that the mounting member 32 includes a mounting block 321 connected to the connecting sleeve 322, the mounting block 321 is hollow, and the mounting block 321 is welded with an inner sleeve 323 communicating with the inside. The end of the inner sleeve 323 away from the mounting block 321 is provided with a through hole 3231, and a wedge block 325 slidingly connected with the inner sleeve 323 is placed in the through hole 3231. The wedge block 325 has a tendency to slide along the radial direction of the inner sleeve 323. There are two through holes 3231 and two wedge blocks 325 . The side of the wedge block 325 near the outer sleeve 324 is a slope, and the slope of the wedge block 325 is set towards the side of the mounting block 321, and the side of the wedge block 325 away from the outer sleeve 324 is provided with threads for increasing the connection between the wedge block 325 and the ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com