Electric-controlled bar-shaped candy primary forming device

A kind of initial forming, electric control technology, applied in the direction of confectionery, confectionery industry, food science, etc., can solve the problem that the shape and texture of candy can not meet the needs well, do not have progress and breakthrough, and the finished product hygiene index is difficult to achieve and other problems, to achieve the effect of novel structure, diverse and rich shapes, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

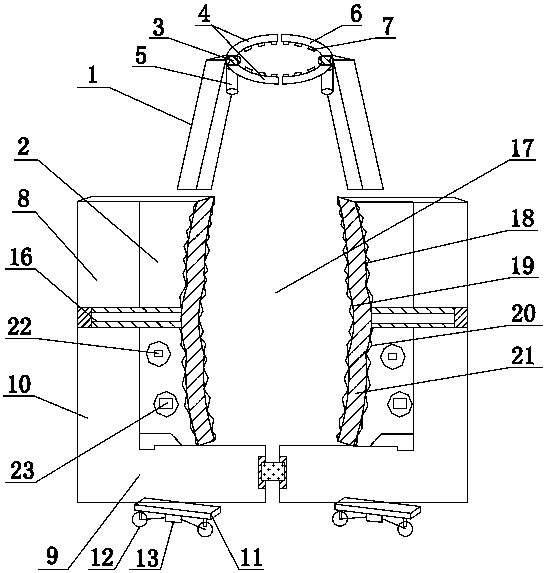

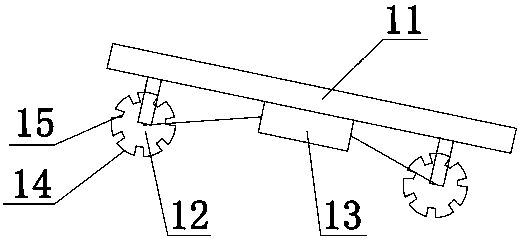

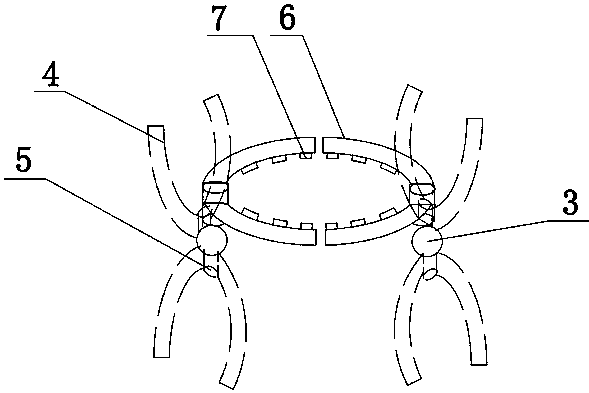

[0032] Such as Figure 1-4 As shown, an electrically controlled bar-shaped candy primary forming device includes a humanoid frame 1, an opening and closing mechanism, an electric control frame body mechanism, a motion mechanism and a special-shaped washboard 2;

[0033] The human-shaped frame 1 and the opening and closing mechanism of the present invention are innovative and outstanding, and the two cooperate with each other to ensure the stability and safety of the action; the top of the human-shaped frame 1 is provided with the opening and closing mechanism through the horizontal rotation axis I3, and the The opening and closi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com