Automatic wire management device and wire management method for filter coil pins

A technology of a wire management device and a filter coil, applied in the field of automatic wire management devices, can solve the problems of looseness, high labor intensity of manual work, low assembly efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

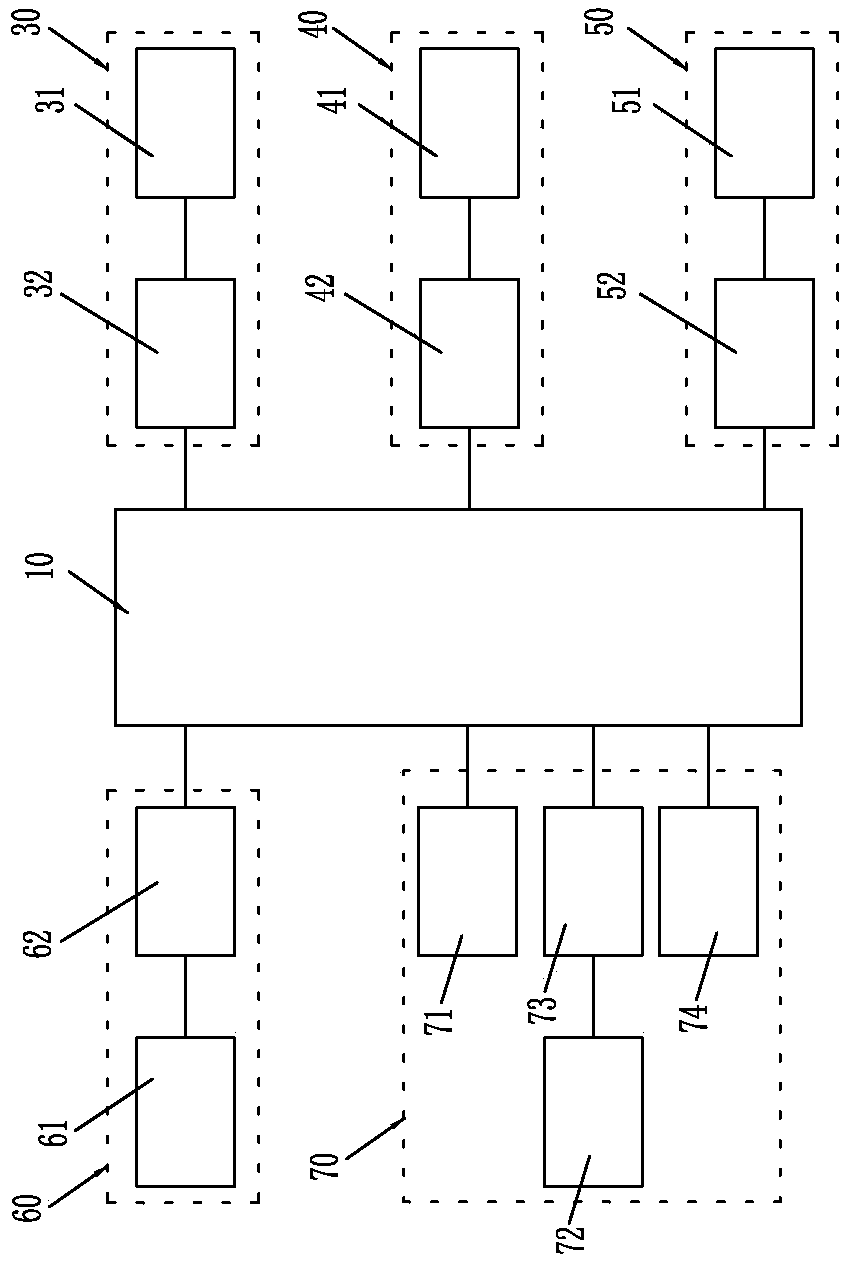

[0040] Please refer to Figure 1 to Figure 3 As shown, it has shown the specific structure of the embodiment of the present invention, the automatic wire management device for the PIN pin of the filter coil includes a main controller 10, a wire management bracket assembly, a coil placement mechanism 30, and a PIN pin wire Straightening mechanism 40, PIN foot wire cutting mechanism 50, cable management bracket turning mechanism 60 and magnetic suction positioning and pushing mechanism 70; wherein:

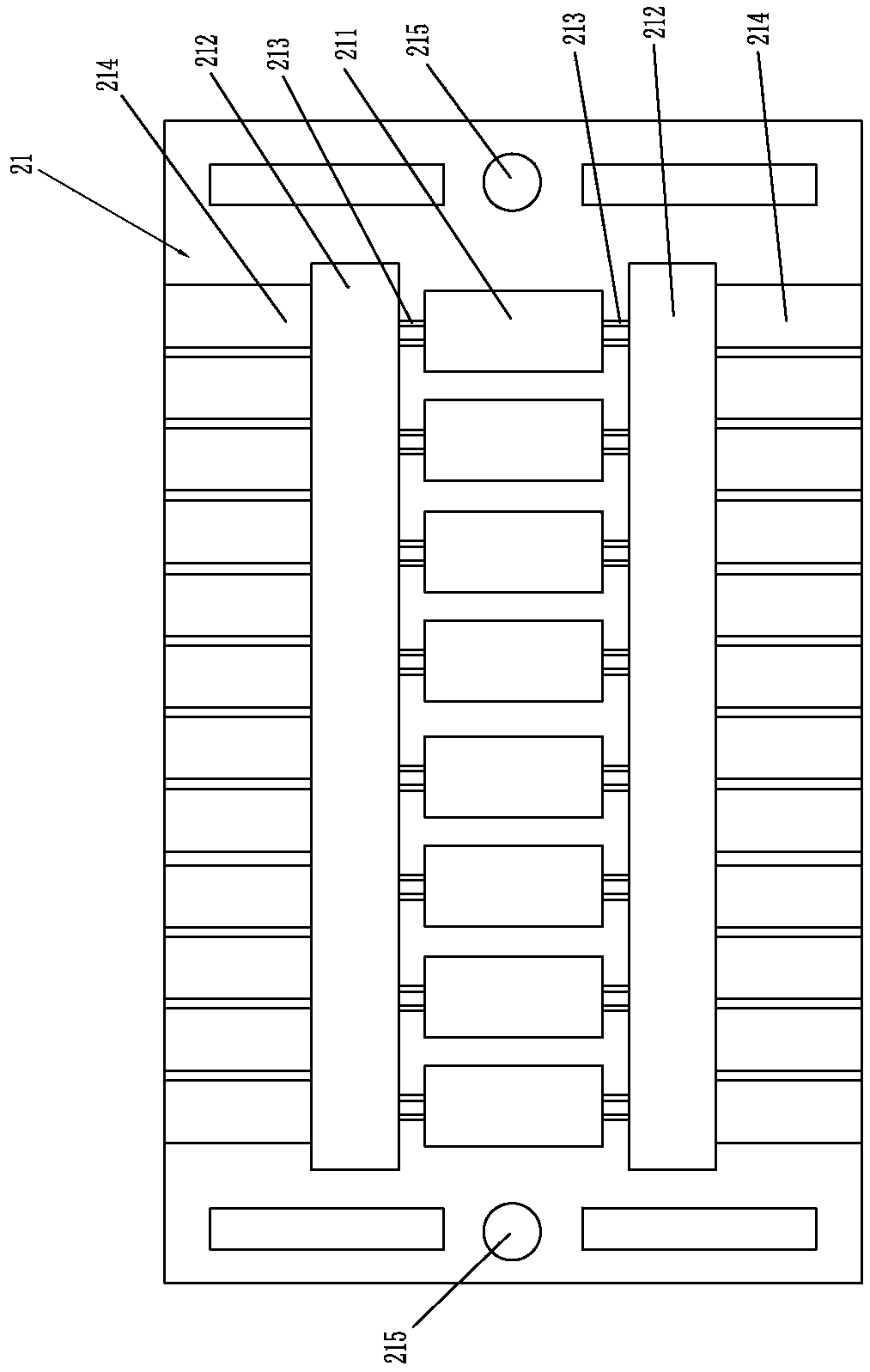

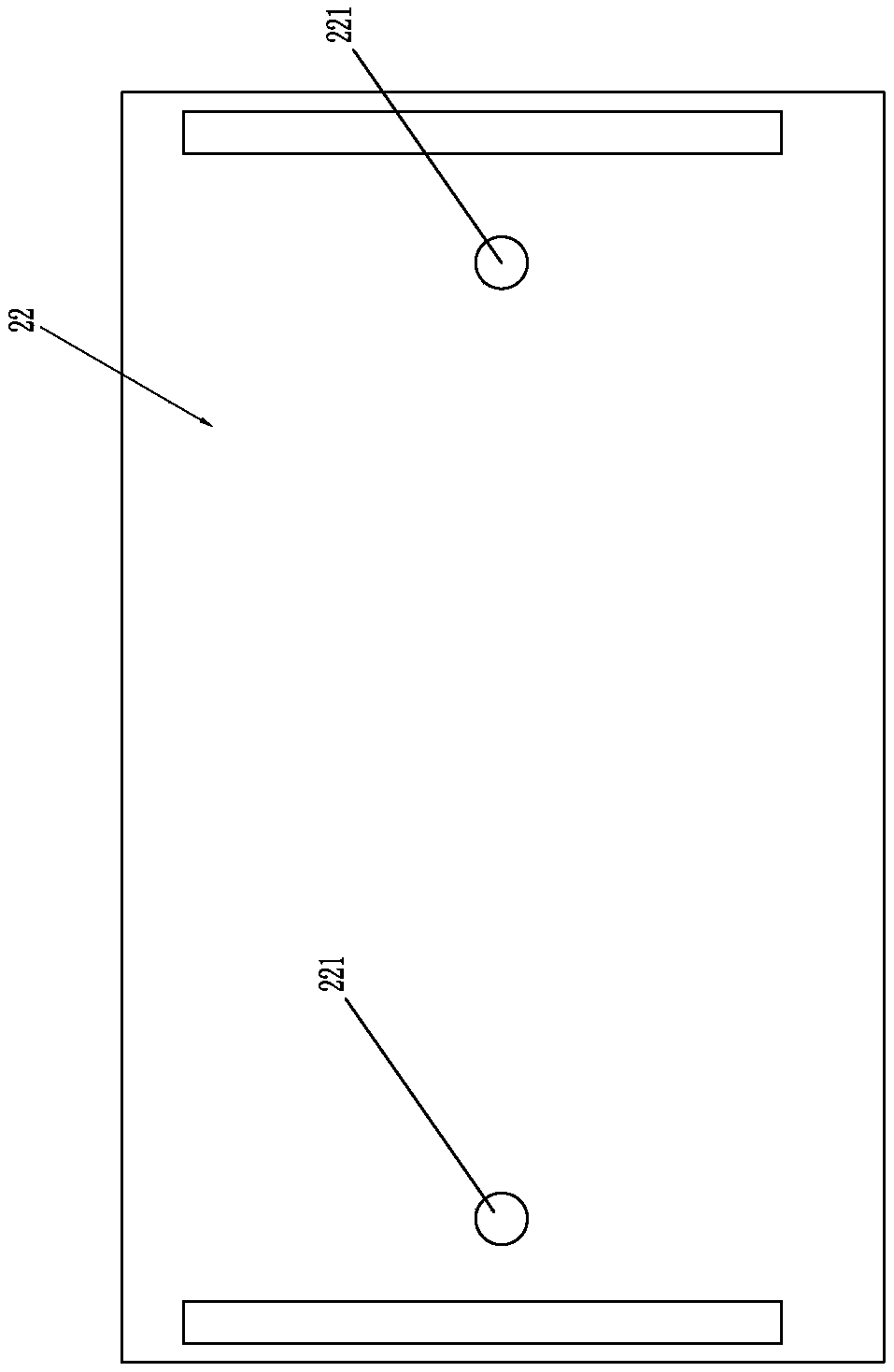

[0041] The wire management bracket assembly includes a wire management main frame 21 and a wire management cover 22. The upper side of the wire management main frame 21 is recessed with a row of coil placement grooves 211, two give way slots 212, and two rows of the second row. A wire slot 213 and two rows of second wire slots 214; two step-off slots 212 are connected to the upper side and the lower side of the main frame 21; Coil placement grooves 211, a row of coil placement groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com