Chip detection rewriting device and system

A chip detection and equipment technology, applied in printing, instruments, computer parts and other directions, can solve problems such as non-compliance with the basic principles of standardized production of enterprises, insufficient coordination and uniformity of equipment software management, and inconvenient software management personnel. Increase the short-circuit detection function, high utilization rate of resource integration, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

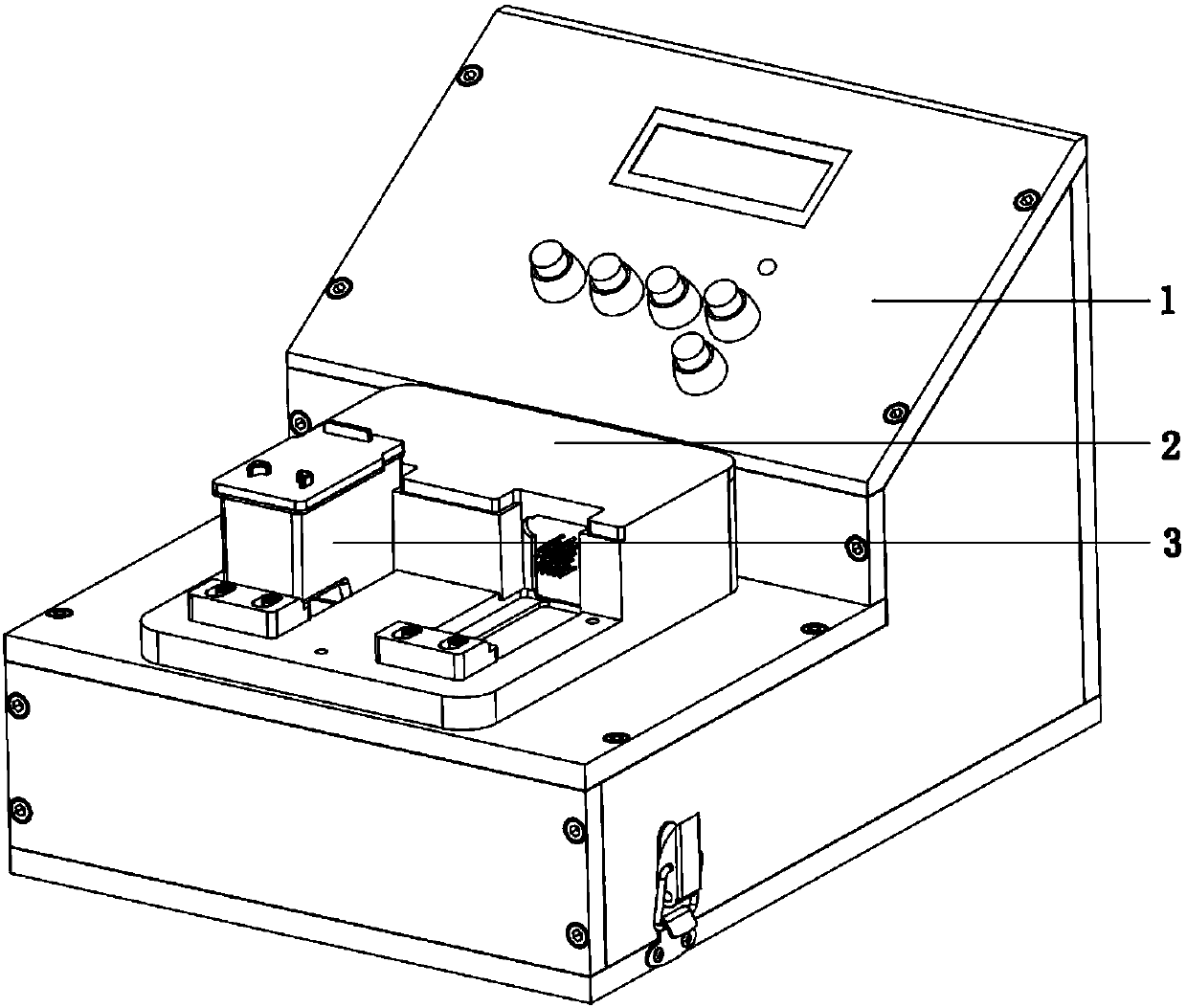

[0045] A chip detection and rewriting system, such as figure 1 As shown, it includes a chip detection and rewriting device 1 and an ink cartridge holder 2 for fixing the ink cartridge. The ink cartridge holder 2 is provided with an interface unit, and the interface unit communicates with the serial port unit of the chip detection and rewriting device 1. The ink cartridge holder 2 is movably installed on the chip detection and rewriting device. On the device chassis of device 1.

[0046] Preferably, the ink cartridge holder 2 and the chip detection and rewriting device 1 are provided with mutually attracting magnetic elements, and the ink cartridge hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com