Fluorescent ceramic material, preparation method thereof and low-color-temperature white light LED

A fluorescent ceramic, white light technology, applied in luminescent materials, chemical instruments and methods, sustainable architecture, etc., can solve the problems of uneven light emission color, reduced light efficiency, aging of phosphors, etc., and achieve excellent mechanical and mechanical properties, The effect of improving the color rendering index and prolonging the life of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

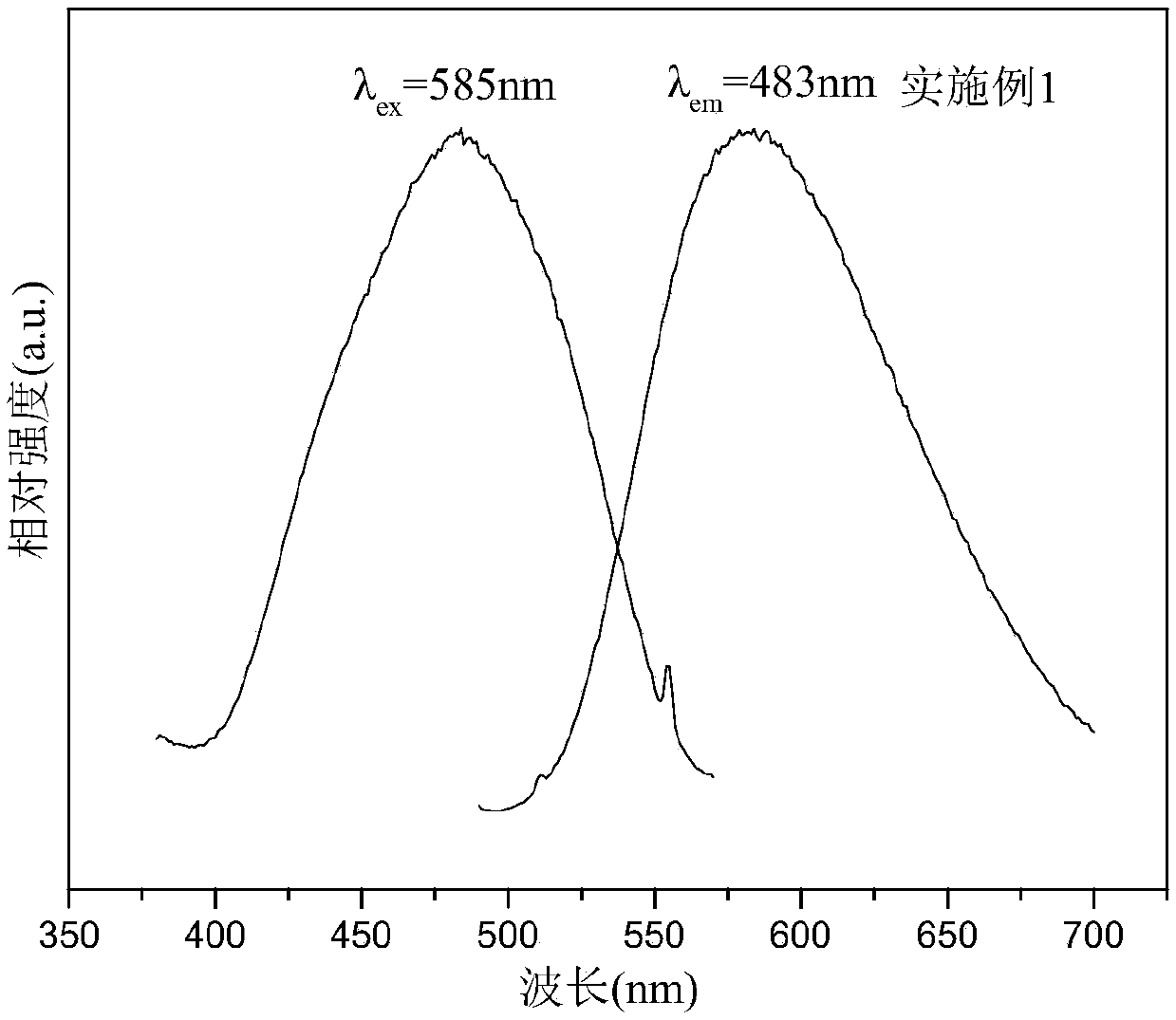

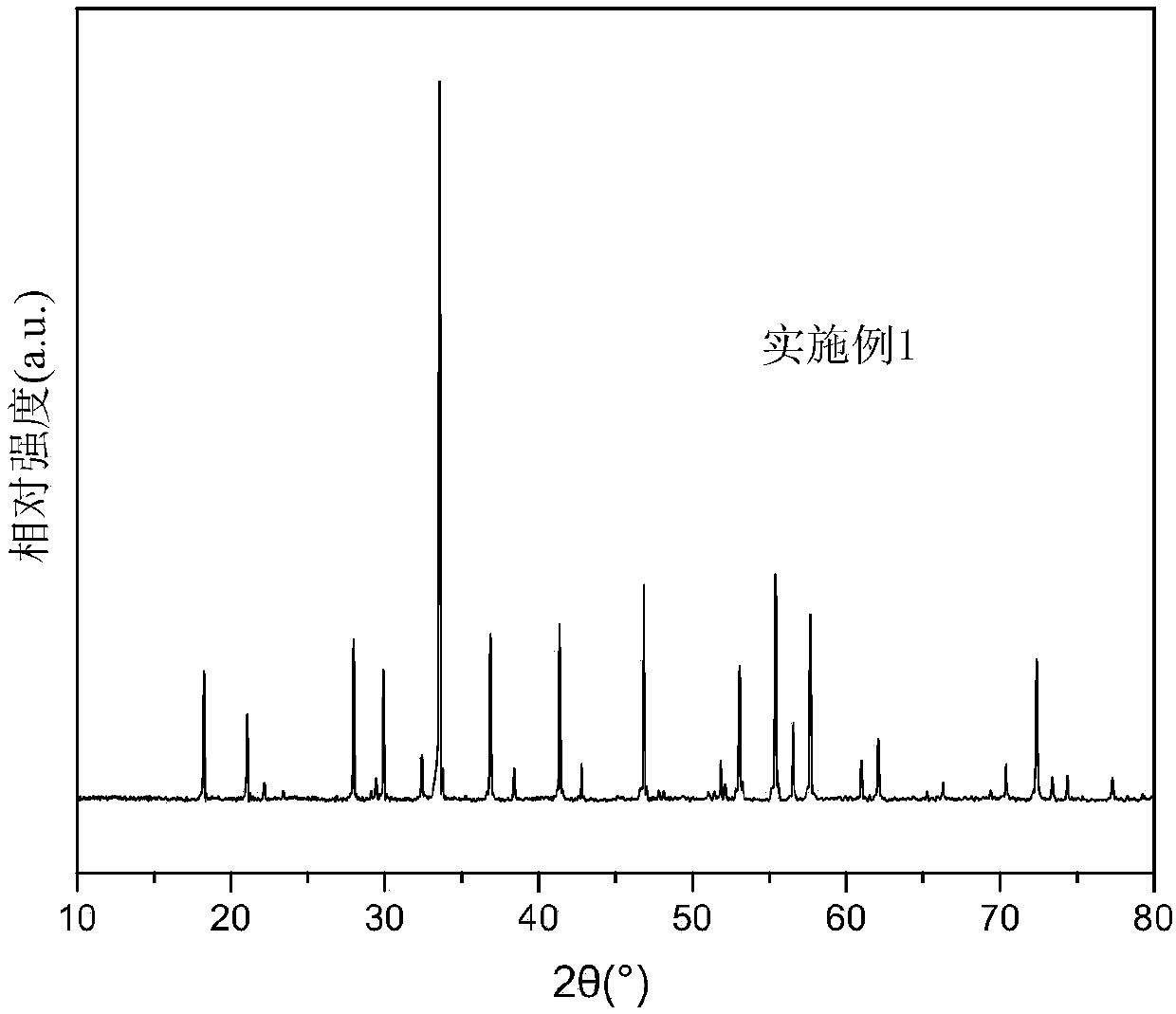

Embodiment 1

[0029] Fluorescent ceramic sheet (Lu 1.99 Ce 0.01 Ca)(Mg 2 Si 3 )O 12 The preparation method is as follows:

[0030] (1) Weigh Lu by stoichiometric ratio 2 o 3 : 3.9594g, CeO 2 : 0.0172g, CaCO 3 : 1.0087g, MgO: 0.8061g, SiO 2 : 1.8025g; Add agate balls to the grinding tank, and use absolute ethanol as the grinding medium to grind and mix until the average particle size of the powder is less than 1 μm;

[0031] (2) The obtained slurry is dried and sieved, and the sieved powder is kept at 1000°C in the air for 2 hours to remove the organic matter in the powder, and the CaCO 3 Fully decompose; after sieving the obtained powder, apply a pressure of 10Mpa equiaxially and unidirectionally to keep it for 2min, dry press molding, press it into a green body in a cold isostatic pressing equipment, the pressure is 200MPa, and the holding time is 2min;

[0032] (3) The obtained ceramic green body is sintered in a vacuum furnace at a heating rate of 1°C / min, kept at 1200°C for 4 ...

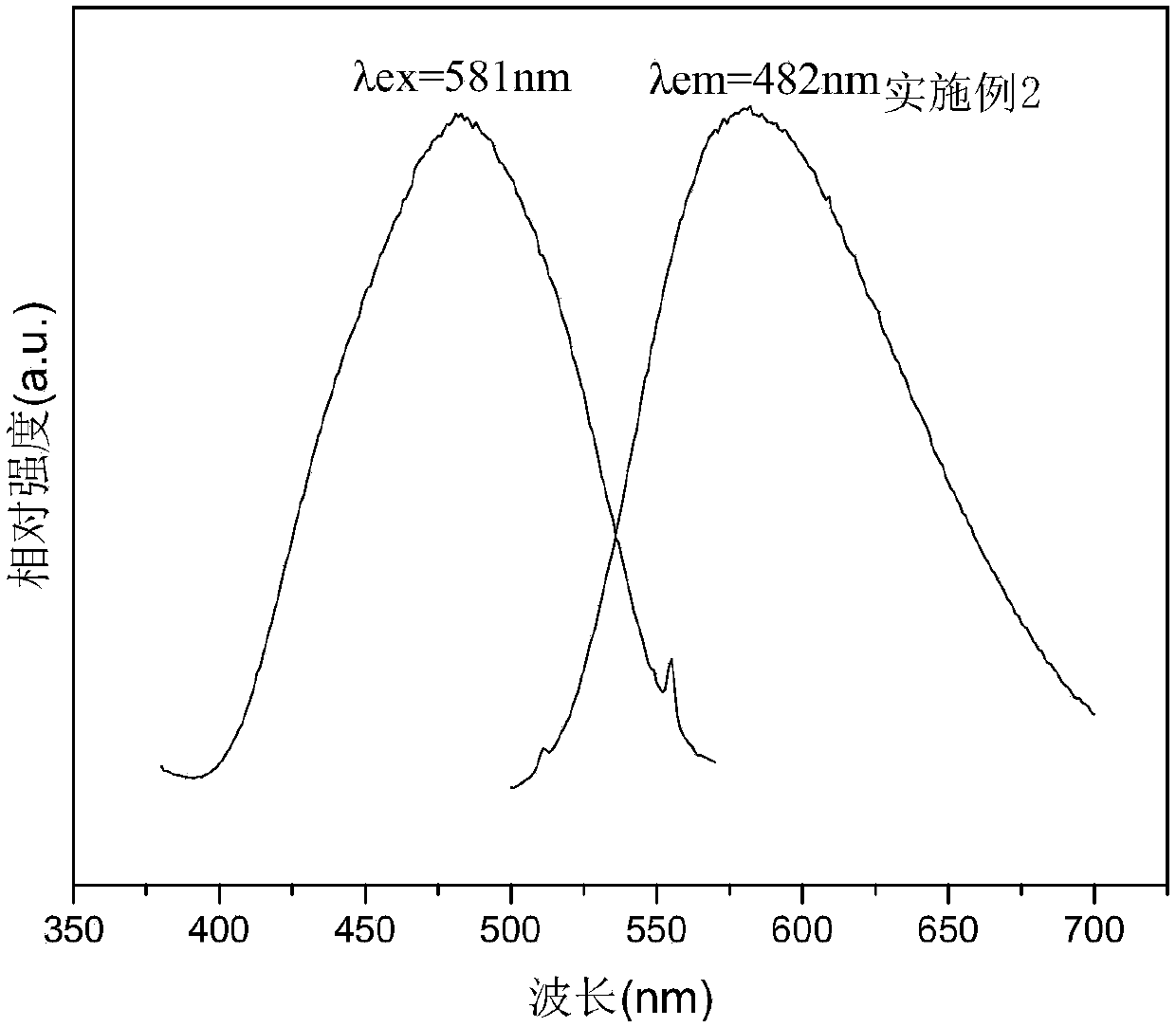

Embodiment 2

[0038] Fluorescent ceramic sheet (Lu 1.99 Ce 0.01 Ca 0.9 Ba 0.1 )(Mg 2 Si 3 )O 12 The preparation method is as follows:

[0039] (1) Weigh Lu by stoichiometric ratio 2 o 3 : 3.9594g, CeO 2 : 0.0172g, CaCO 3 : 0.9074g, BaCO 3 : 0.0164g, MgO: 0.8061g, SiO 2 : 1.8025g. Use a grinding tank to add agate balls, and use absolute ethanol as the grinding medium for grinding and mixing until the average particle size of the powder is less than 1 μm;

[0040] (2) The obtained slurry is dried and sieved, and the sieved powder is kept at 1000°C in the air for 2 hours to remove the organic matter in the powder, and the CaCO 3 Fully decompose; after sieving the obtained powder, apply a pressure of 10Mpa equiaxially and unidirectionally to keep it for 2min, dry press molding, press it into a green body in a cold isostatic pressing equipment, the pressure is 200MPa, and the holding time is 2min;

[0041] (3) The obtained ceramic green body was sintered in a vacuum furnace at a he...

Embodiment 3

[0047] Fluorescent ceramic sheet (Lu 1.99 Ce 0.005 PR 0.005 Ca)(Mg 2 Si 3 )O 12 The preparation method is as follows:

[0048] (1) Weigh Lu by stoichiometric ratio 2 o 3 : 3.9594g, CeO 2 : 0.0086, Pr 6 o 11 : 0.0085g, CaCO 3 : 1.0087g, MgO: 0.8061g, SiO 2 : 1.8025g. Use a grinding tank to add agate balls, and use absolute ethanol as the grinding medium for grinding and mixing until the average particle size of the powder is less than 1 μm;

[0049] (2) Dry and sieve the obtained slurry, keep the sieved powder at 900°C for 2 hours in the air, remove the organic matter in the powder, and let the CaCO 3 Fully decompose; after sieving the obtained powder, apply a pressure of 10Mpa equiaxially and unidirectionally to keep it for 2min, dry press molding, press it into a green body in a cold isostatic pressing equipment, the pressure is 200MPa, and the holding time is 2min;

[0050] (3) The obtained ceramic green body is sintered in a vacuum furnace at a heating rate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap