Construction method of pre assembling of water guide mechanism with participation of runner

A construction method and water guiding mechanism technology, which is applied in the field of pre-installation of water guiding mechanism with runners, can solve problems such as complicated procedures and long construction period, and achieve the effects of optimizing construction procedures, improving construction efficiency, and improving installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

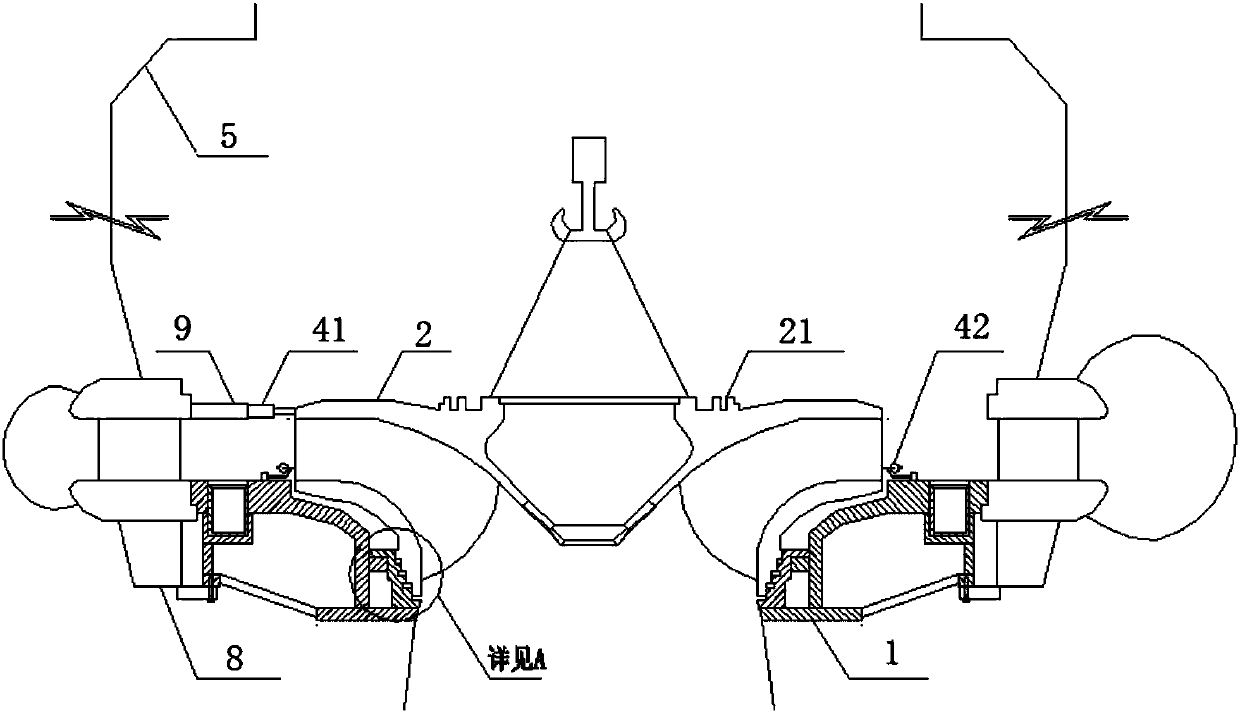

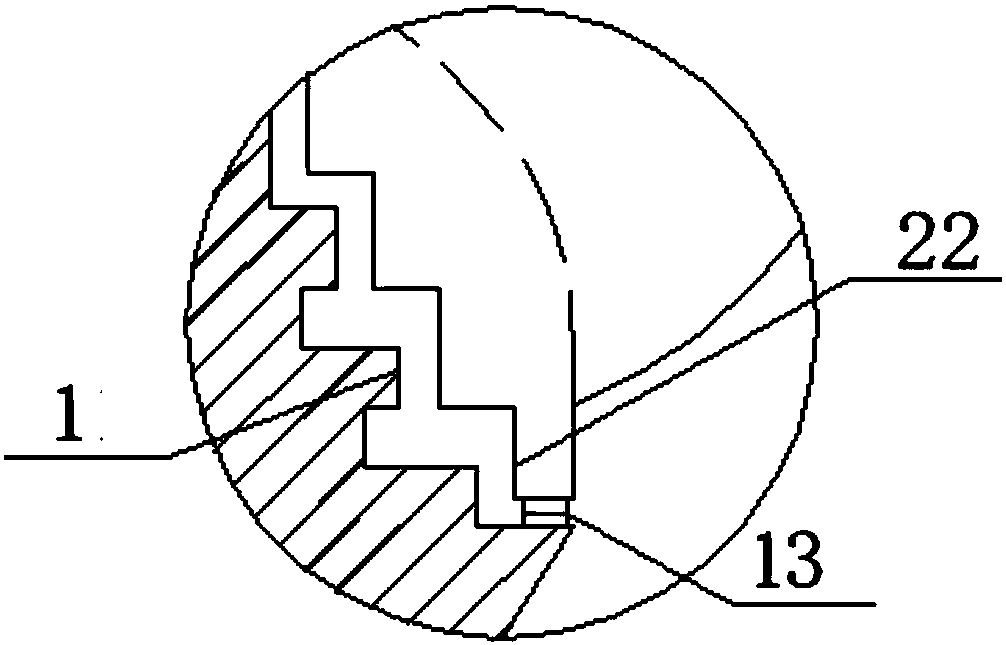

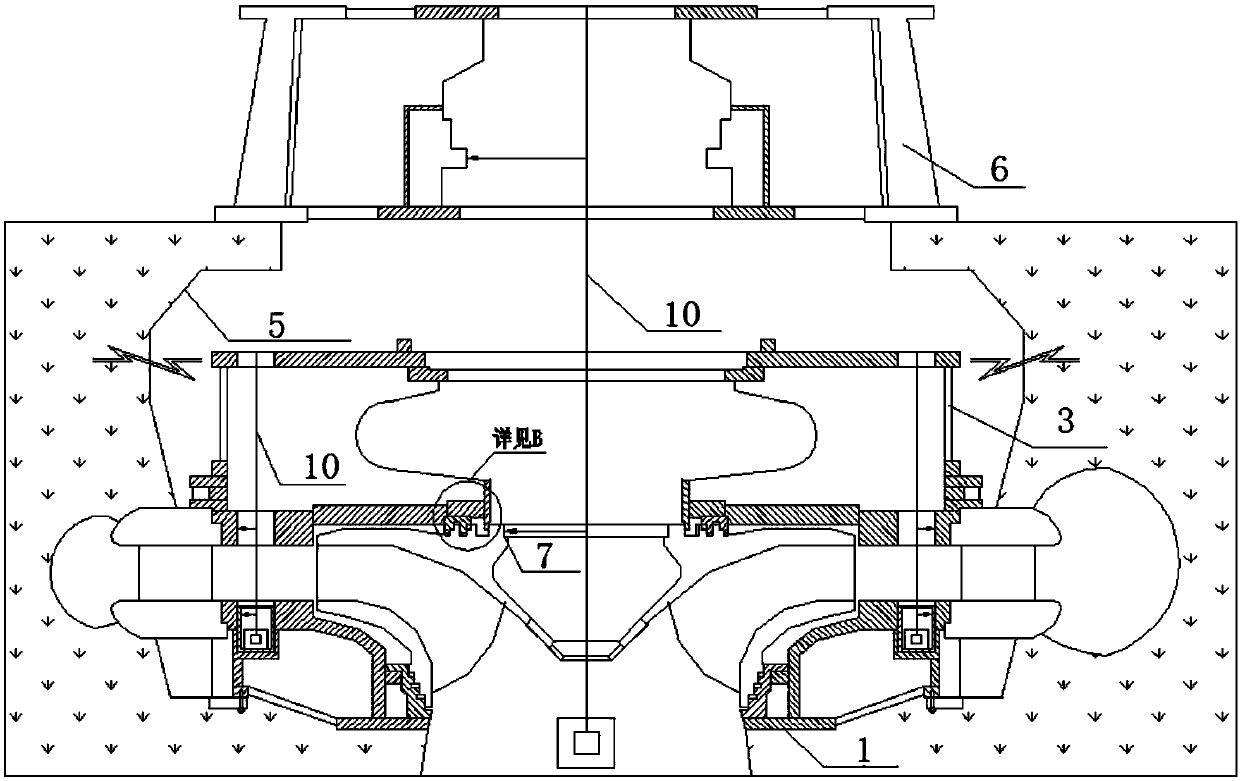

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. A construction method for the pre-installation of a runner participating in a water guiding mechanism. Place the wedge plate 13 on the lower plane of the anti-leakage ring 11, and then hoist the pre-assembled runner 2 into the machine pit and place it on the wedge plate 13; Step 2: Adjust the center of the runner 2 by pushing the method, and fix it with the wedge plate 13 The center position of the runner 2; Step 3: Hoist the top cover 3 into the machine pit for assembly. After the assembly is completed, hang the top cover 3 as a whole, hoist it into the movable guide vanes participating in pre-installation, and then put down the top cover 3 for pre-installation ; Step 4: Adjust the center of the top cover 3 by measuring the gap between the leak-proof ring 11 on the top cover in the symmetrical direction and the labyrinth ring 21 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com