Construction method for towing underwater pipeline on sea

A pipeline and towing technology, applied in the field of underwater towing construction methods for underwater pipelines, can solve problems such as difficulty in meeting time limit requirements, difficulty in land transportation due to site conditions, and worrying about the quality of underwater pipelines, so as to achieve safety hazards and savings in unmanned operation. Time and cost, the effect of avoiding secondary assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

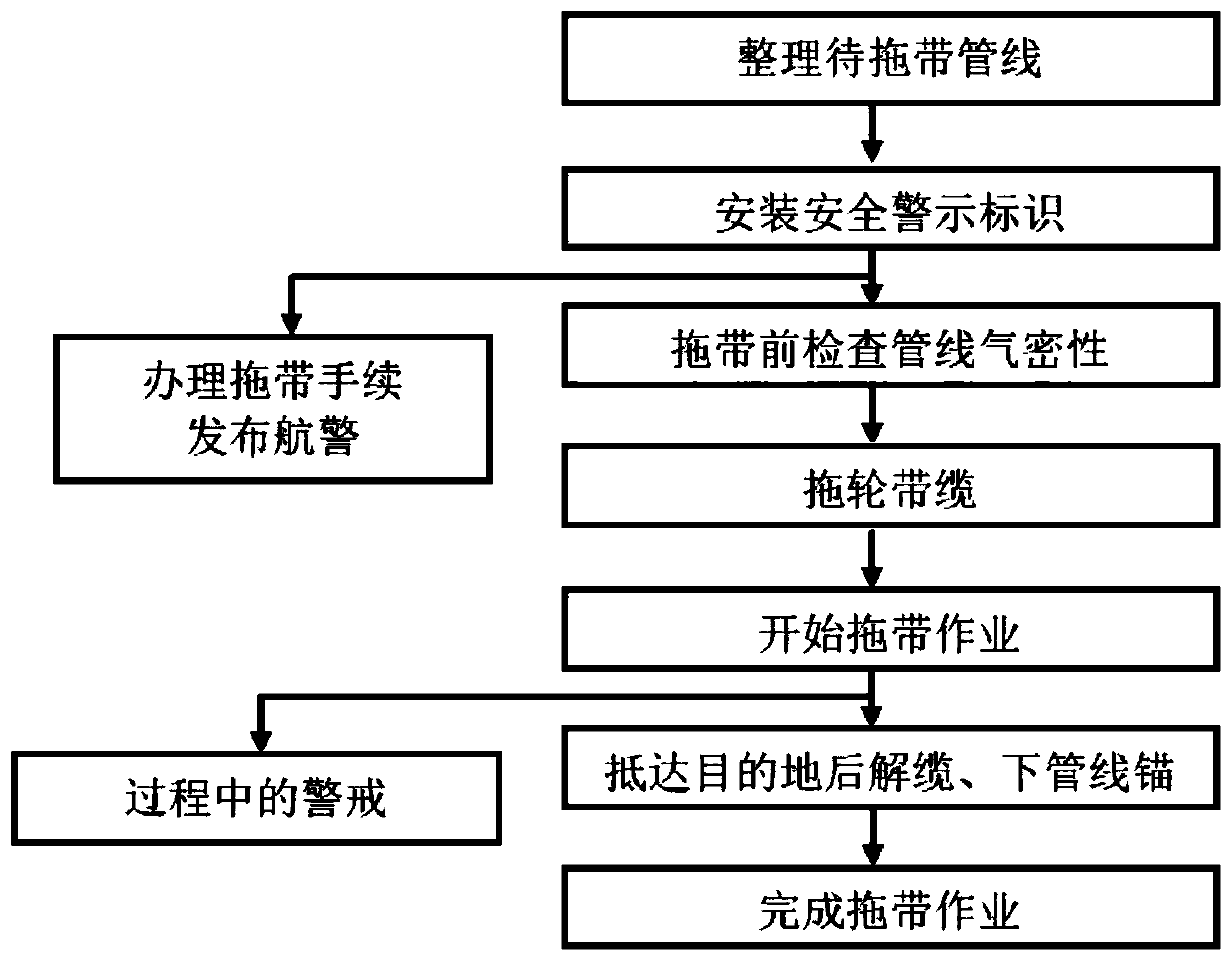

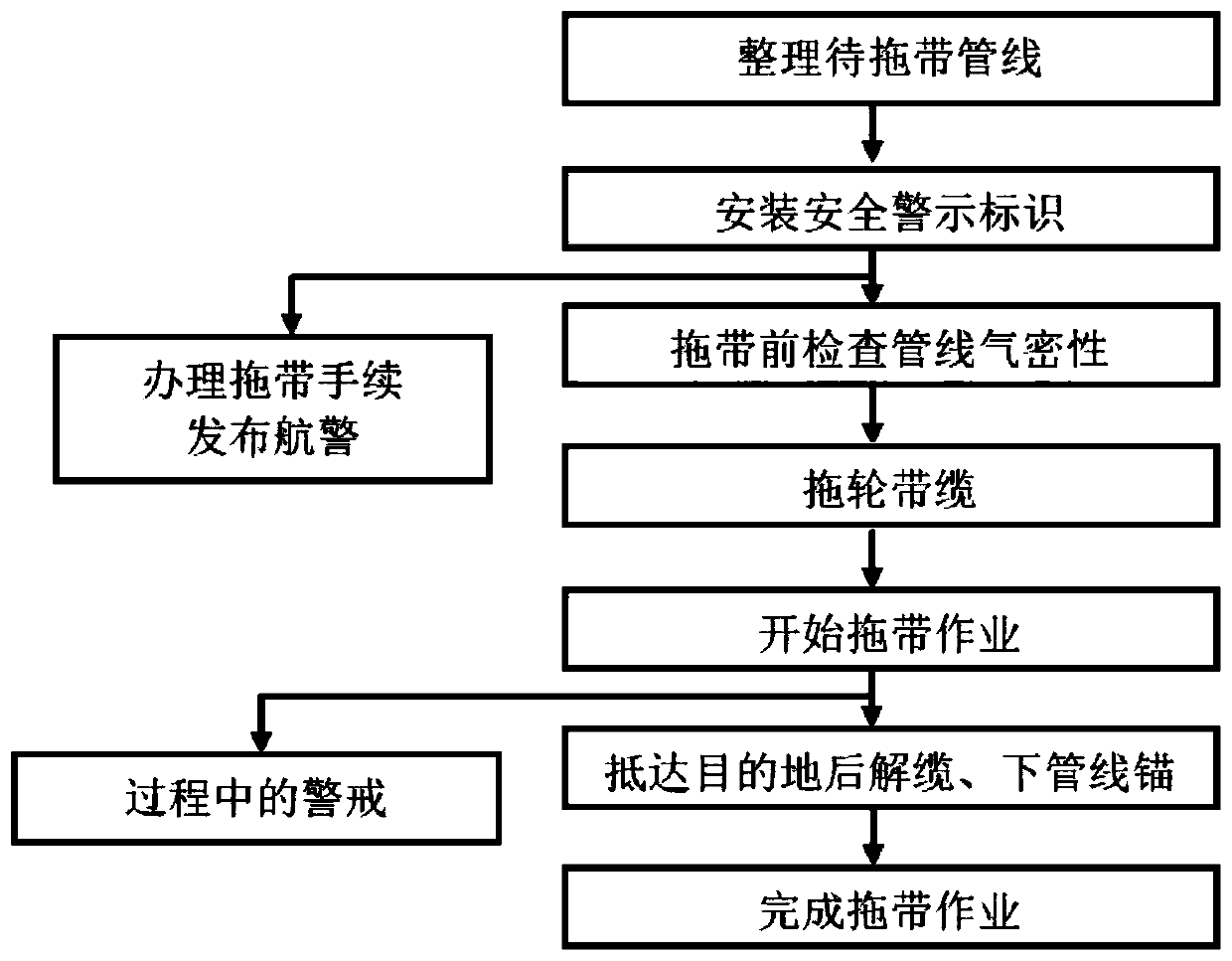

[0012] See figure 1 , the offshore towing construction method of the underwater pipeline of the present invention comprises the following steps,

[0013] (1) Arrange the pipeline to be towed so that the underwater pipeline floats on the water surface under the action of its own buoyancy;

[0014] (2) Install safety warning signs on the pipeline; install multiple flashing lights on the pipeline to warn passing ships during night towing and ensure towing safety.

[0015] (3) Check the airtightness of the pipeline before towing;

[0016] Before towing, the pipeline to be towed should be stored on the water surface, and its air tightness should be observed for no less than 24 hours. After the pipeline is stabilized on the water, relevant marks can be set on the waterline of the pipeline for easy observation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com