A friction stir welding device and method for the longitudinal seam of the bottom circular ring of a large-diameter launch vehicle

A friction stir welding and launch vehicle technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of product scrap, padding of the stirring head, difficulty, etc., to improve manufacturing accuracy and efficiency, guarantee Product manufacturing efficiency, the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Taking the heavy-duty carrier rocket whose tank diameter reaches Φ7.5m level and whose bottom ring is composed of 12 melon petals as an example, the device and welding method of the present invention are introduced:

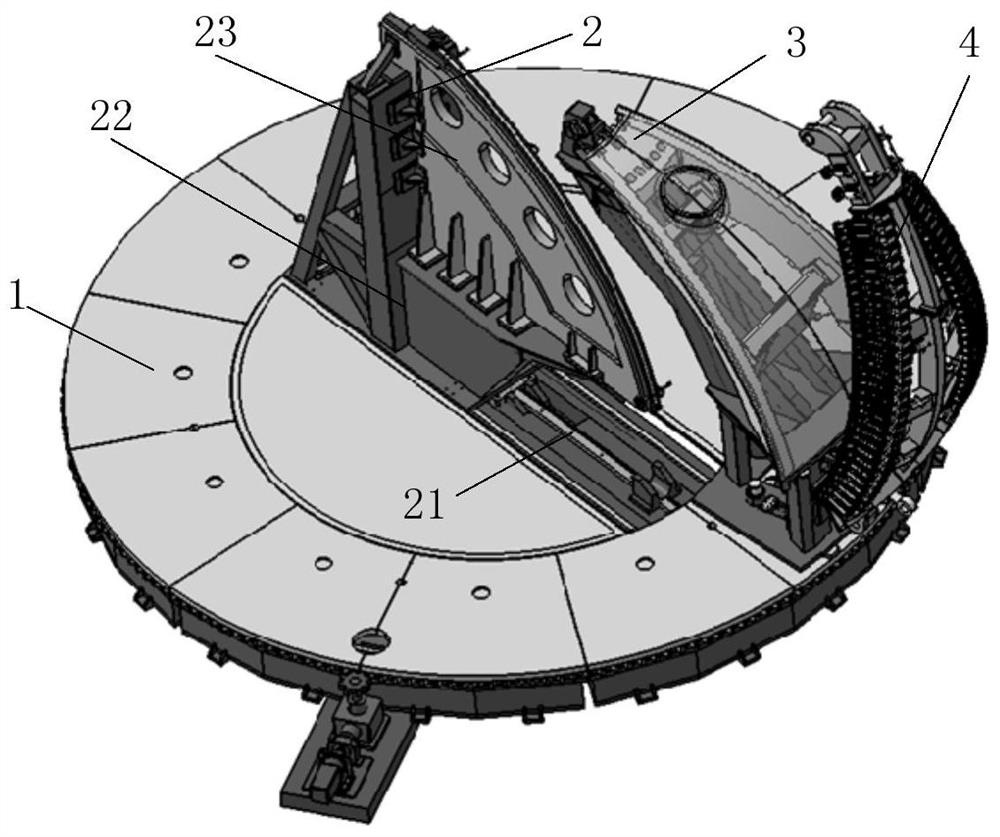

[0037] Such as figure 1 As shown, the present invention includes a turntable 1, a moving pad device 2, 12 split membrane tires 3 and 12 external pressure systems 4.

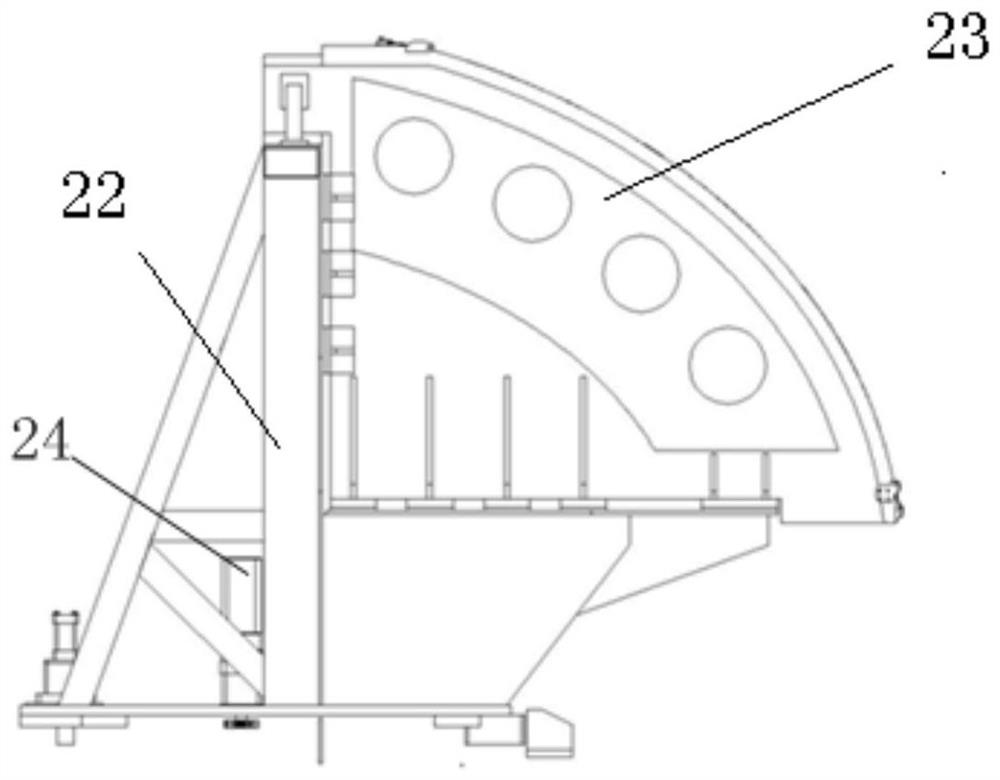

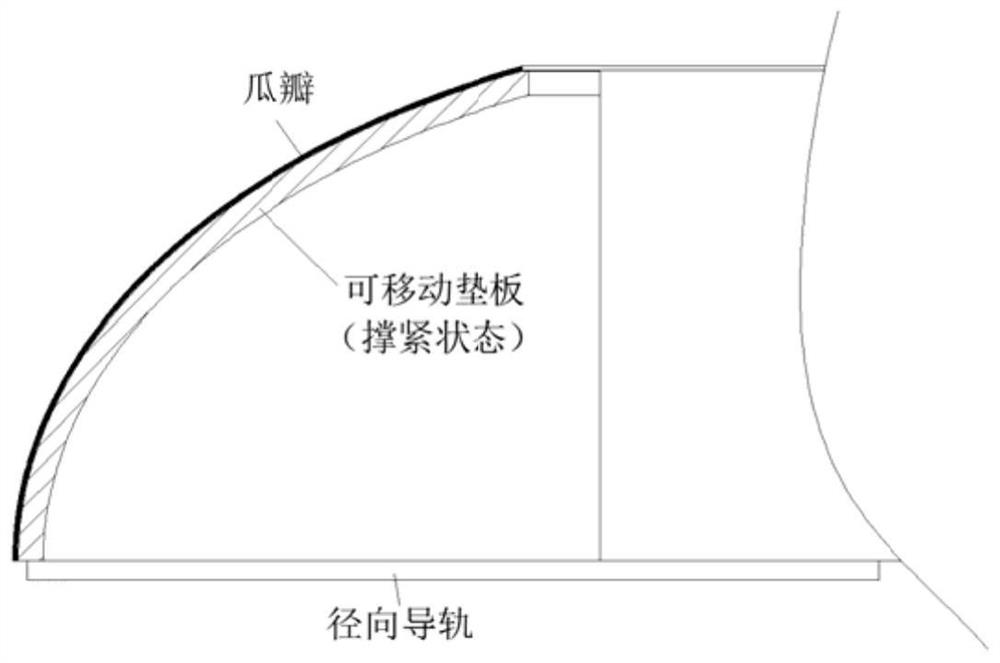

[0038] Such as figure 1 and figure 2 As shown, the mobile backing device 2 includes two linear guide rails 21, a support frame 22, a motor 24 and a backing plate 23; the two linear guide rails 21 are symmetrically installed on the inner circle of the turntable 1 along the center line of the turntable 1, and the support frame 22 is installed on the inner circle of the turntable 1. On the sliders of the two linear guide rails 21, the backing plate 23 is installed on the support frame 22, and the motor 24 is connected with the support frame 22 through a screw to drive the support frame 22 alo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com