Load-bearing pier capable of monitoring weights of sub-segments and total segment real-timely and measurement operation method thereof

A real-time monitoring and weight technology, applied in the field of load-bearing piers, can solve problems such as inability to obtain accurate weight, segmental safety issues, segmental overweight and overturning, etc., and achieve the effects of shortening segmental construction time, improving efficiency, and reducing rework problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereby.

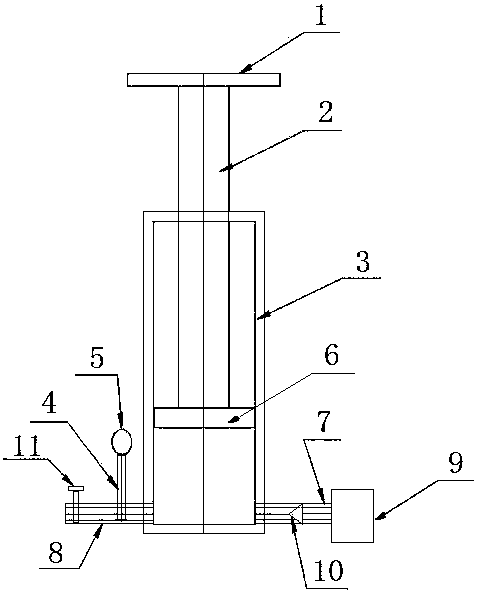

[0018] Such as figure 1 As shown, the present embodiment can monitor the load-bearing pier of the total section weight in real time. The pier includes a load-bearing bracket 1, a piston rod 2, an oil cylinder 3, a pressure sensor 4, a pressure sensor display 5, and one end of the piston rod 2 The piston 6 is connected to the oil cylinder 3, and the other end of the piston rod 2 is connected to the load-bearing bracket 1. An oil inlet pipe 7 and an oil outlet pipe 8 are arranged at the bottom of the oil cylinder 3, and the oil inlet pipe 7 and the oil outlet pipe 8 are connected to the oil cylinder. 3 are connected internally, the oil inlet end of the oil inlet pipe 7 is connected with the power source 9, a check valve 10 is arranged on the oil inlet pipe 7, a pressure sensor 4 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com