Display panel and manufacturing method thereof

A technology of display panel and manufacturing method, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as limiting display quality, large cathode impedance, reducing current conduction capability, etc., so as to improve display quality, reduce Impedance, the effect of improving electron injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The word "embodiment" as used in this specification means an example, instance or illustration. Furthermore, as used in this specification and the appended claims, the article "a" or "an" may generally be construed as "one or more" unless specified otherwise or clear from the context in the singular.

[0025] The display panel of the present invention is an OLED (Organic Light Emitting Diode, organic light emitting diode display panel) or the like.

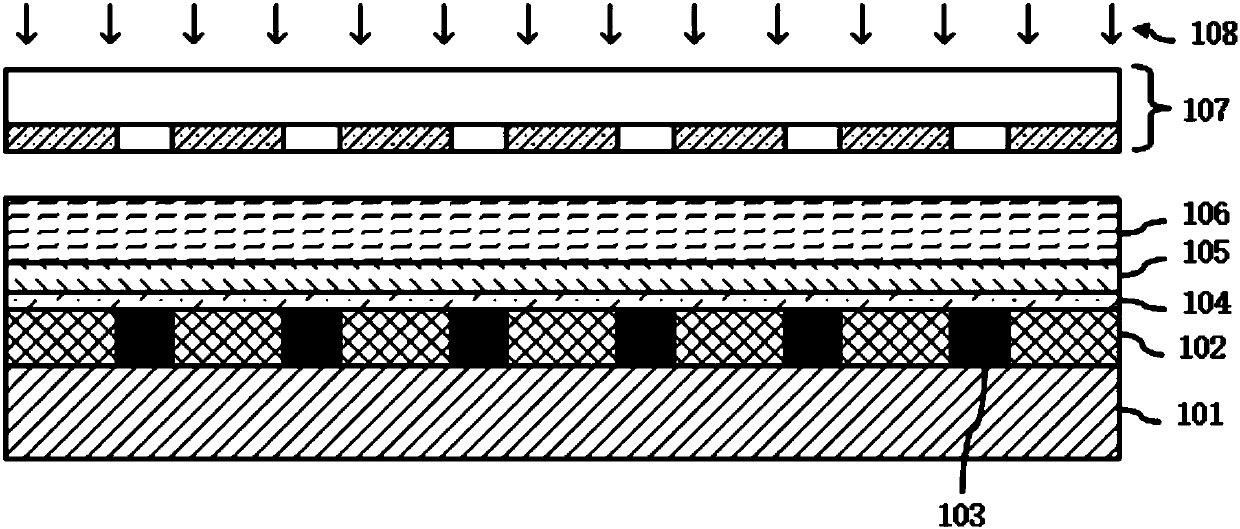

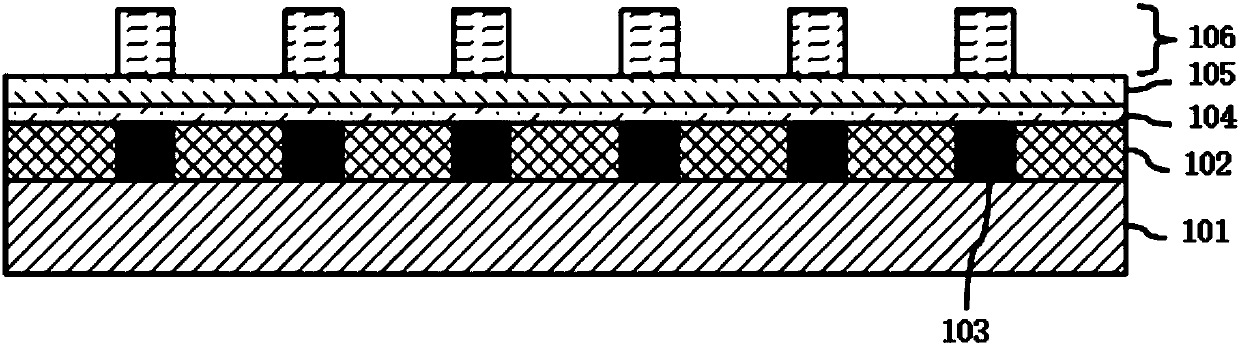

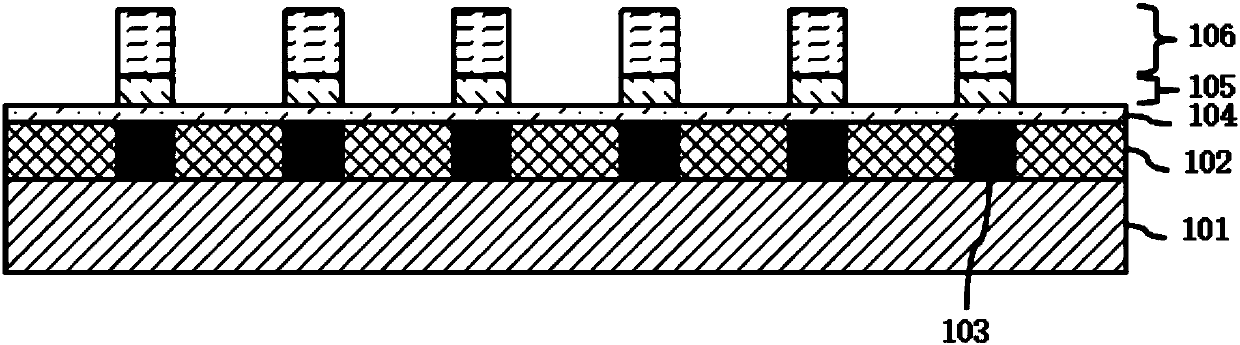

[0026] refer to Figure 5 , Figure 5 It is a schematic diagram of a partial section of the display panel of the present invention.

[0027] The display panel of the present invention includes a thin film transistor array substrate 101 , an organic light emitting functional layer, a pixel defining layer, a cathode layer, and a transparent encapsulation layer 501 .

[0028] The thin film transistor array substrate 101 includes a thin film transistor switch array and an anode array, the thin film transistor switches in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com