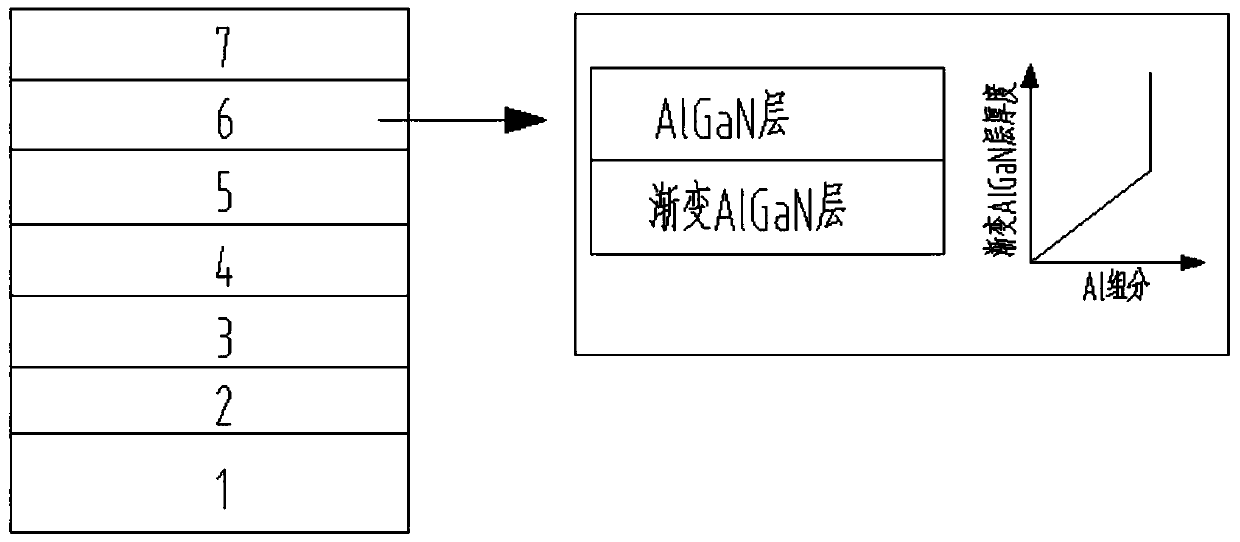

GaN-based ultraviolet LED epitaxial structure and carrier transport improvement method thereof

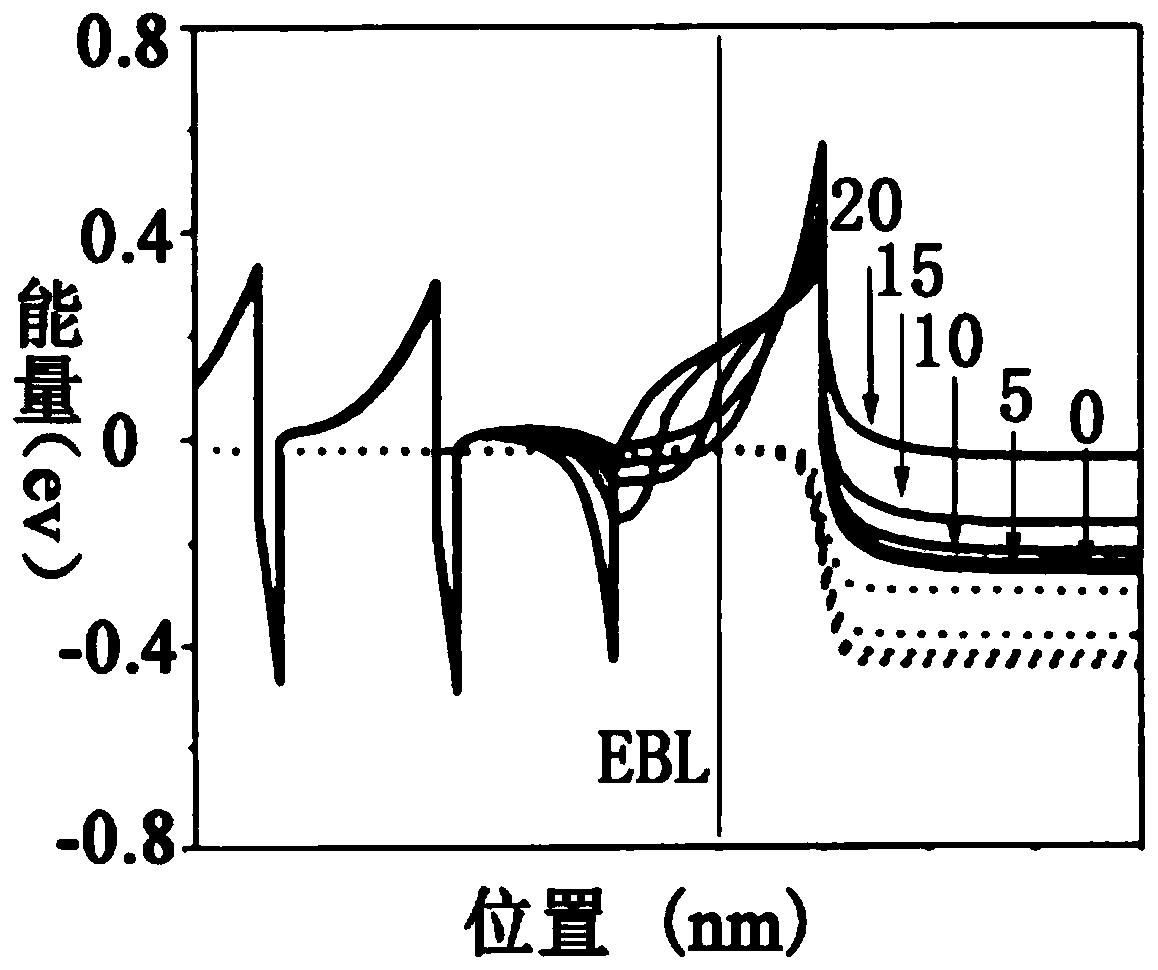

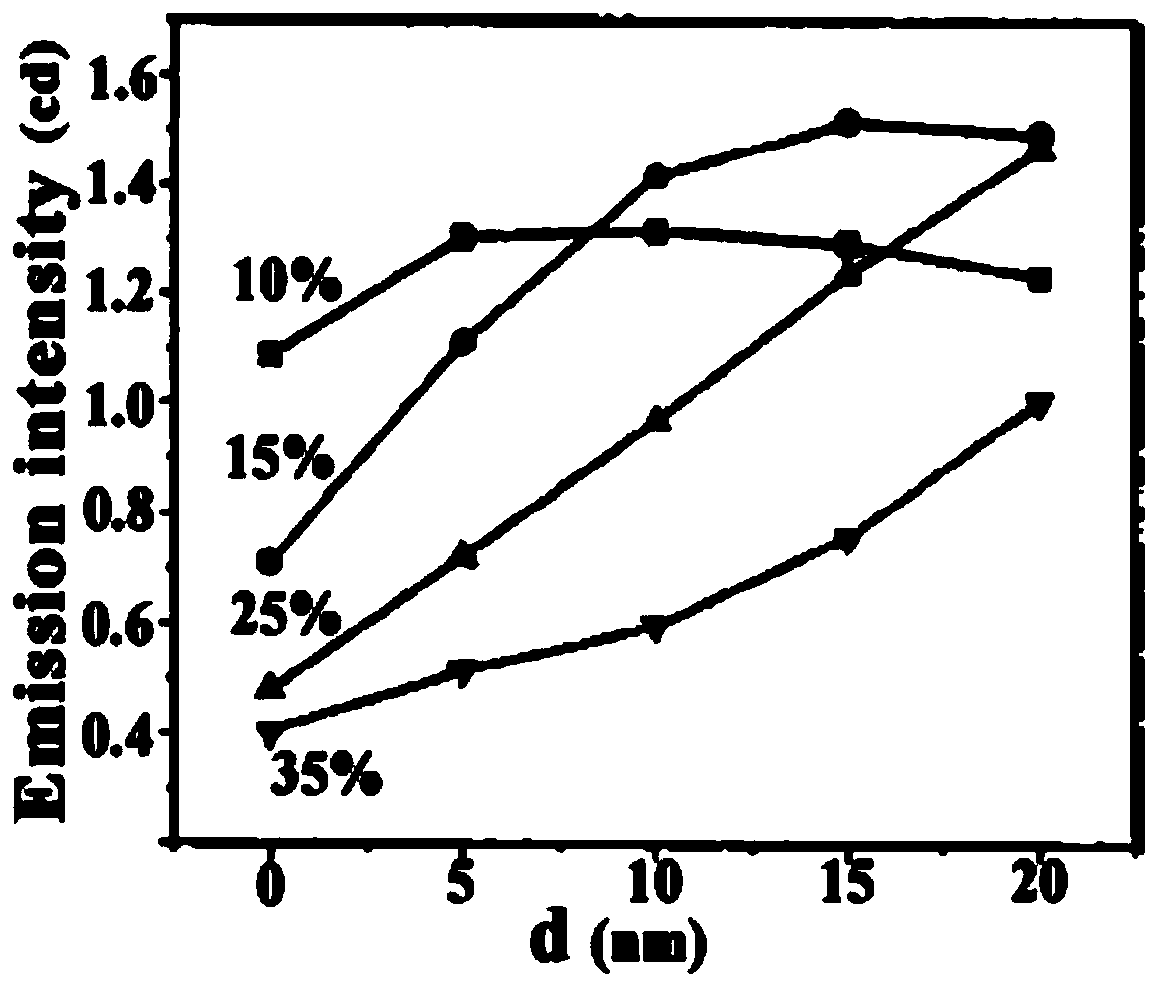

An epitaxial structure and carrier technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of EBL application limitations, etc., to reduce electron overflow, improve hole injection efficiency, increase light intensity and light output power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This embodiment provides a method for improving carrier transport in a GaN-based ultraviolet LED, including the following steps:

[0066] (1-1) At 1100°C, H 2 Under the atmosphere, treat the sapphire substrate at high temperature for 10 minutes, completely remove the oxides and impurities on the surface of the substrate, and the pressure is 200mbar;

[0067] (1-2) Gradually cool down to 600°C and turn on NH 3 , nitriding the sapphire substrate 1 for 5 minutes at a pressure of 500 mbar;

[0068] (1-3) Keep the temperature constant, turn on TMAl, and grow a low-temperature AlN buffer layer on the sapphire substrate 1 with a thickness of 30nm and a pressure of 500mbar;

[0069] (1-4) Raise the temperature to 1050° C., grow a 1 μm U-GaN layer 3 on the low-temperature AlN buffer layer, the pressure is 500 mbar, and the molar ratio of V / III during the growth process is 500;

[0070] Wherein, Ⅴ represents an element of the fifth main group, and III represents an element of ...

Embodiment 2

[0081] This embodiment provides a method for improving carrier transport in a GaN-based ultraviolet LED, including the following steps:

[0082] (2-1) At 1200°C, H 2 Under the atmosphere, treat the sapphire substrate at high temperature for 5 minutes to completely remove the oxides and impurities on the surface of the substrate, and the pressure is 500mbar;

[0083] (2-2) Gradually cool down to 580°C and turn on NH 3 , nitriding the sapphire substrate for 5 minutes at a pressure of 400 mbar;

[0084] (2-3) Keep the temperature constant, turn on TMAl, and grow a low-temperature AlN buffer layer on the sapphire substrate with a thickness of 40nm and a pressure of 600mbar;

[0085] (2-4) Raise the temperature to 1055°C, grow a 1μm U-GaN layer on the low-temperature GaN buffer layer, the pressure is 600mbar, and the molar ratio of V / III during the growth process is 600;

[0086] Wherein, Ⅴ represents an element of the fifth main group, and III represents an element of the third...

Embodiment 3

[0095] This embodiment provides a method for improving carrier transport in a GaN-based ultraviolet LED, including the following steps:

[0096] (3-1) At 1150°C, H 2 Under the atmosphere, treat the sapphire substrate at high temperature for 8 minutes, completely remove the oxides and impurities on the surface of the substrate, and the pressure is 400mbar;

[0097] (3-2) Gradually cool down to 580°C and turn on NH 3 , nitriding the sapphire substrate for 4 minutes at a pressure of 300 mbar;

[0098] (3-3) Keep the temperature constant, turn on TMAl, and grow a low-temperature AlN buffer layer on the sapphire substrate with a thickness of 45nm and a pressure of 700mbar;

[0099] (3-4) Raise the temperature to 1060°C, grow a 1μm U-GaN layer on the low-temperature GaN buffer layer, the pressure is 700mbar, and the molar ratio of V / III during the growth process is 900;

[0100] Wherein, Ⅴ represents an element of the fifth main group, and III represents an element of the third m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com