Circuit board air-cooled heat radiation device

A heat dissipation device and circuit board technology, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of large installation space of the adjustment device, unsuitable places with compact structures, and small ventilation volume. , to improve the heat dissipation effect, simplify the heat dissipation layout, and facilitate the effect of centralized air cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

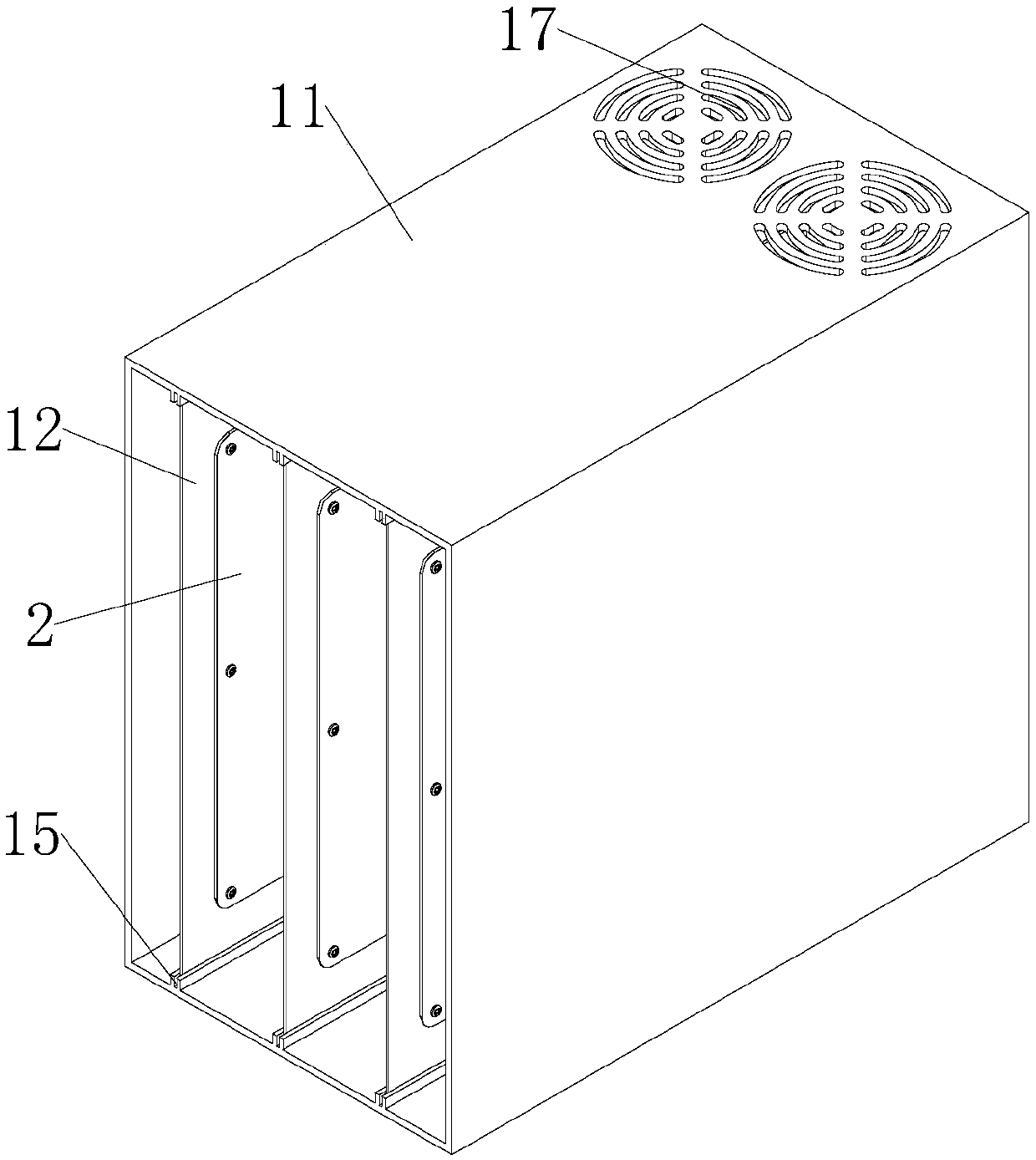

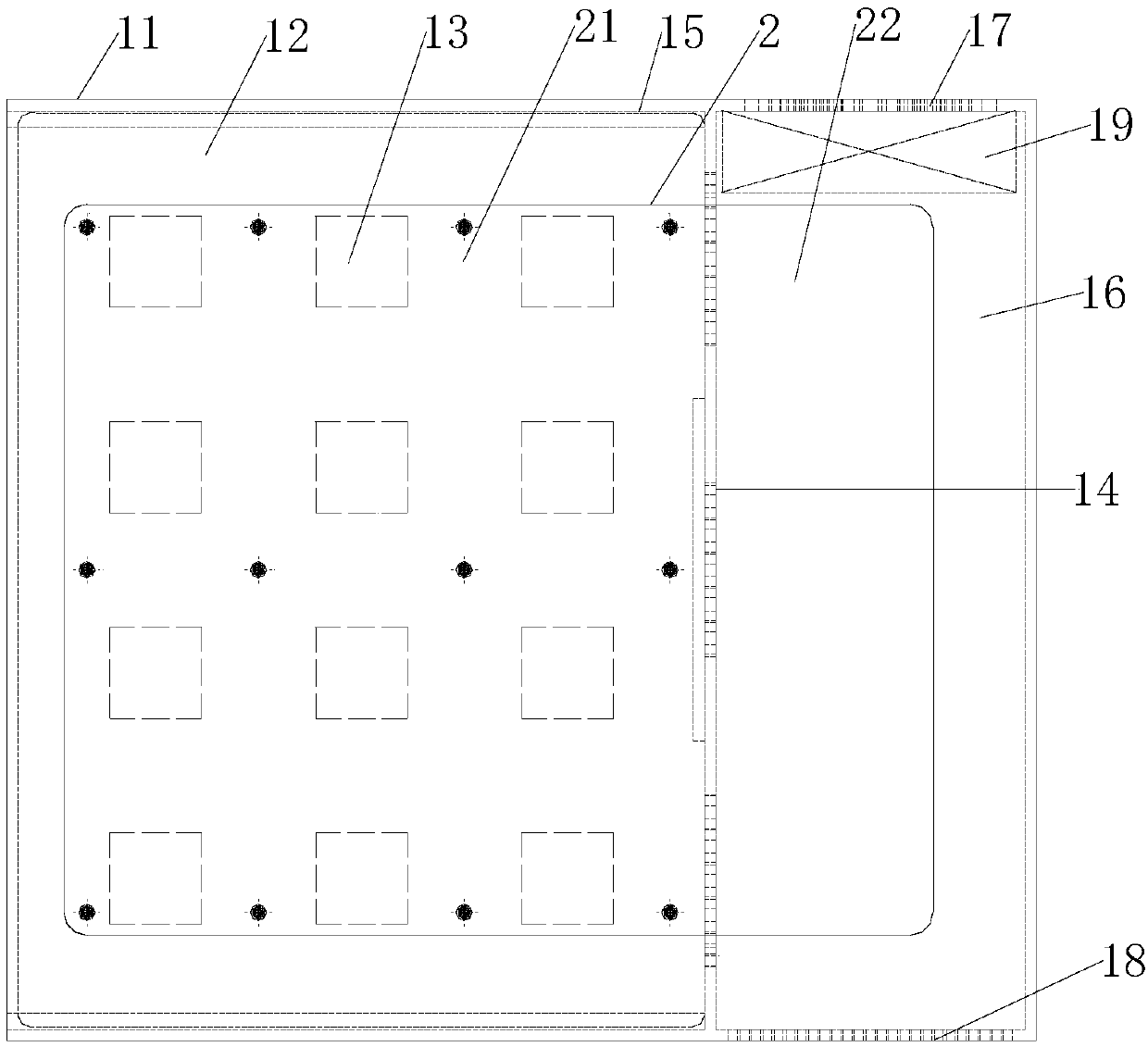

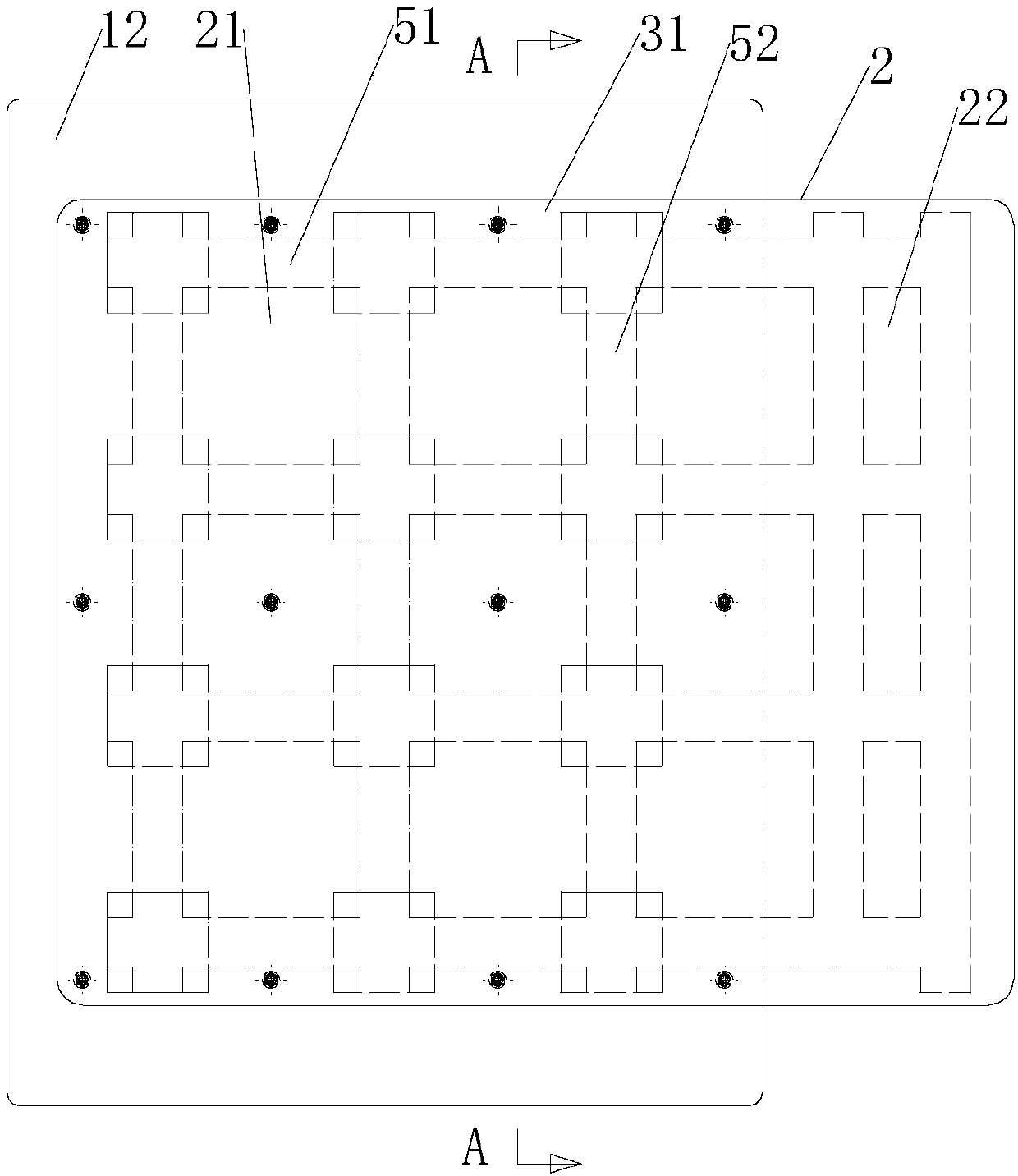

[0040] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the circuit board air-cooled heat dissipation device includes a chassis 11, a fan 19 and a heat conducting plate 2.

[0041] A slot 15 is provided in the chassis 11, and both sides of the circuit board 12 are inserted into the slot 15; there are no less than two circuit boards 12, and multiple circuit boards 12 are vertically arranged side by side. One end of the cabinet 11 is provided with a cooling chamber 16, and a partition 14 is arranged between the cabinet 11 and the cooling chamber 16. The partition 14 is provided with cooling holes and jacks, and the cooling holes and the jacks all connect the cabinet 11 with the cooling chamber 16. , The cooling chamber 16 is also provided with an air inlet 18 and an air outlet 17, and the fan 19 is installed on the air outlet 17.

[0042] The circuit board 12 is equipped with a heat conduction plate 2, the heat conduction plate 2 includes a heat conduction are...

Embodiment 2

[0048] Such as figure 1 , figure 2 , Figure 5 and Figure 6 As shown, the circuit board air-cooled heat dissipation device includes a chassis 11, a fan 19 and a heat conducting plate 2.

[0049] A slot 15 is provided in the chassis 11, and both sides of the circuit board 12 are inserted into the slot 15; there are no less than two circuit boards 12, and multiple circuit boards 12 are vertically arranged side by side. One end of the cabinet 11 is provided with a cooling chamber 16, and a partition 14 is arranged between the cabinet 11 and the cooling chamber 16. The partition 14 is provided with cooling holes and jacks, and the cooling holes and the jacks all connect the cabinet 11 with the cooling chamber 16. , The cooling chamber 16 is also provided with an air inlet 18 and an air outlet 17, and the fan 19 is installed on the air outlet 17.

[0050] The circuit board 12 is equipped with a heat conduction plate 2, the heat conduction plate 2 includes a heat conduction ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com