Robot punching system for automobile covering part and punching method of automobile covering part

A technology for automotive panels and robots, which is applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of dwelling, no advantage in hole-making quality, and no literature reports, so as to reduce R&D costs and shorten the R&D cycle , Improving the stamping quality of the workpiece and the effect of the life of the die

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

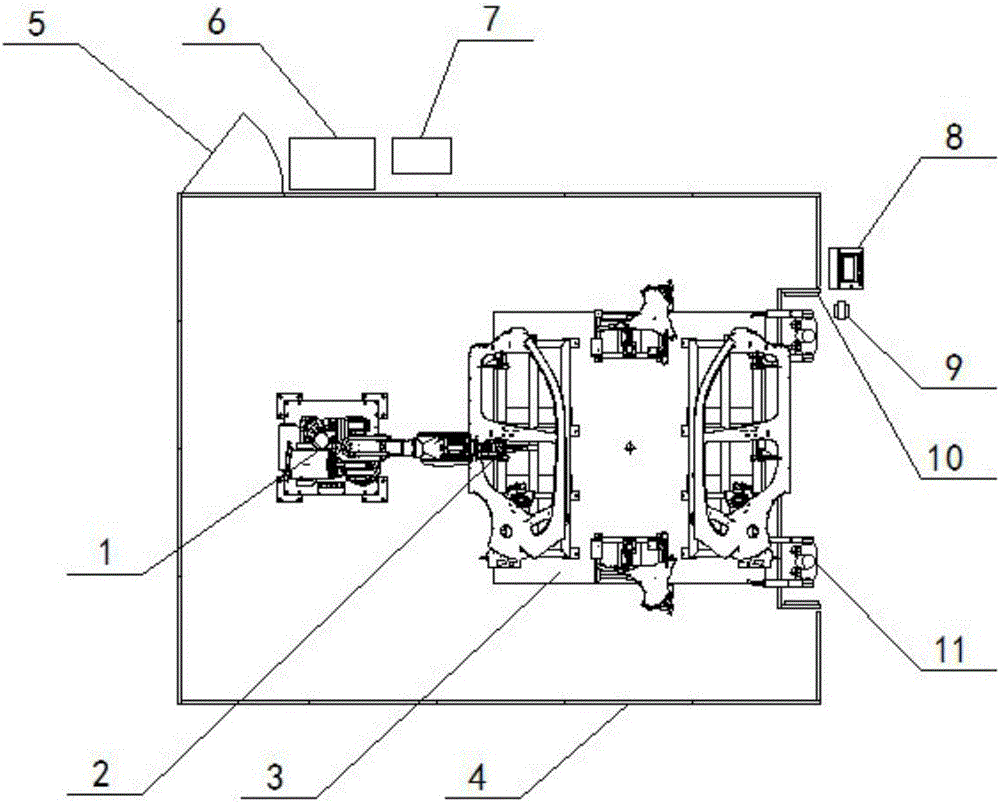

[0025] See figure 1 , the present invention includes a PLC control cabinet 6, a robot control cabinet 7, a touch screen operation panel 8, an operation button box 9 and a safety protection device.

[0026] The safety protection device includes a safety fence 4, a safety grating 10 and a safety door 5 installed on the periphery of the working area, which are respectively connected with the PLC control cabinet 6 for signals. The safety fence 4 is composed of an aluminum alloy frame and a metal mesh, which is safe and beautiful, and is convenient for observing the operation status of the equipment; the safety grating 10 is provided with two horizontal and vertical lines, which are installed on the periphery of the work area to increase the safety factor of workers; the safety door 5 is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com