Injector detection device

A detection device and injector technology, which is applied in the direction of fuel injection device, measuring device, machine/structural component testing, etc., can solve the problems of fluctuation of measurement results and influence of measurement results, etc., and achieve simplified operation, improved accuracy, and improved repeatability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

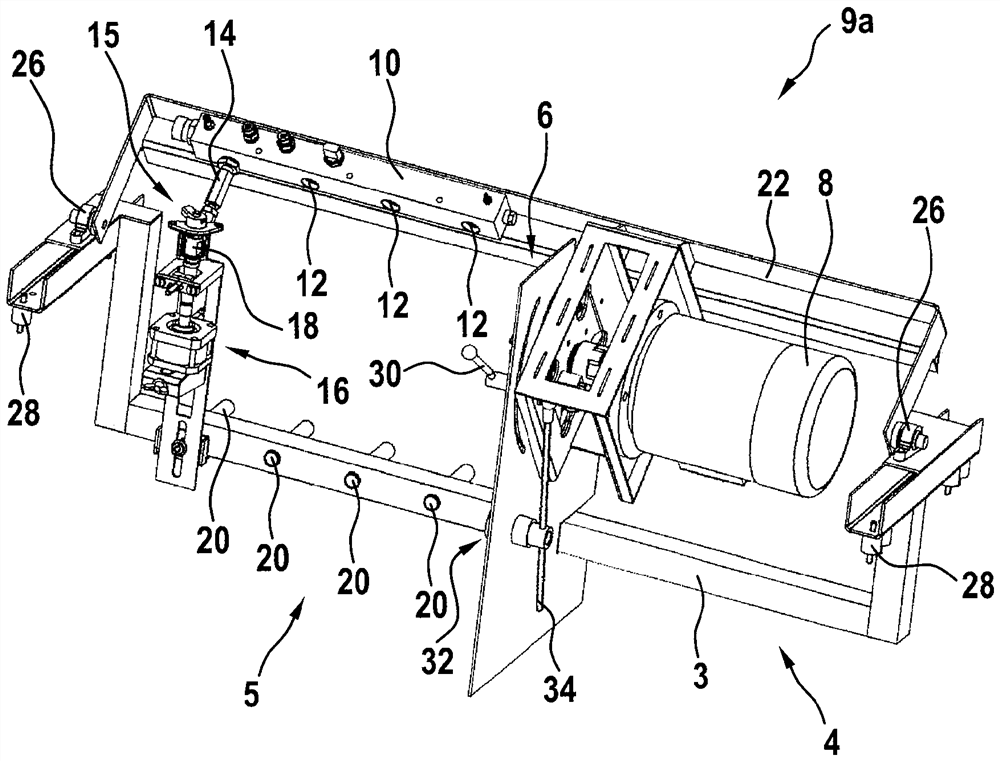

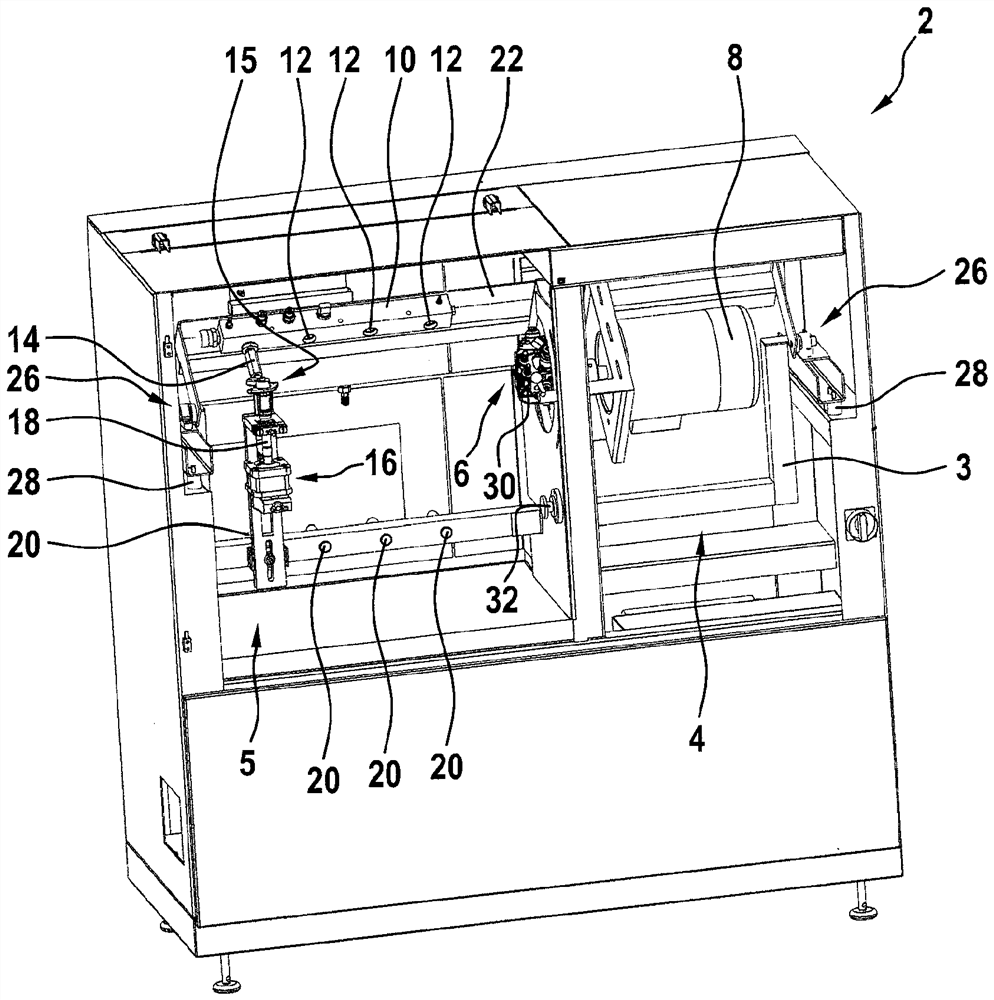

[0024] figure 1 Shows a front perspective view of an injector 2 detecting means 9a assembly embodiment of the present invention. Figure 2A and 2b From two different angles shows a perspective view of an assembly comprising a functional element 9a of the injector detecting means 2.

[0025] Injector 2 comprises detecting means figure 1 , 2a And 2b, respectively, shown on the right of the pressure generation region 4 and a detection region 5 on the left side are shown.

[0026] Injector detecting means 2 has a support frame 3, the support frame supporting the fluid pump (high pressure pump) 6 is configured for driving the fluid pump 6 and the motor 8.

[0027] The swingable frame 22 through the two bearing housing 26 is thus supported on the support frame 3, so that it can pivot about a horizontal axis. This implementation is possible to swing the frame 22 about a horizontal axis from the horizontal to the vertical at an arbitrary angle adjustment. The swingable frame 22 is fixed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com