Steam box

A technology of steaming boxes and steaming plates, which is applied in the field of steaming boxes, can solve the problems of huge demand, high labor costs, difficulty in adapting to large-scale supply needs, etc., and achieve the effect of improving cooking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is attached Figure 1-18 Specific embodiments of the present invention will be described in detail.

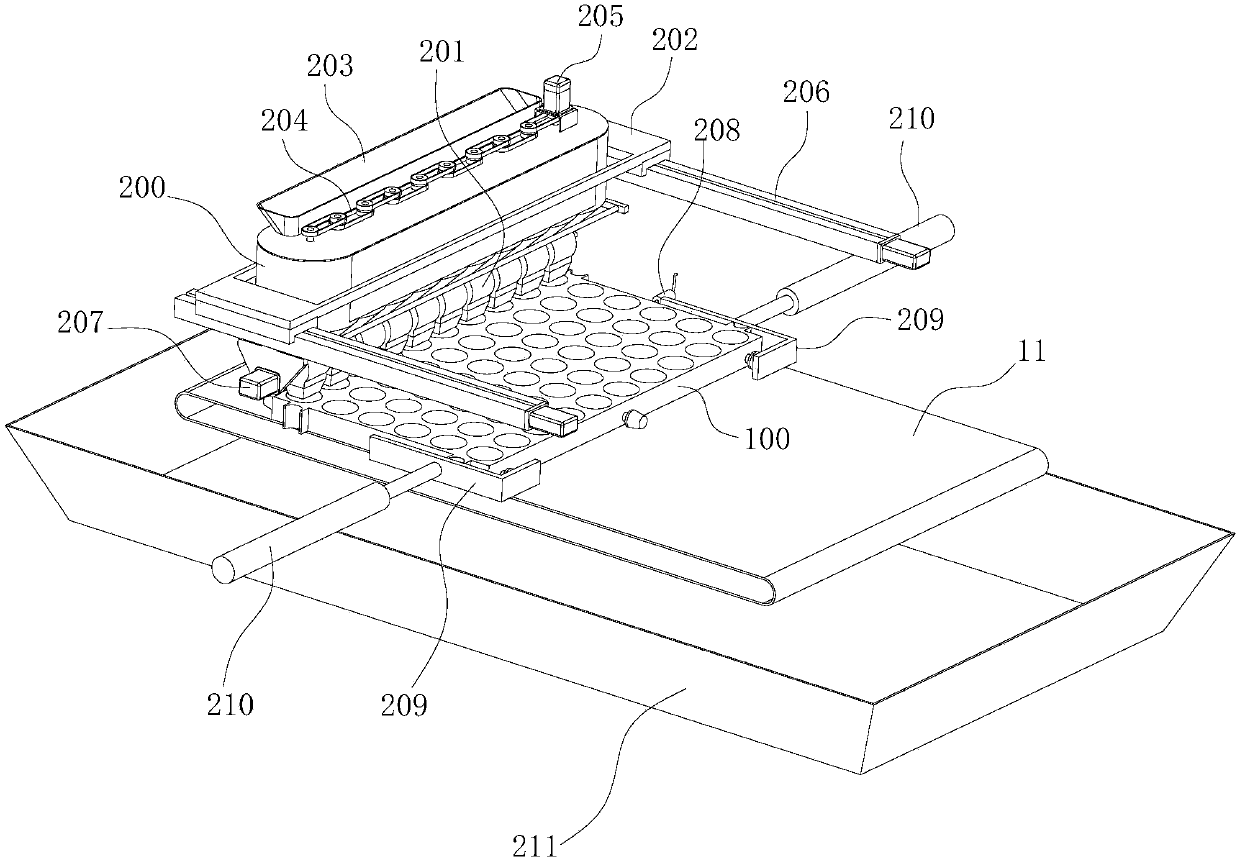

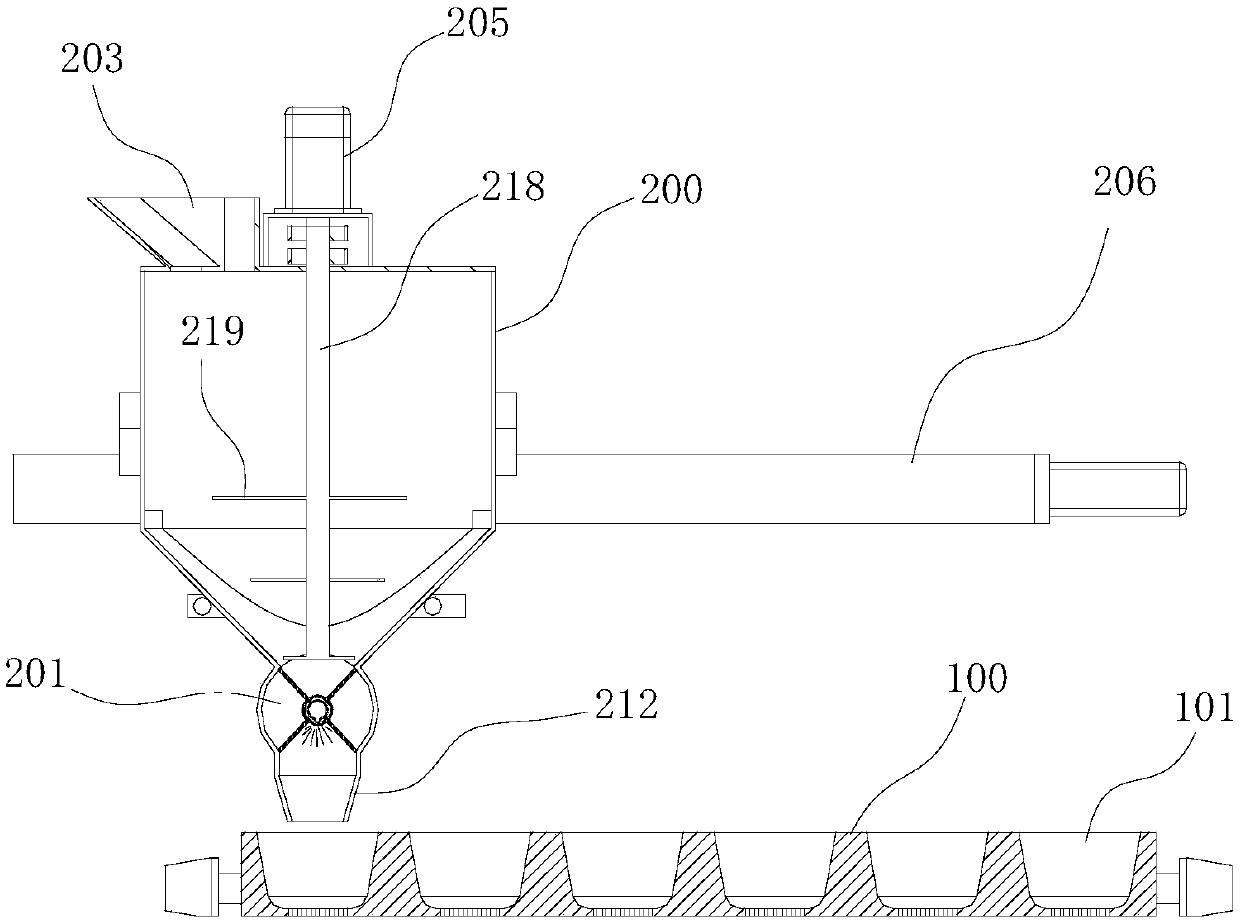

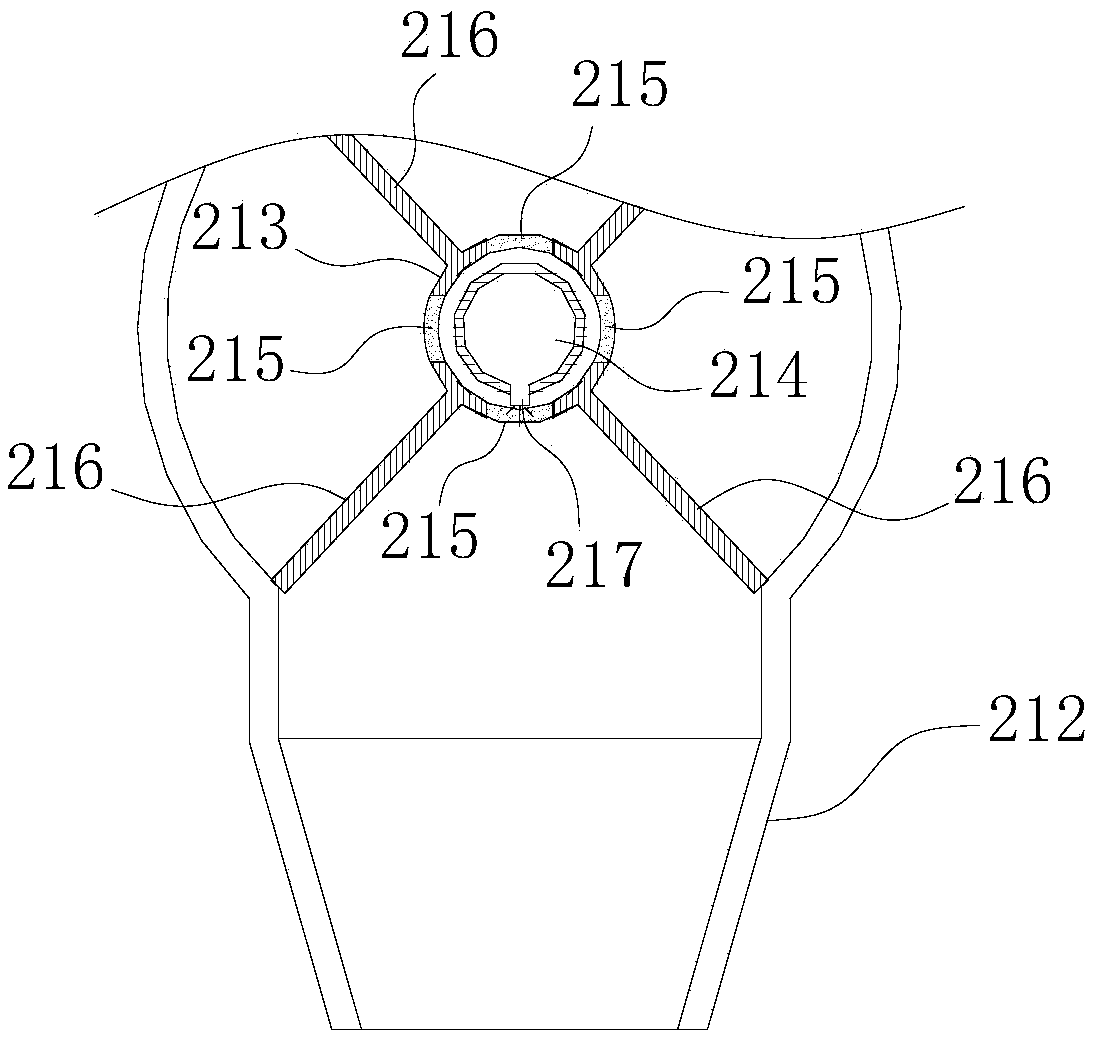

[0032] A rice production and processing system, comprising a steaming plate 100, a template 500, a distributing device, a steaming box, a lunch box arranging device, a boxing device, and a packaging and unloading device; The conveying mechanism is sequentially connected, and the first conveying mechanism is used to transfer the steaming plate 100; the lunch box arranging device, the box loading device, and the packaging and unloading device are sequentially connected through the second conveying, and the second conveying mechanism for transporting said template 500;

[0033] Such as figure 1 As shown, a plurality of independent grooves 101 are arranged in an array on the steaming plate 100 for accommodating soaked rice, and each groove 101 has a water seepage hole 102 at the bottom, and the size of the water seepage hole 102 is set To prevent the passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com