A stone crushing device used in water conservancy projects

A water conservancy project and stone crushing technology, which is applied in grain processing, etc., can solve the problems of economic waste, low stone crushing efficiency, unqualified, etc., and achieve the effect of improving work efficiency, better crushing effect, and improving pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

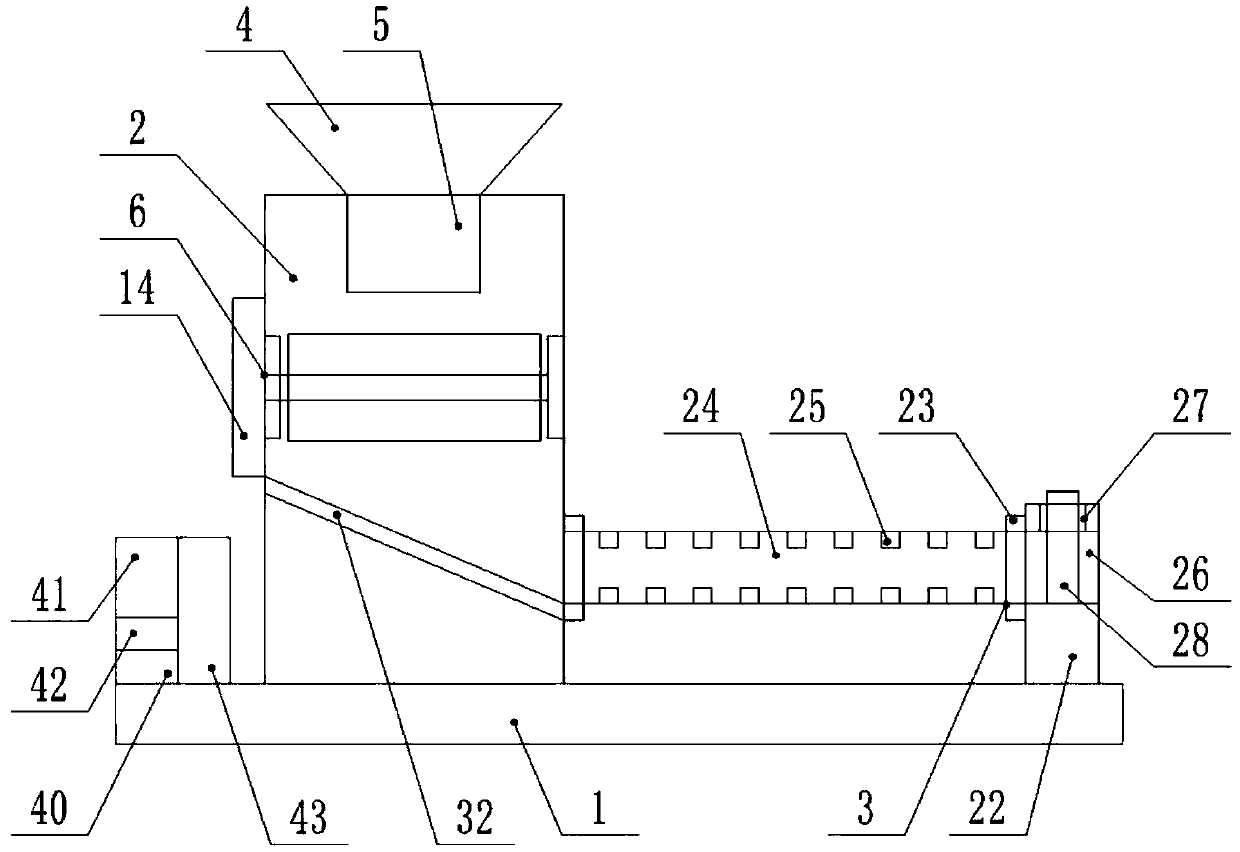

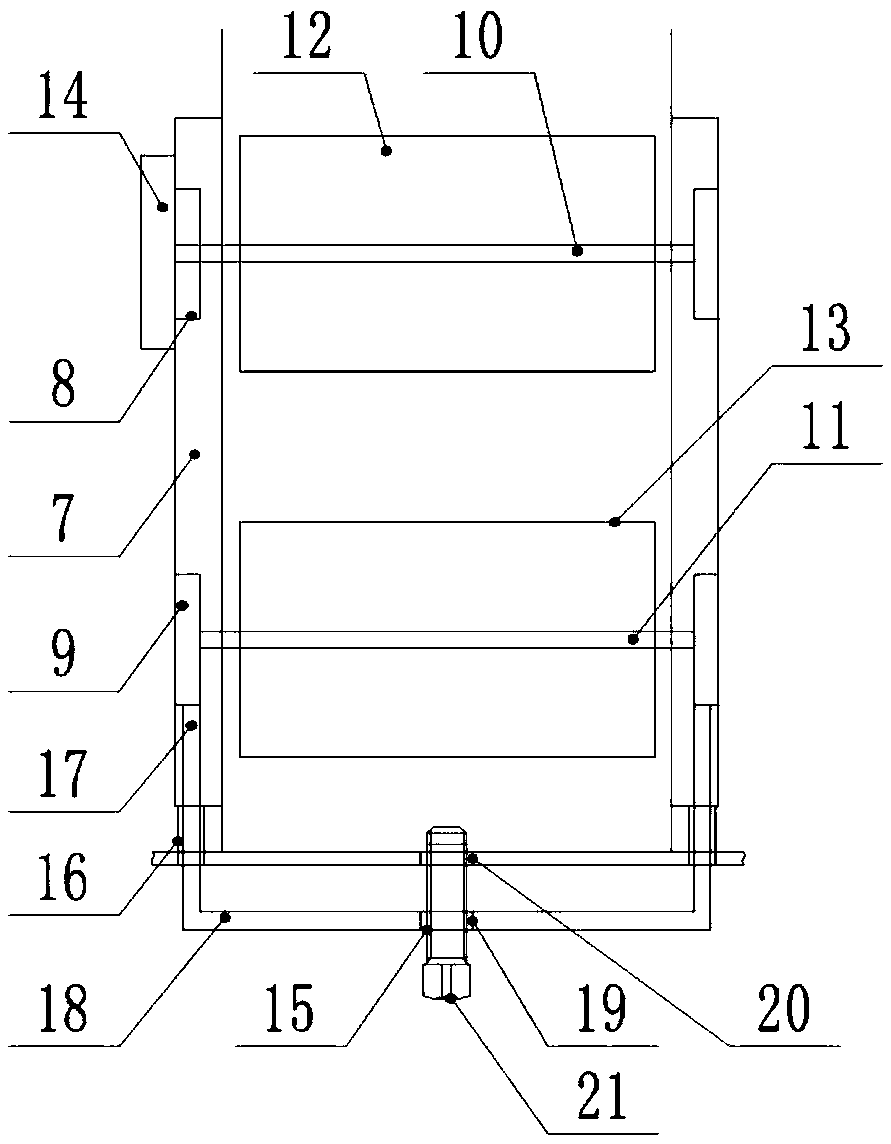

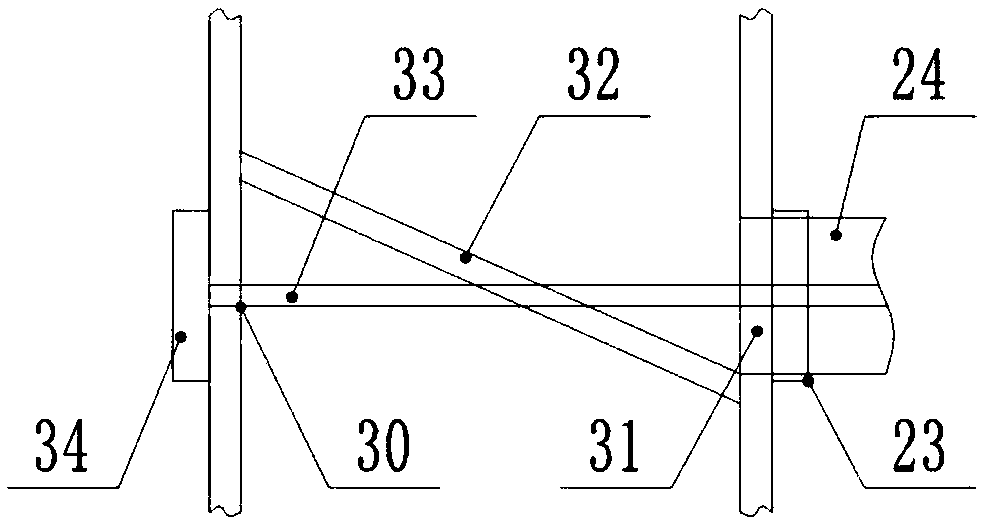

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4As shown, a stone crushing device used in water conservancy projects includes a basic rectangular base 1, and the upper end of the basic rectangular base 1 is provided with a primary crushing box 2 and a secondary crushing drum device 3, and the primary crushing The upper end of the box body 2 is provided with a feed funnel 4, and the lower end of the feed funnel 4 communicates with the inner cavity of the upper end of the primary gravel box 2 through the feed cylinder 5, and the upper end of the inner cavity of the primary gravel box 2 corresponds to The position of the discharge end of the feeding barrel 5 is provided with a primary stone crushing device 6, and the primary stone crushing device 6 is separated from the inner walls on the left and right sides of the upper end of the primary stone crushing box 2 and along the front and rear directions correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com