Wheel set withdrawing machine provided with clamping key structure wheel withdrawing seat capable of being used bi-directionally

A technology for removing wheel seats and unloading machines, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of elasticity and deformation of wheelsets that cannot be removed from brake discs, and achieve reasonable structure, high strength, good workmanship effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

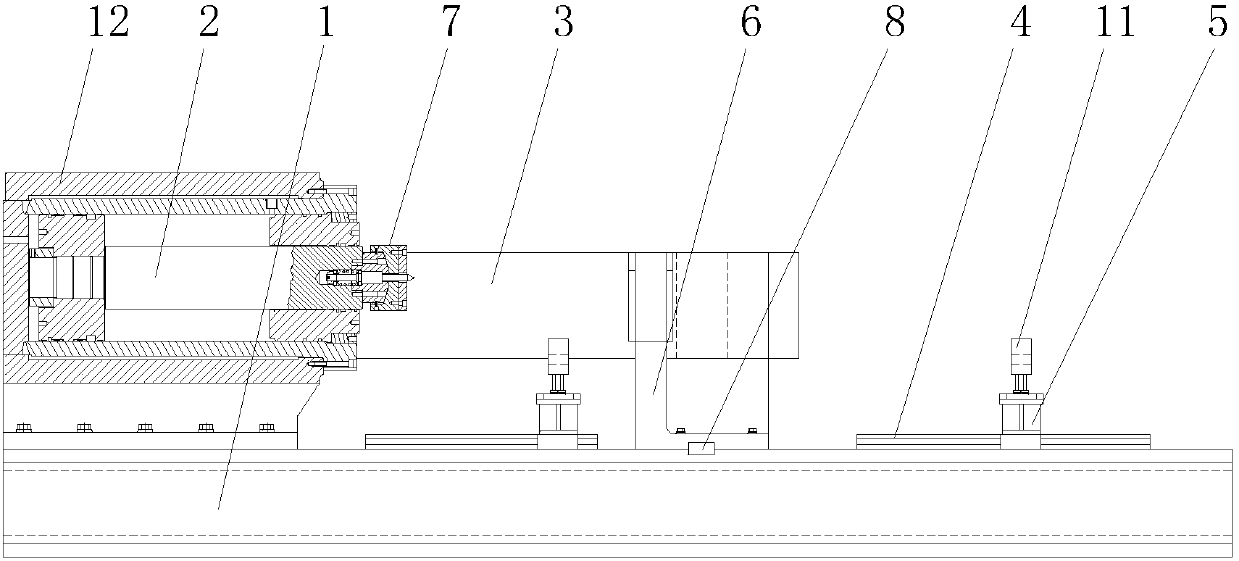

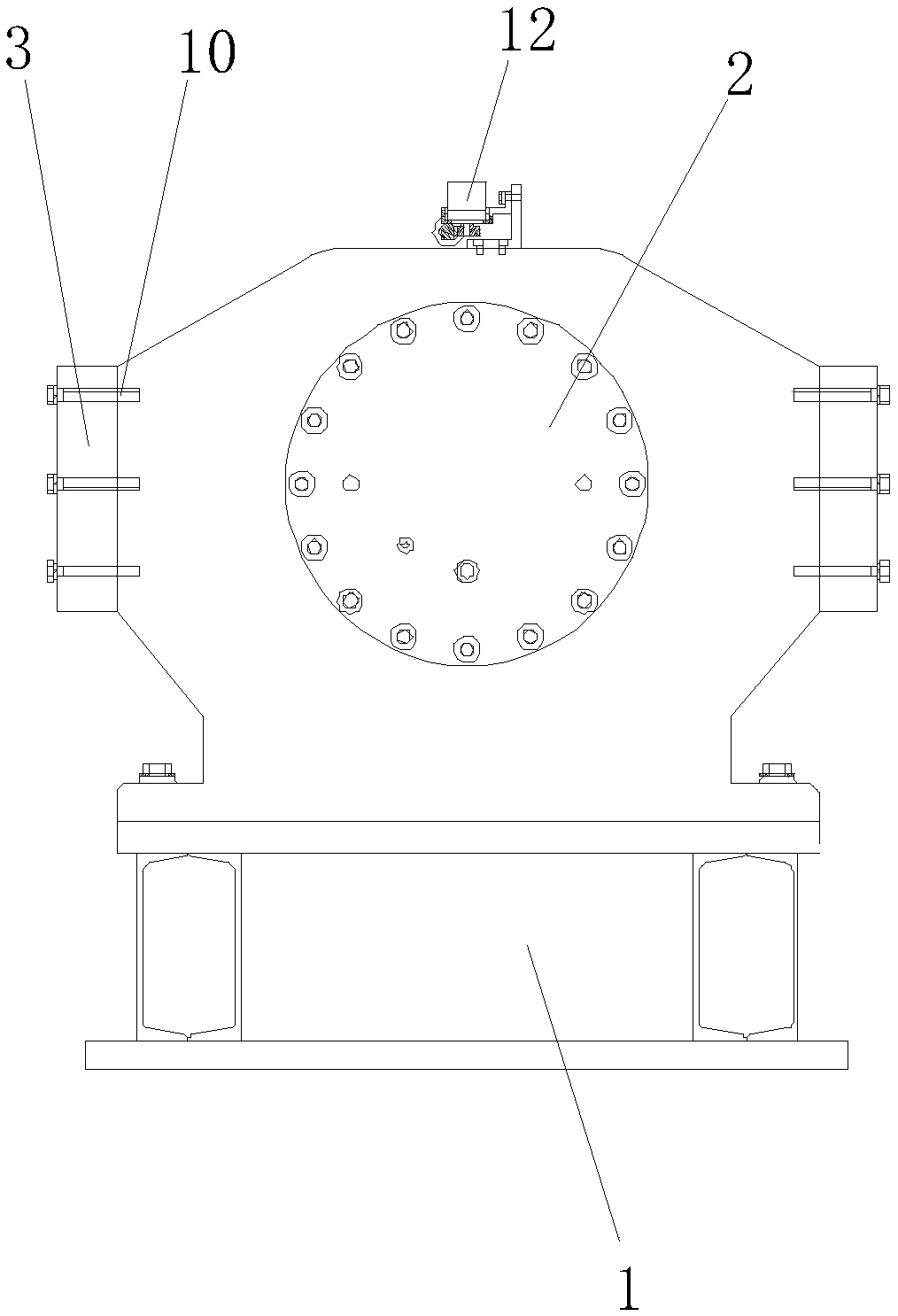

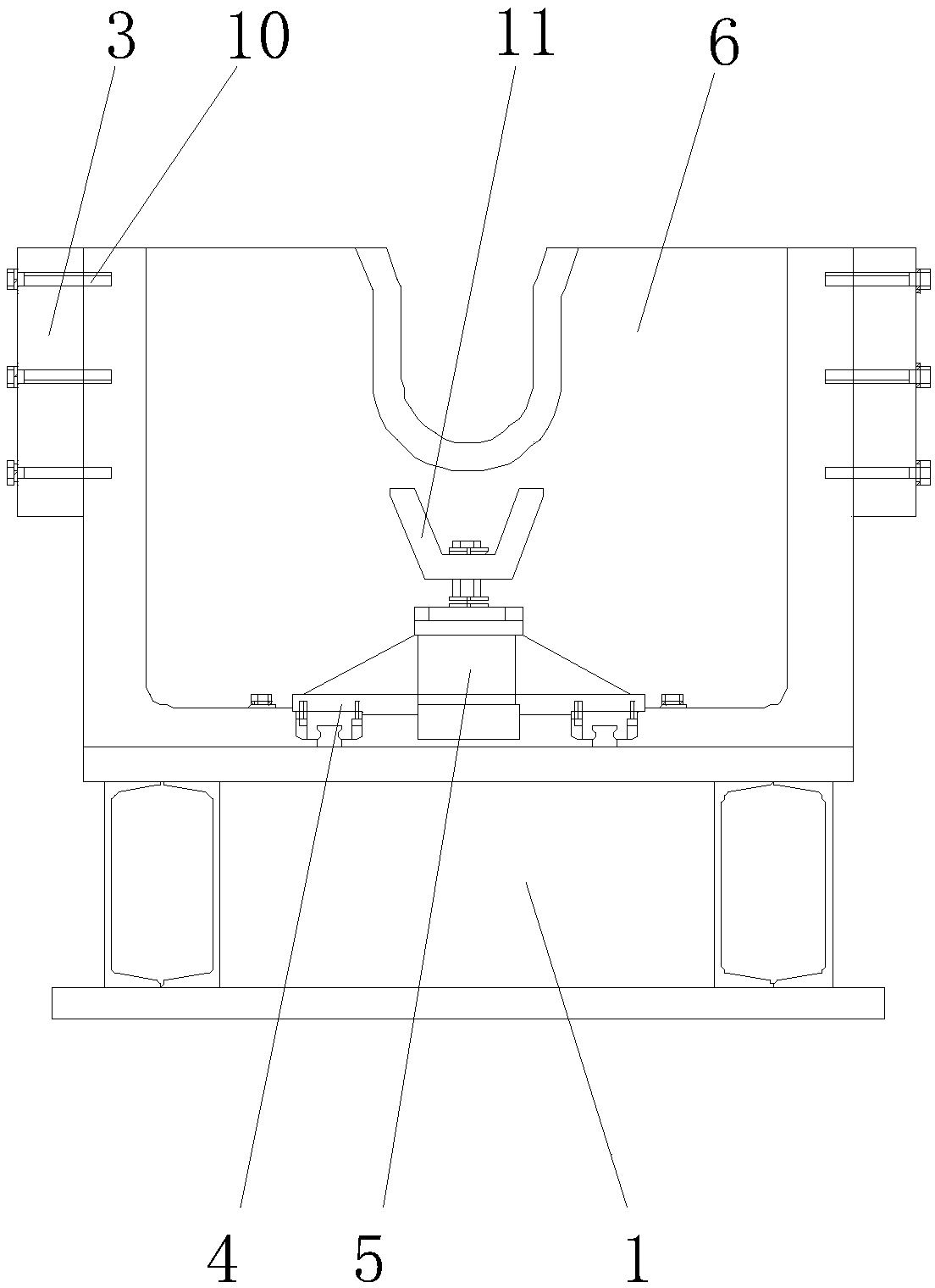

[0028] to combine Figure 1 to Figure 4 As shown, a wheel set unloading machine with a two-way use card key structure unloading seat, including base 1, unloading hydraulic cylinder 2, side pull plate 3, linear track 4, jacking cylinder 5 and unloading seat 6. The unloading hydraulic cylinder 2 is set at one end of the base 1, the output end of the unloading hydraulic cylinder 2 is provided with a flexible top 7, and there are two side pull plates 3, which are respectively set on both sides of the base 1, and the pulley seat 6 is located in the middle of the base 1, and two side pull plates 3 fixedly connect the unloading hydraulic cylinder 2 and the unloading wheel base 6 from both sides. The linear track 4 is divided into two groups, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com