Gap type water draining pipe mold and forming method

A technology for molding molds and drainage pipes, which is applied in the direction of ceramic molding machines, ceramic molding cores, ceramic molding mandrels, etc., which can solve problems such as unfavorable concrete pouring, inability to achieve reliable support, and troublesome mold loading operations, etc. The mechanism is convenient, stable and reliable, easy to operate, convenient to inflate and deflate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

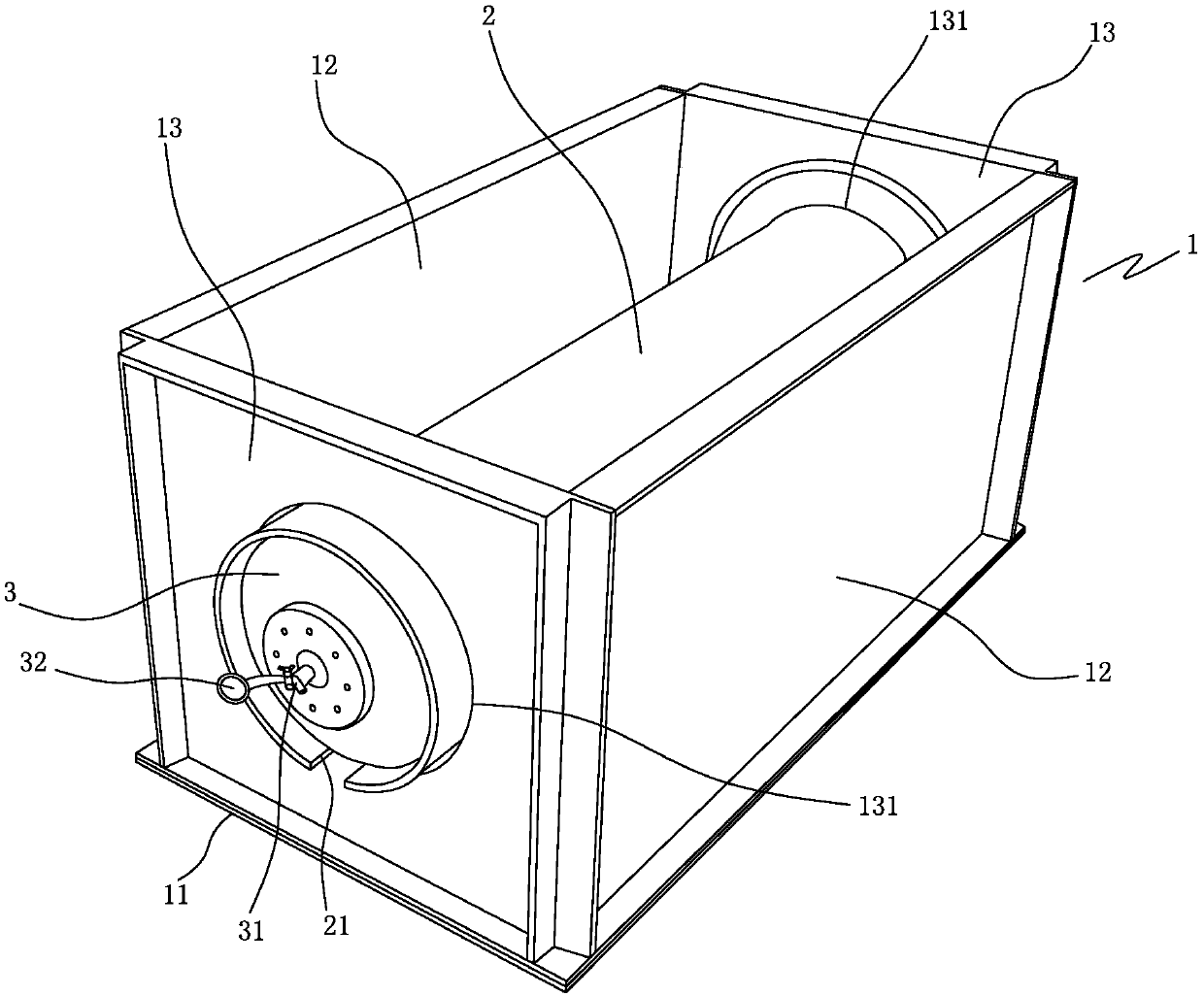

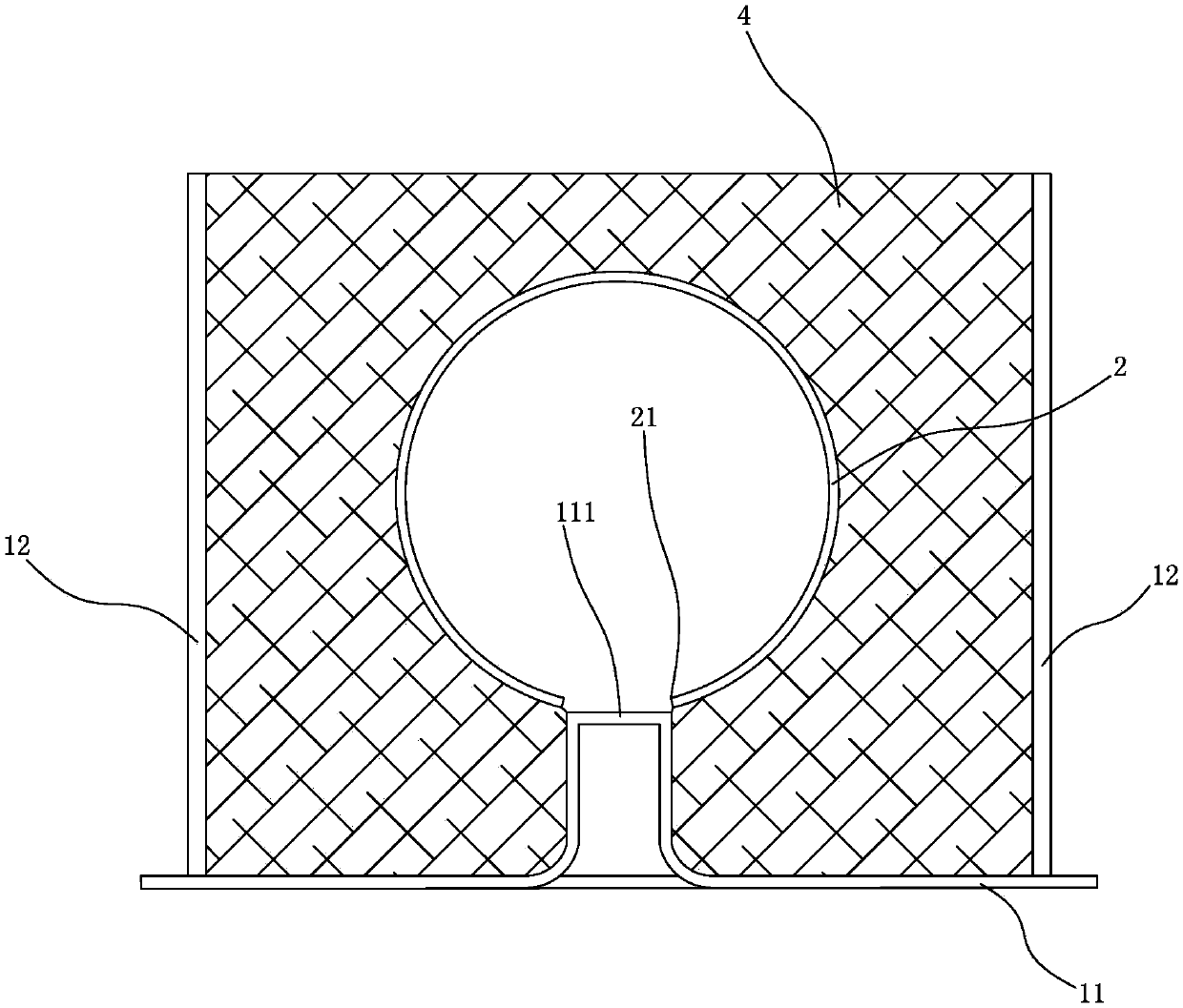

[0026] refer to figure 1 , figure 2 and image 3 As shown, a slotted drainage pipe forming mold includes a mold frame 1, a slotted pipe 2, and an air bag 3.

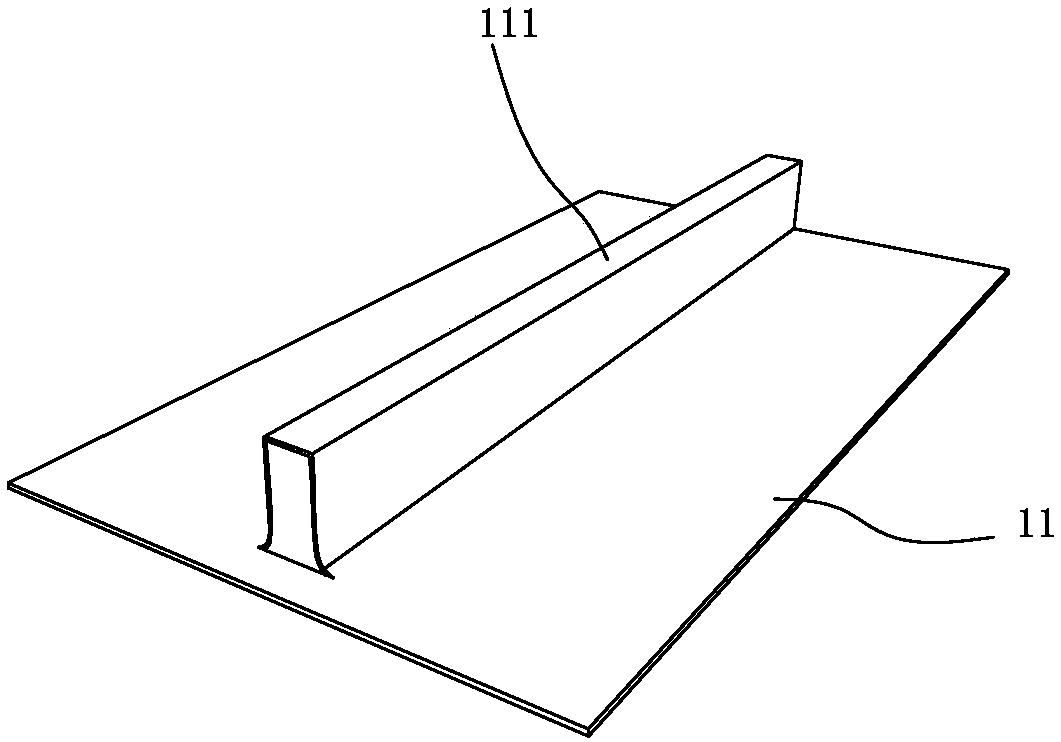

[0027] The mold frame 1 comprises a bottom plate 11, parallel opposite side plates 12 and parallel opposite end plates 13, the bottom plate 11, the two side plates 12 and the two end plates 13 encircle a rectangular parallelepiped trough with the opening upward, the bottom plate 11, the two The side plates 12 and the two end plates 13 are detachably connected by bolts, a sealing strip is provided between the joint surfaces of the two side plates 12 and the two end plates 13, and the two end plates 13 are respectively formed with holes for the slotted pipe 2 to pass through. Make way hole 131, the slit pipe 2 is formed with the slit 21 along its length direction, the slit pipe 2 can be arranged in the mold frame 1 through the make way hole 131 transversely through the trough, and the bottom plate 11 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com