Self-induction self-collection umbrella cloth crimping machine

A self-collecting, edge-pressing machine technology, applied in applications, household components, household appliances, etc., can solve the problems of uncontrollable costs, manpower, material resources, and time-consuming, so as to ensure accuracy, improve production efficiency, The effect of high-quality edge pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

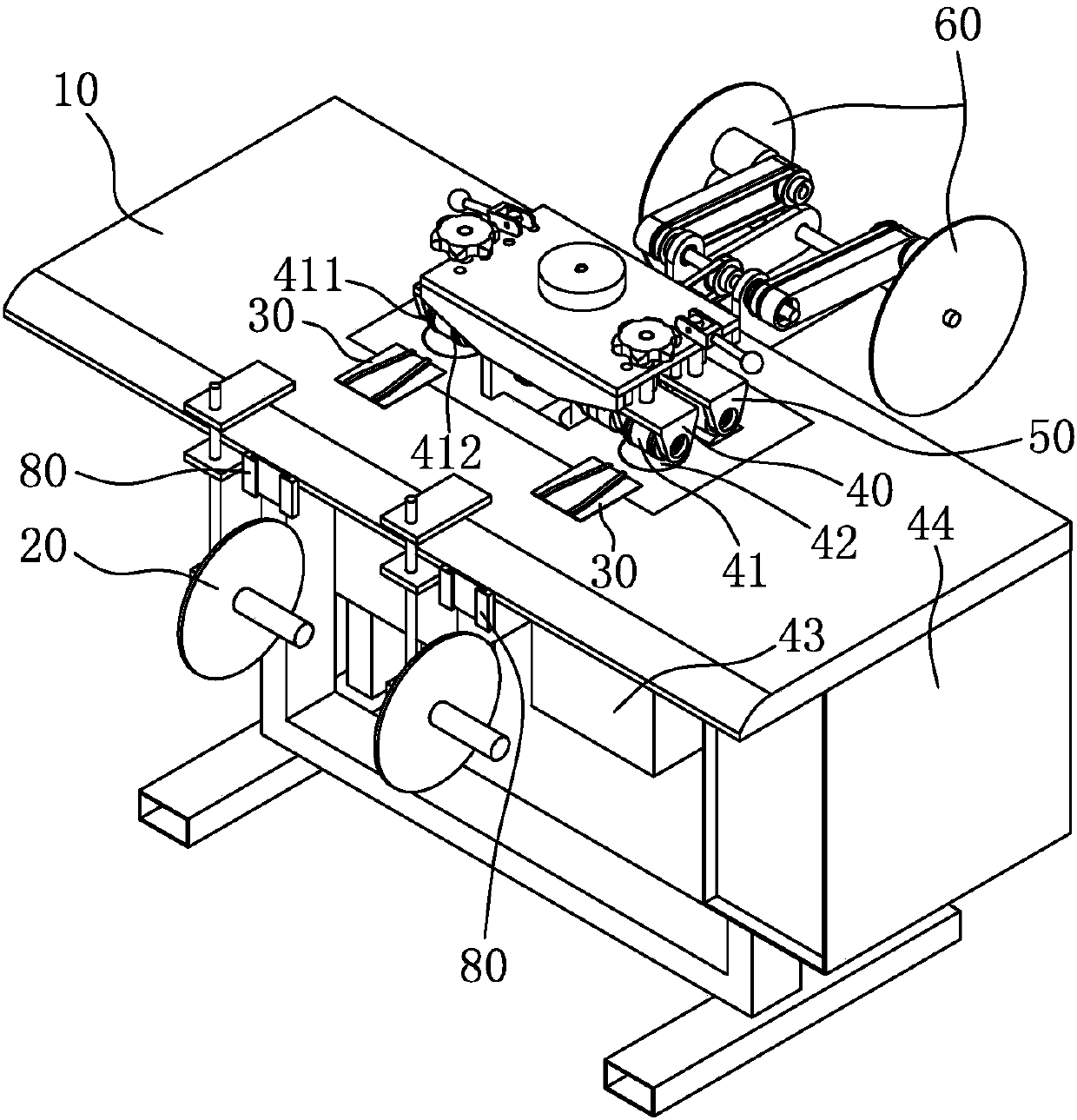

[0035] Such as Figure 1 to Figure 7 As shown, it is a preferred embodiment of a self-induction and self-collection umbrella cloth edge pressing machine related to the present invention.

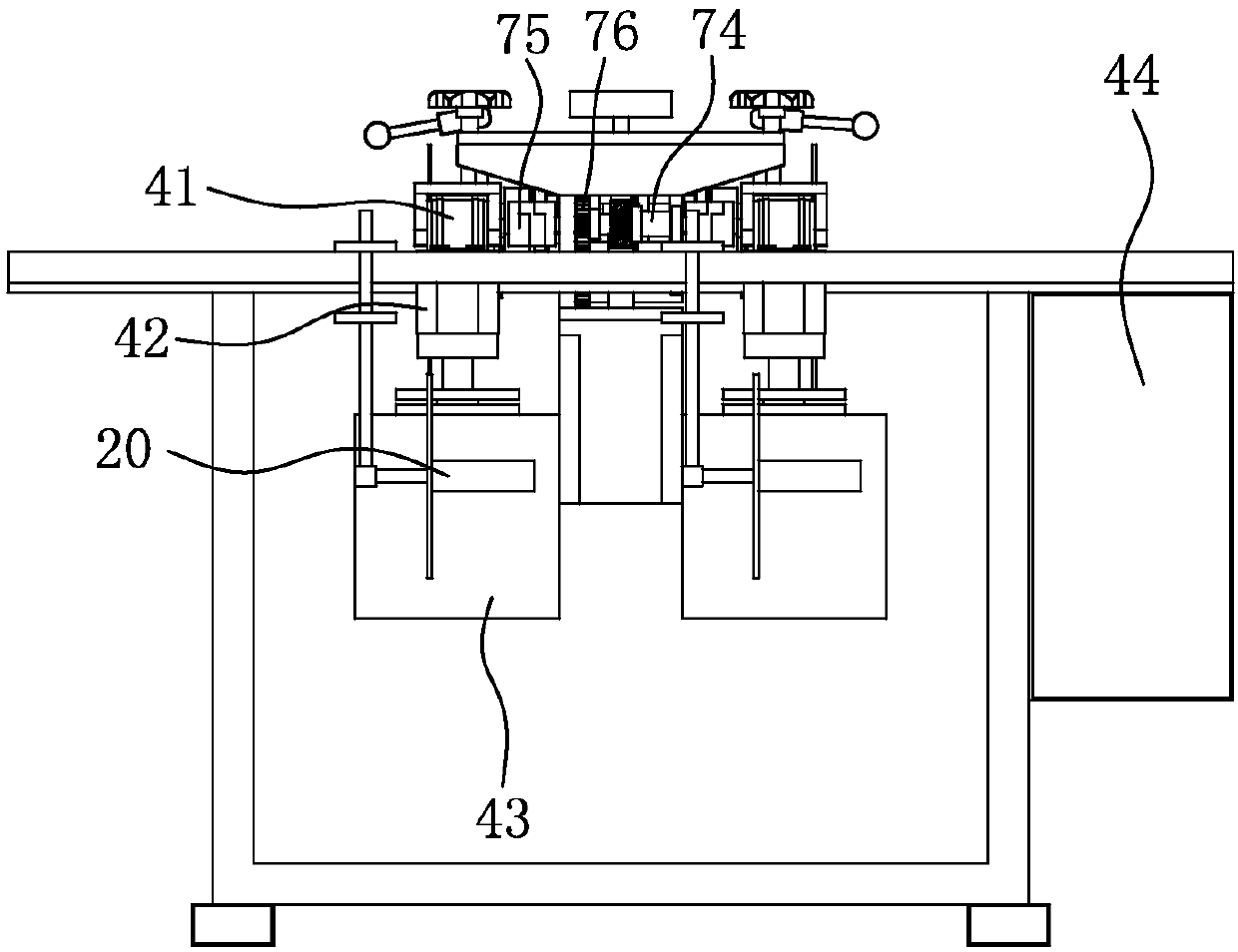

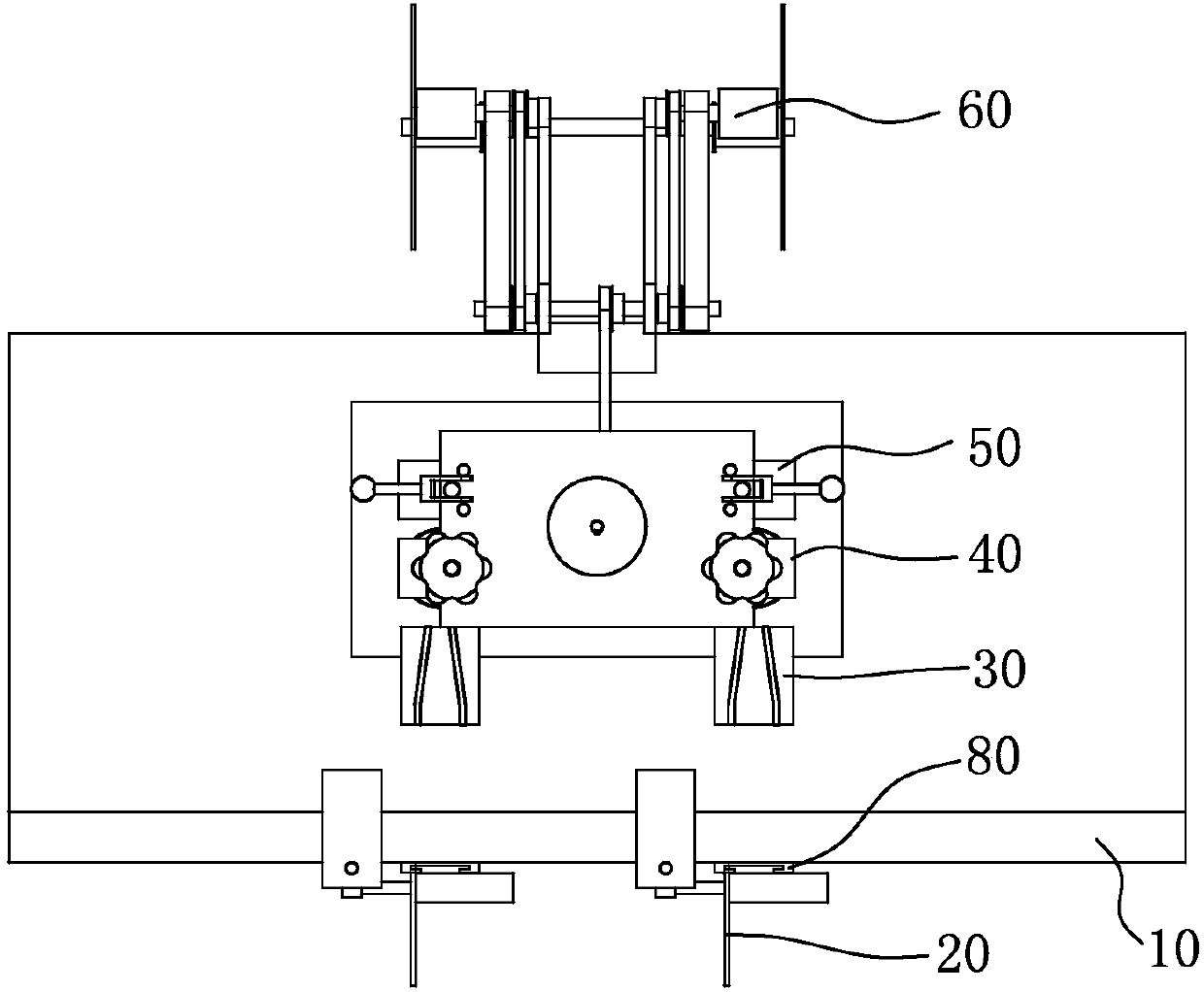

[0036] Such as Figure 1 to Figure 3 As shown, the self-induction and self-collecting umbrella cloth edge pressing machine includes a frame 10, a cloth storage mechanism 20, an edge rolling mechanism 30, a pressing mechanism 40, a conveying mechanism 50, a cloth receiving mechanism 60, a power mechanism 70, and an umbrella cloth Sensing mechanism 80 and control mechanism (not shown in the figure).

[0037] Please refer to Figure 7 As shown, the power mechanism 70 has a power motor 71, a first helical gear 72, a second helical gear 73, a transmission shaft 74, an Oldham coupling 75, a power gear 76, a first transition gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com