Automatic letter stamping device of molded case circuit breaker heat element, and operating method thereof

A technology of molded case circuit breaker and thermal element, applied in stamping, printing and other directions, can solve the problems of unsatisfactory punching effect, weak adaptability, complex structure, etc., and achieve fast punching speed, smooth operation, and clear numbers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

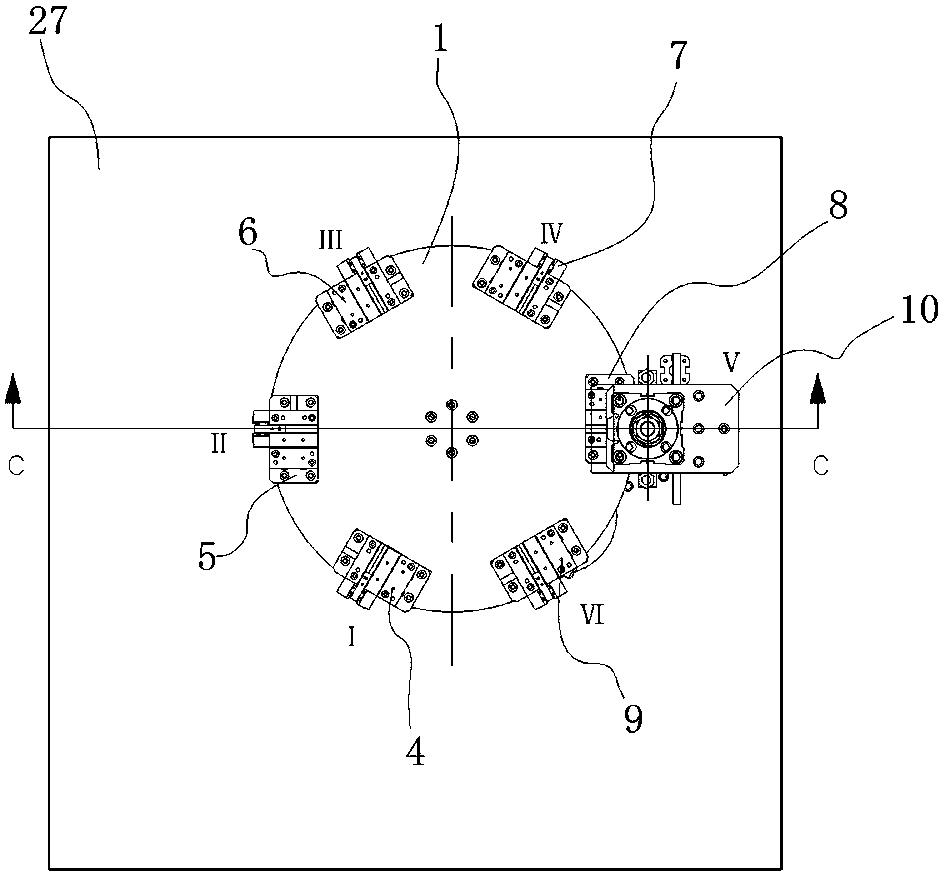

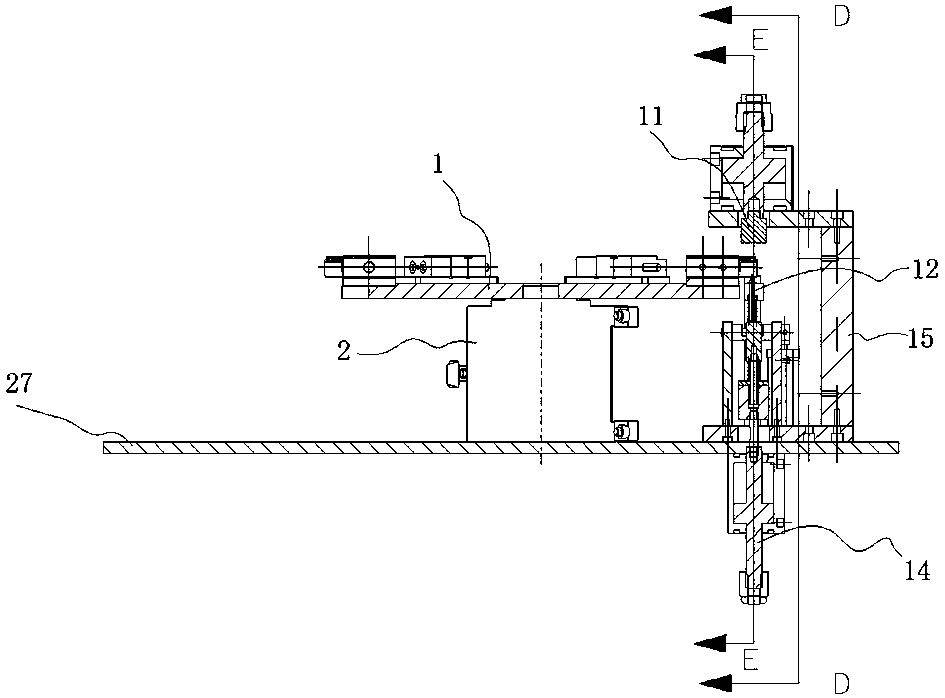

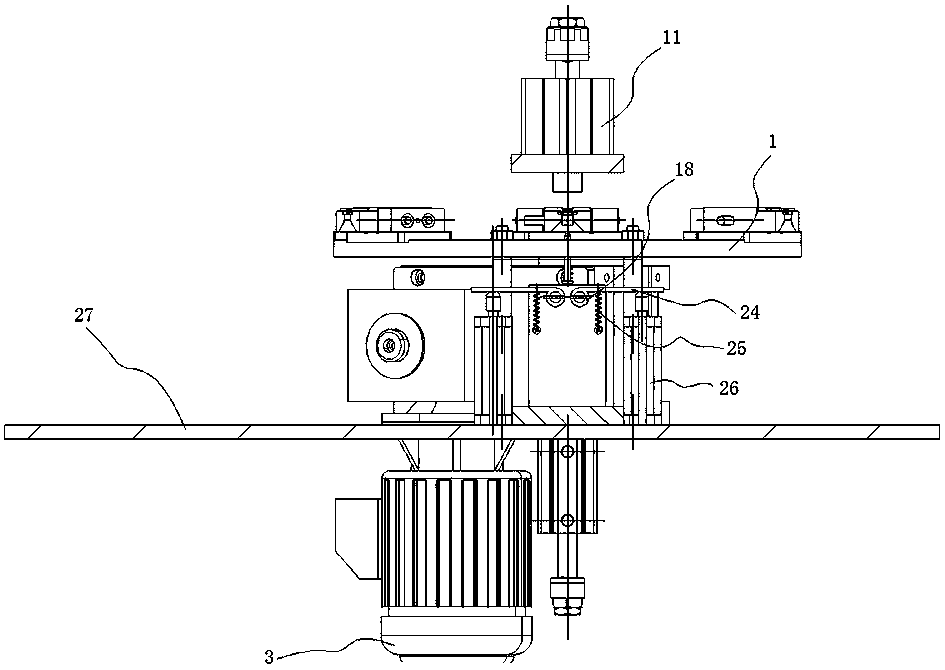

[0026] Embodiment 1: as figure 1 , figure 2 , image 3 with Figure 4 As shown, a molded case circuit breaker thermal element automatic punching device, including a turntable 1, the bottom of the turntable 1 is provided with a divider 2, the divider 2 is driven by a motor 3, including turntable 1 sequentially set There are copper support feeding station 4, flux station 5, heating element feeding station 6, resistance welding station 7, punching station 8 and unloading station 9 distributed in intervals. The outside of the 8 is provided with a punching system matched with the punching station 8;

[0027] The punching system includes an upper cylinder assembly and a lower cylinder assembly, the upper cylinder assembly includes an upper cylinder 11 arranged above the punching station 8, and the upper cylinder 11 and the punching station 8 are movable Crimping; the lower cylinder assembly includes a punch 12, a lock 13 and a lower cylinder 14, the upper part of the lower cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com