Cable guide self-adjusting device

A self-adjusting, cable technology, used in transportation and packaging, conveying filamentous materials, thin material handling, etc., can solve the problems of inconvenient operation, low device service life, wear of guide pulley mounting brackets, etc., and achieve easy installation or removal. , Improve the service life, the effect of fast fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

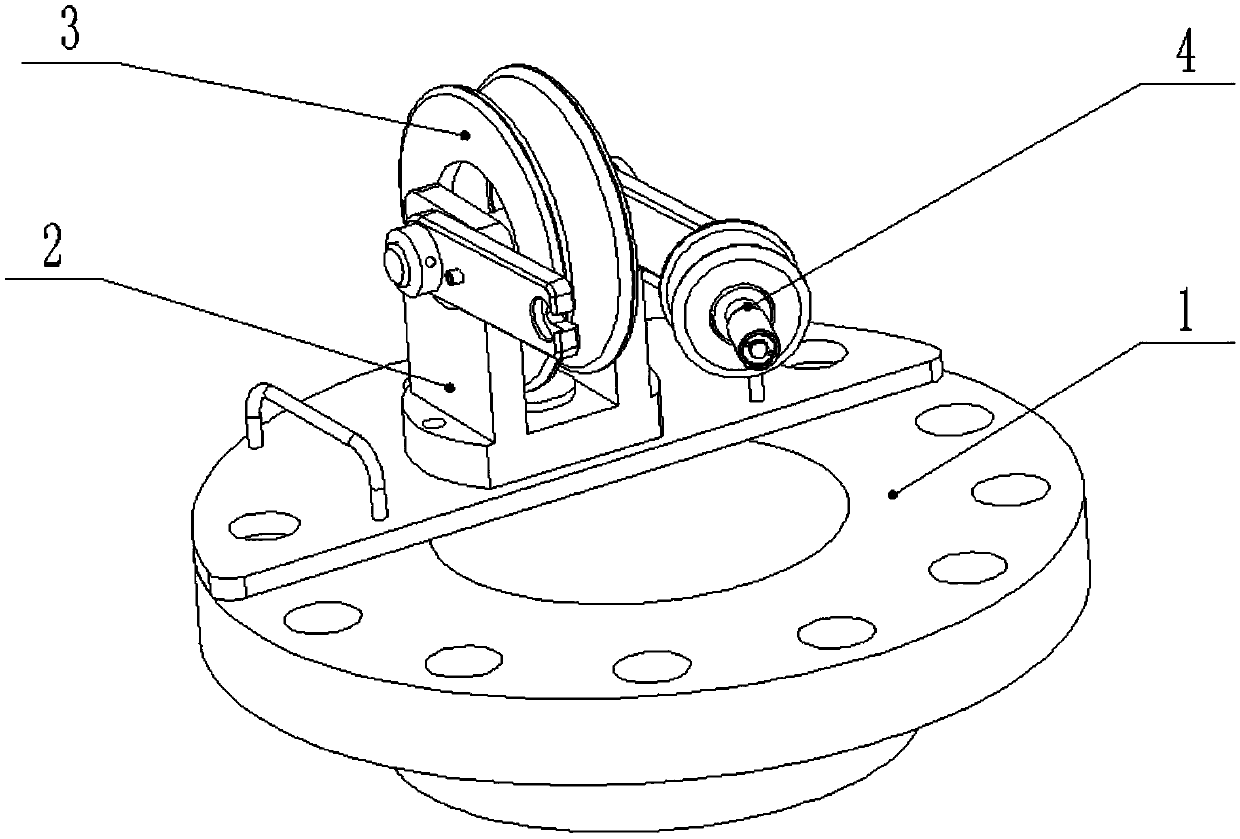

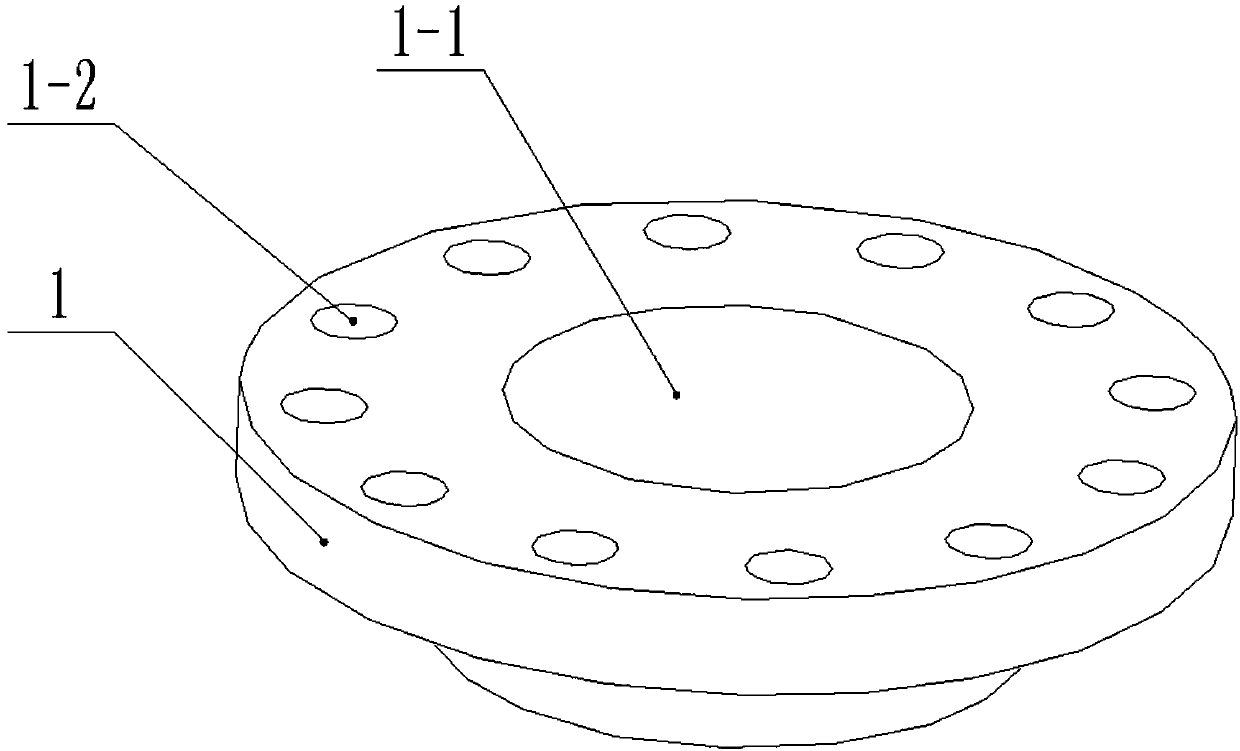

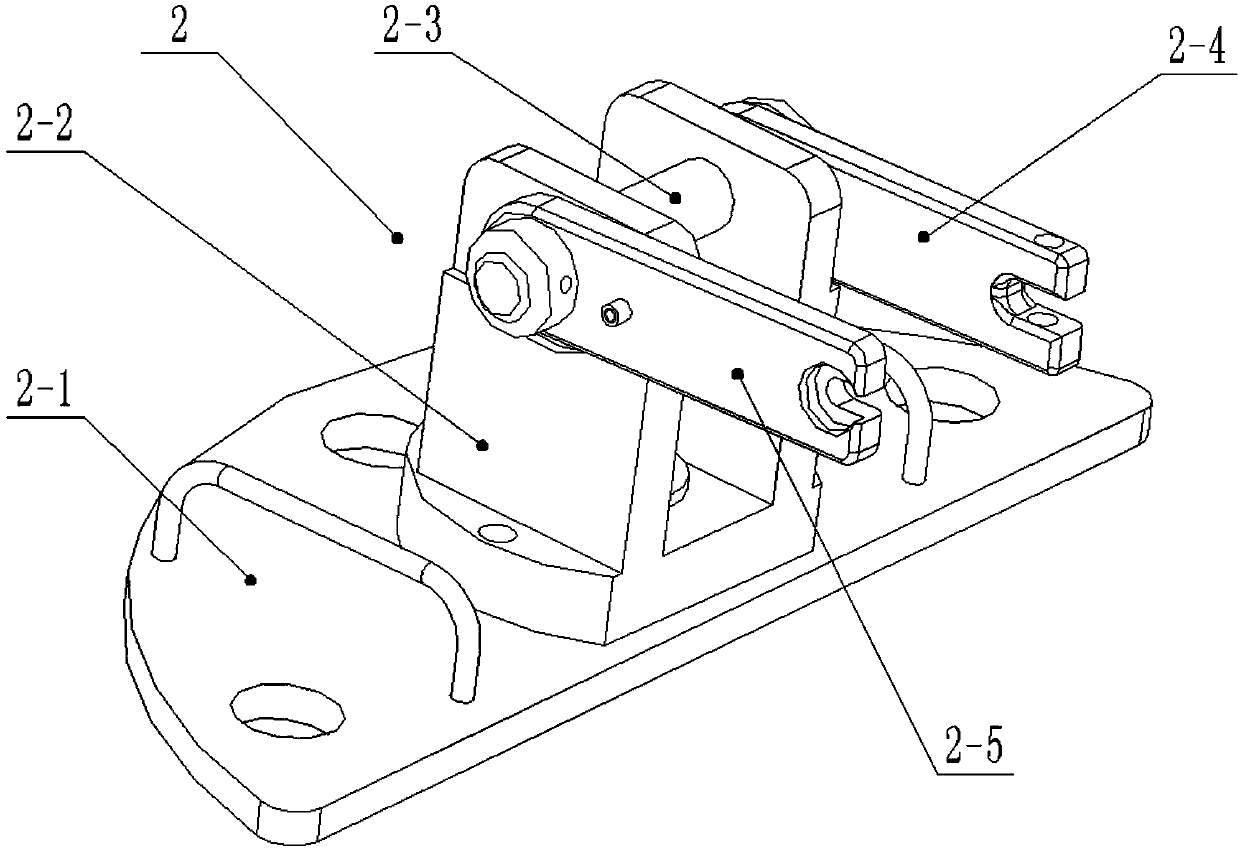

[0033] Combine below Figure 1-13 Describe this embodiment, a cable guide self-adjusting device, including a flange plate 1, a rotating base 2, a pulley 3 and an auxiliary wheel assembly 4, the rotating base 2 is fixedly connected to the upper end of the flange plate 1, and the pulley 3 Rotationally connected to the upper end of the rotating base 2, one end of the auxiliary wheel assembly 4 is hinged to the rotating base 2, and the other end of the auxiliary wheel assembly 4 is clamped on the rotating base 2; the rotating base 2 includes a base 2-1 , a swivel frame 2-2, an upper shaft 2-3, a support arm I2-4 and a support arm II2-5, the swivel frame 2-2 is rotatably connected to the upper end of the base 2-1, and the base 2-1 is fixedly connected On the flange 1, the upper rotating shaft 2-3 is rotatably connected to the upper end of the rotating frame 2-2, the pulley 3 is rotatably connected to the upper rotating shaft 2-3, the supporting arm I2-4 and the supporting arm II2 ...

specific Embodiment approach 2

[0034] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the first embodiment, the rotating base 2 also includes a lower rotating sleeve 2-6, an upper rotating sleeve 2-7 and a positioning bolt 2-8, and the lower rotating sleeve 2-6 The clearance fit is on the lower end of the rotating frame 2-2, the upper rotating sleeve 2-7 is clearance fitting on the upper end of the rotating frame 2-2, and the positioning bolts 2-8 pass through the upper rotating sleeve 2-7 sequentially from top to bottom and the lower rotating sleeve 2-6, the lower end of the positioning bolt 2-8 is threadedly connected to the base 2-1, when the rotating base 2 rotates, the lower rotating sleeve 2-6 contacts the upper rotating sleeve 2-7 to generate friction, and the The lower rotating sleeve 2-6 and the upper rotating sleeve 2-7 are made of wear-resistant materials, which can effectively prevent the friction loss when the rotating base 2 rotates, and improve the se...

specific Embodiment approach 3

[0035] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain Embodiment 2, there is a gap between the lower end surface of the rotating frame 2-2 and the upper end surface of the base 2-1, the gap is greater than 0.5mm, the rotating frame 2-2 Without being in contact with the base 2-1, when the rotating frame 2-2 rotates relative to the base 2-1, there will be no friction loss between the rotating frame 2-2 and the base 2-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com