Detection system and mixer

A technology of detection system and detection circuit, which is applied in the direction of radio wave measurement system, measurement device, geophysical measurement, etc., and can solve problems such as user safety hazards, stirring tool displacement, and affecting product use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

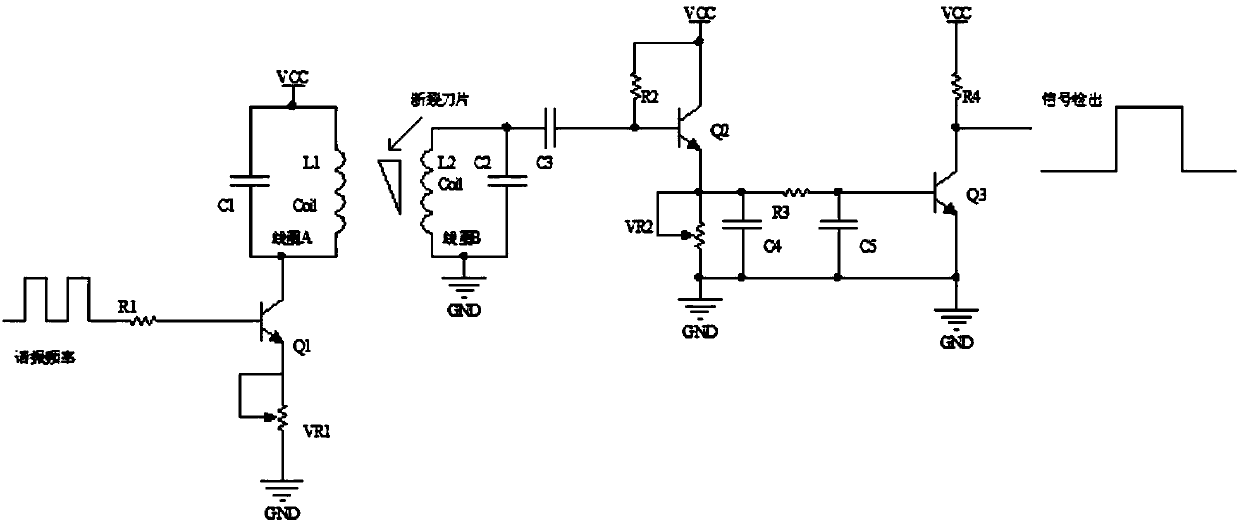

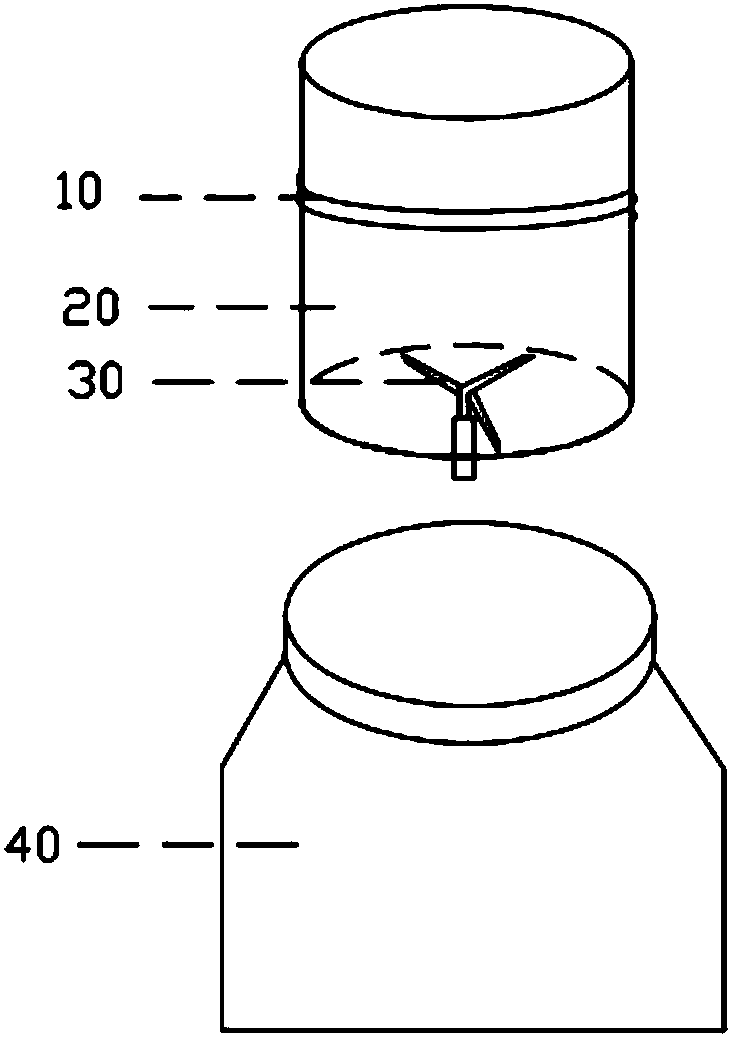

[0038] figure 1 It is a detection system provided by the embodiment of the present invention. The detection system is applied to stirring products. The above-mentioned stirring products should include a knife 30 for stirring operation; the detection system includes an induction device and a detection circuit. In an example, the induction device includes at least one induction coil 10, and the induction coil 10 is connected with the detection circuit. When the detection circuit is energized, the induction coil 10 is energized to generate an induced magnetic field. Within a stable numerical range, the normal operation of the cutter 30 mentioned here should be that the installation position of the cutter 30 has not changed, and the cutter 30 itself has no deformation and damage. In the embodiment of the present invention, when the cutting tool 30 is working normally, the induction coil 10 will output a normal working signal to the detection circuit, and the detection circuit will...

Embodiment 2

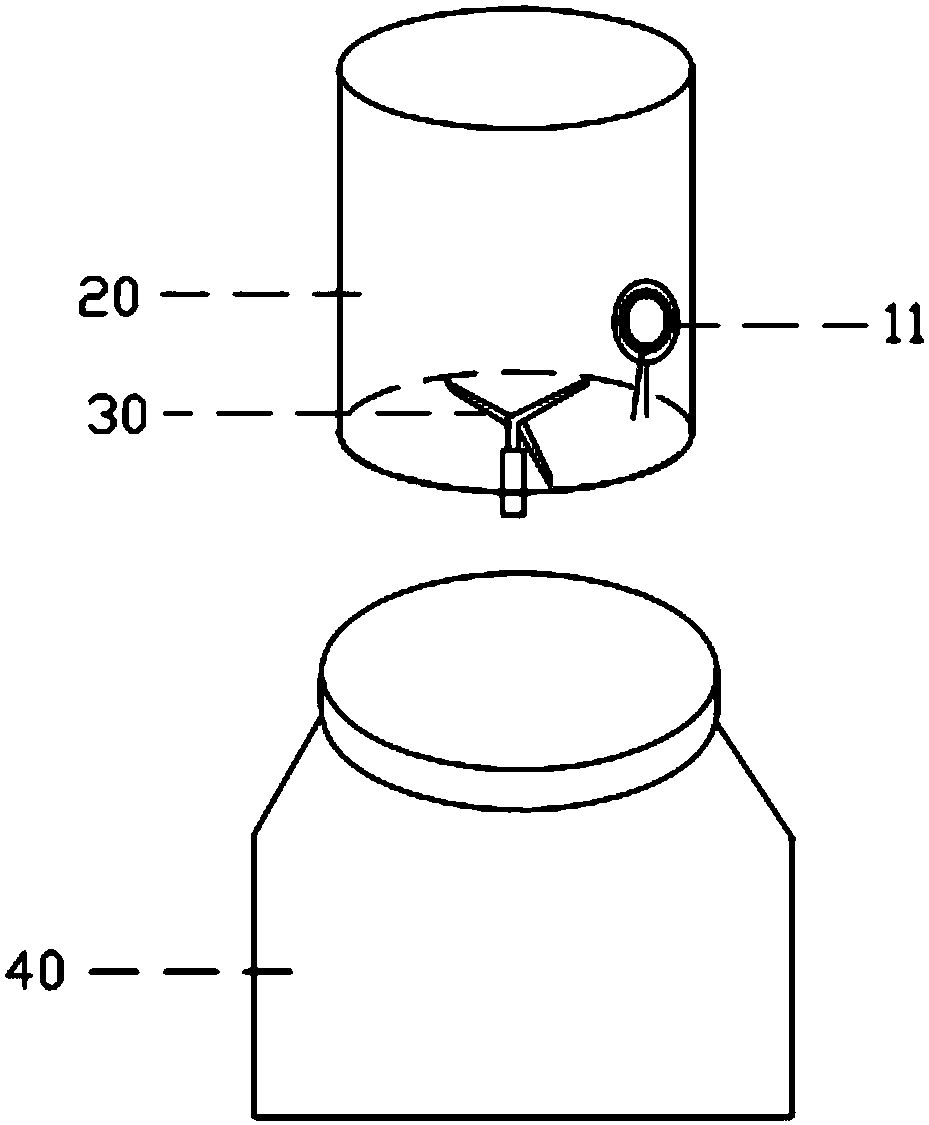

[0044] The detection system provided in the embodiment of the present invention is applied to stirring products. The difference between it and Embodiment 1 is that the stirring product includes a cup body 20. It should be understood that the cup body 20 is a container for holding objects to be stirred. Its own shape, material, etc. are not limited in any way. In the embodiment of the present invention, the induction device includes at least one induction coil 10 , and the induction coil 10 is wound on the above-mentioned cup body 20 .

[0045] In the embodiment of the present invention, the winding position of the induction coil 10 can be the inner wall, the outer wall or the bottom of the cup body 20. In a preferred embodiment, the induction coil 10 is arranged on the cup body for safety or cleaning convenience. 20 of the outer wall. Wherein, the winding manner of the induction coil 10 may be to surround the entire cup body 20, or may be wound sideways at any position on the...

Embodiment 3

[0058] An embodiment of the present invention provides a blender, including a cutter 30 , a cup body 20 , a base 40 ; and any detection system as described in Embodiments 1-2, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com