Method for reducing COD (Chemical Oxygen Demand) and total salt in wastewater in azo pigment preparation

An azo pigment and wastewater technology, applied in azo dyes, monoazo dyes, chemical instruments and methods, etc., can solve the problems of secondary pollution, unrecoverable catalysts, selective oxidation, etc., and achieve good brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

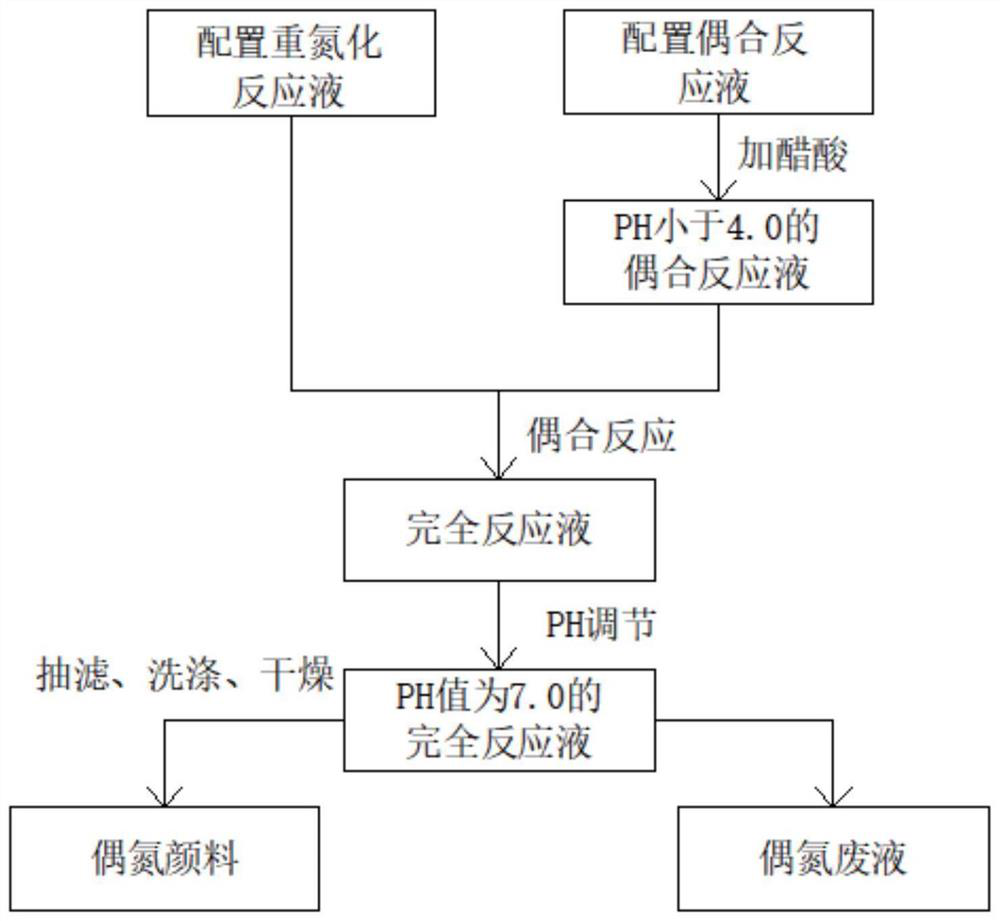

Problems solved by technology

Method used

Image

Examples

Embodiment 1

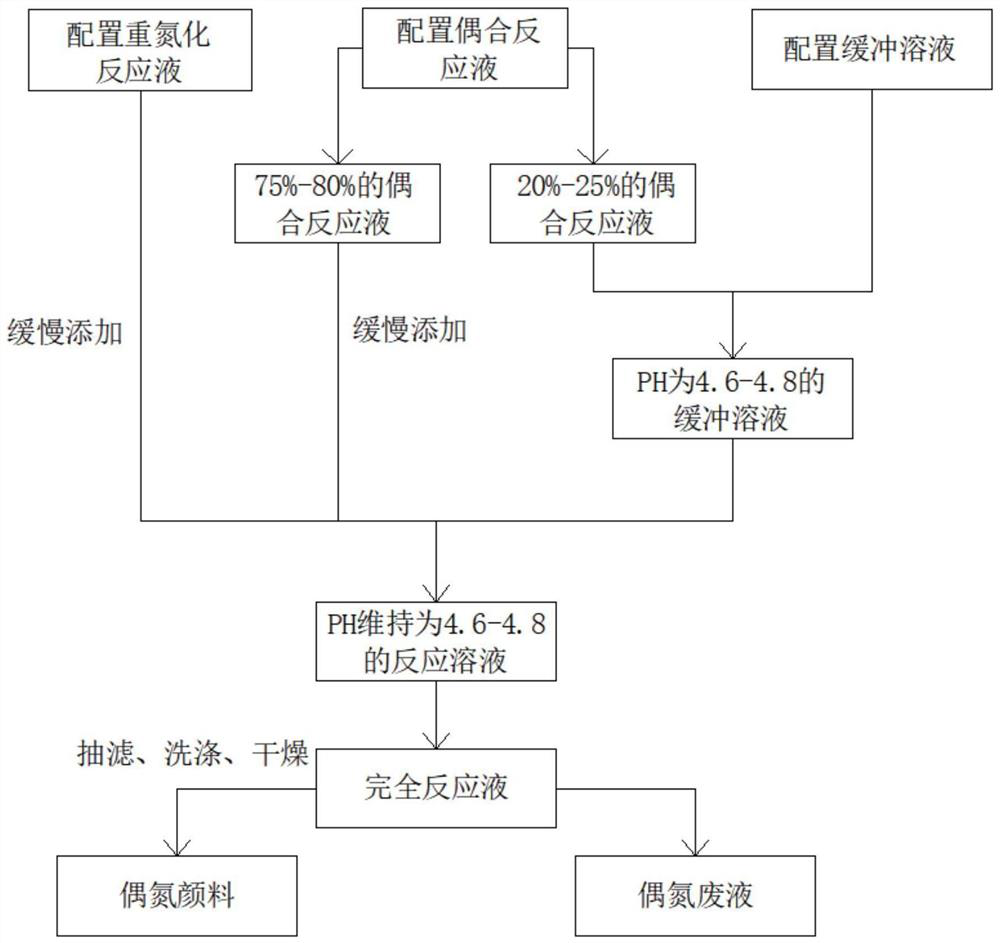

[0024] The present invention provides an embodiment: a method for reducing wastewater COD and total salt during the preparation of azo pigments, the preparation steps of which are as follows:

[0025] Step 1, diazotization: Add 12kg of industrial water to a 30L reaction vessel with temperature control and stirring functions, control the temperature of the industrial water to 2°C, then add 0.93kg of aniline and Stir, and when the diazotization reactant is completely dissolved, slowly add 3 kg of sodium nitrite aqueous solution with a mass concentration of 20% to the interior at 2° C., and react for 30 minutes to obtain 15.93 kg of diazotization reaction liquid;

[0026] Step 2, coupling: add 2.5kg of sodium hydroxide solution and 10kg of industrial water with a mass concentration of 10% to a reaction vessel with a volume of 30L and a temperature control and stirring function, and then add 3.07kg of color For phenol AS-VL, start stirring and heat to 60°C. After the naphthol AS-V...

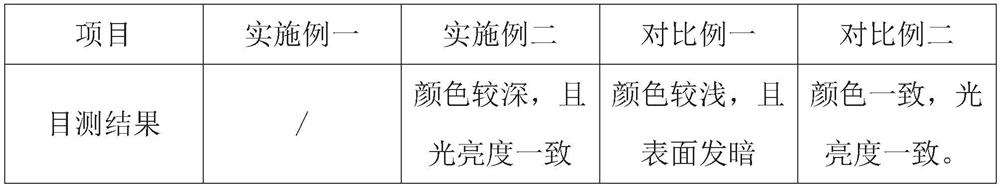

Embodiment 2

[0031] The operation steps are the same as those in Example 1, except that the pH value of the buffer solution is adjusted and maintained at 4.8 in step 4, and finally 3.1 kg of organic pigments and 37.9 kg of azo pigment preparation waste liquid are obtained in step 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com