Silver-loaded floating beads, and preparation and application of silver-loaded floating beads in adsorption of reduced elemental mercury in desulfurization slurry

A floating bead and silver-carrying technology, which is used in adsorption water/sewage treatment, other chemical processes, gaseous discharge wastewater treatment, etc., to achieve good wear resistance, improved mercury removal efficiency, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

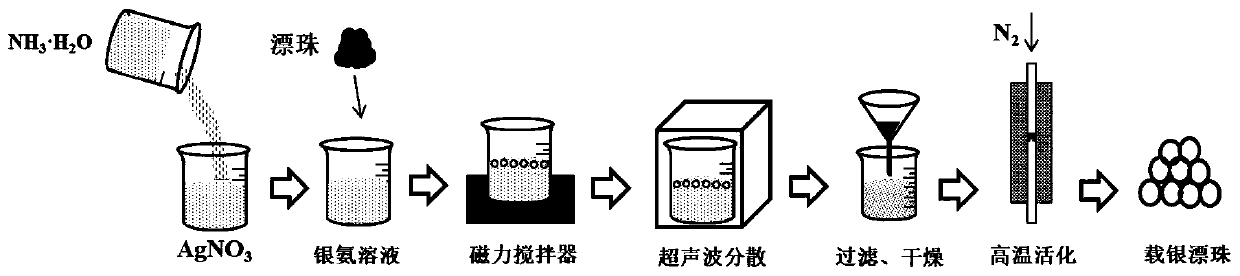

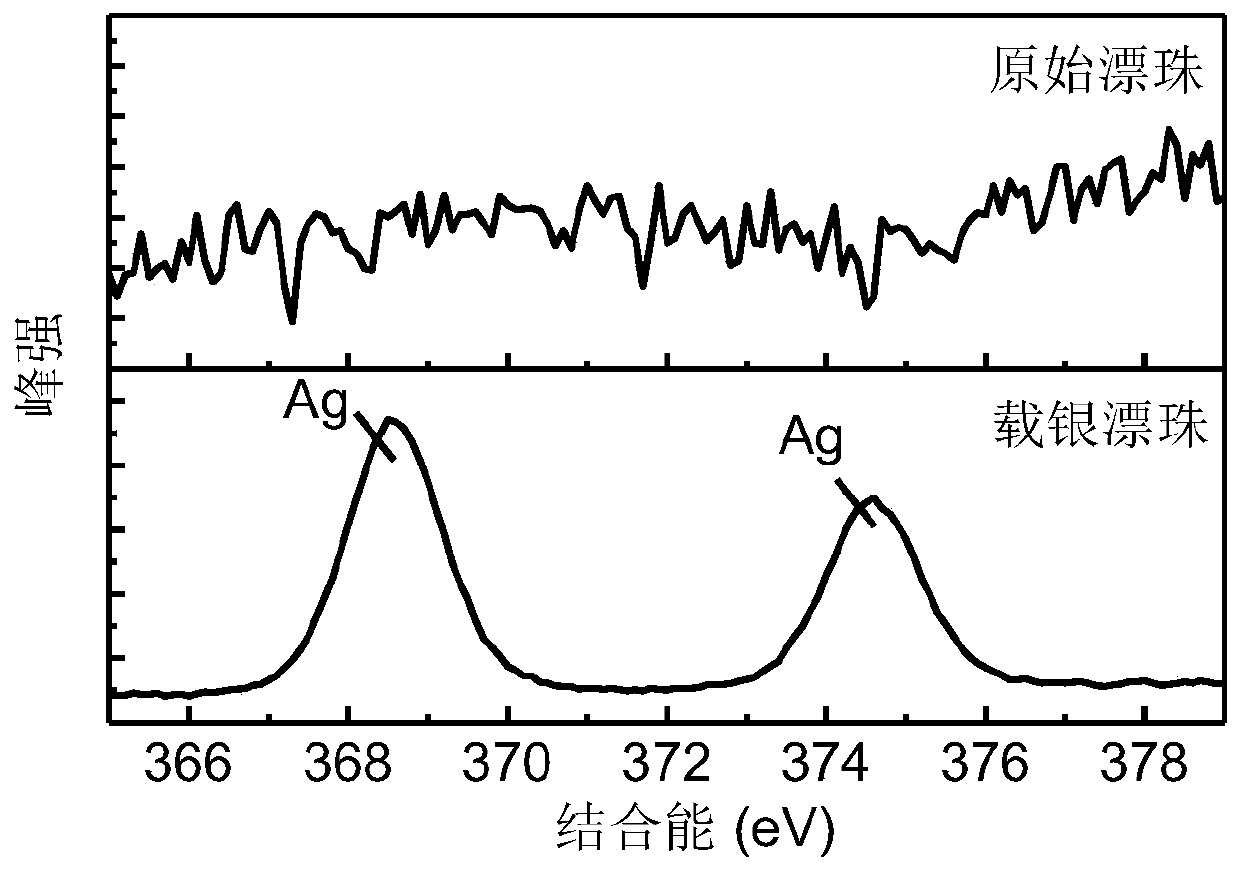

[0043] (1) the silver nitrate of 17g is dissolved in 18.46ml concentration and is the ammoniacal liquor of 20wt%, is settled to 100ml, forms silver ammonia solution;

[0044] (2) add 40g floating pearls in the silver ammonia solution of described step (1), and stir with the speed of 70r / min;

[0045] (3) ultrasonically treating the stirred mixed solution in the step (2) for 3 hours, and drying at 100° C. for 1 hour;

[0046](4) Activate the dried silver-ammonia solution-loaded floating beads in the step (3) at 250° C. for 5 hours under an Ar atmosphere to obtain a silver-loaded floating beads A that inhibits the re-release of mercury in the wet flue gas desulfurization process .

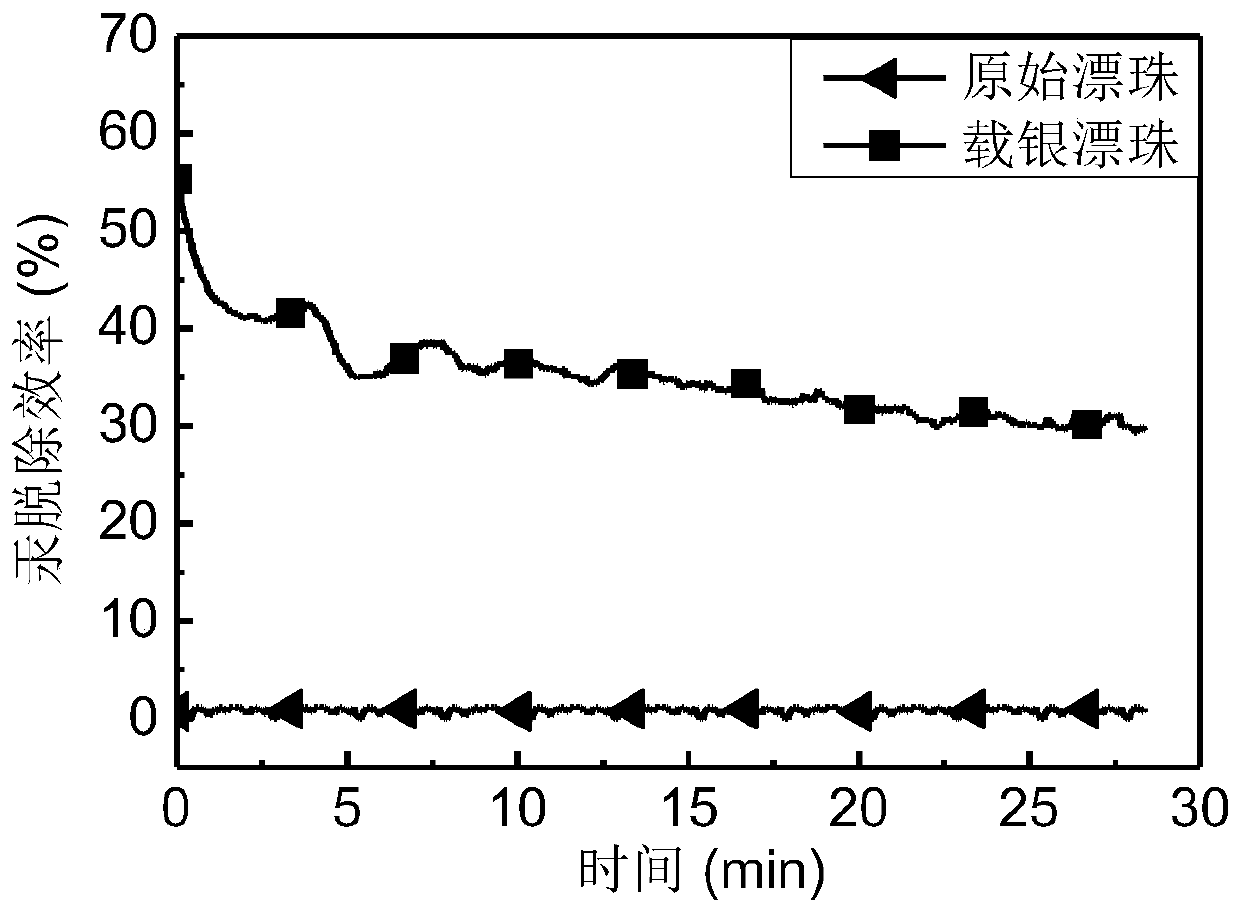

[0047] (5) The mercury adsorption performance test experiment was performed on the floating beads loaded with elemental silver after high temperature activation in the step (4), the initial mercury concentration was 50 μg / m 3 , the amount of adsorbent is 30mg, the adsorption temperature is 140°C, a...

Embodiment 2

[0049] (1) the silver carbonate of 16.56g is dissolved in 43.68ml concentration and is the ammoniacal liquor of 20wt%, is settled to 100ml, forms silver-ammonia solution;

[0050] (2) add 40g floating beads in the silver ammonia solution of described step (1), and stir with the speed of 300r / min;

[0051] (3) ultrasonically treating the stirred mixed solution in the step (2) for 2 hours, and drying at 100° C. for 1 hour;

[0052] (4) the floating beads of the loaded silver ammonia solution dried in the step (3) in N 2 Activated at 350°C for 5 hours in the atmosphere to obtain a silver-loaded floating bead B that inhibits the re-release of mercury in the wet flue gas desulfurization process.

[0053] (5) The mercury adsorption performance test experiment was performed on the floating beads loaded with elemental silver after high temperature activation in the step (4), the initial mercury concentration was 50 μg / m 3 , the amount of adsorbent is 30mg, the adsorption temperature...

Embodiment 3

[0055] (1) the silver nitrate of 8.5g is dissolved in 9.23ml concentration and is the ammoniacal liquor of 20wt%, is settled to 100ml, forms silver-ammonia solution;

[0056] (2) add 40g floating beads in the silver ammonia solution of described step (1), and stir with the speed of 100r / min;

[0057] (3) ultrasonically treat the stirred mixed solution in the step (2) for 5 hours, and dry at 110° C. for 1 hour;

[0058] (4) the floating beads of the loaded silver ammonia solution dried in the step (3) in N 2 Activated at 200°C for 5 hours in the atmosphere to obtain a silver-loaded floating bead C that inhibits the re-release of mercury during the wet flue gas desulfurization process.

[0059] (5) The floating beads loaded with elemental silver after high-temperature activation in the step (4) were subjected to a mercury adsorption performance test experiment, and the initial mercury concentration was 40 μg / m 3 , the amount of adsorbent is 30mg, the adsorption temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com