Oil-immersed transformer cooling control method based on temperature rise and load rate

An oil-immersed transformer, cooling control technology, applied in the direction of transformer/inductor cooling, temperature control, non-electric variable control, etc., can solve the threat of the service life and safety and reliability of the cooling system, cannot accurately reflect the operating state of the transformer, and is inconvenient Refined management and energy saving, etc., to achieve the effect of facilitating refined management, avoiding frequent switching, and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

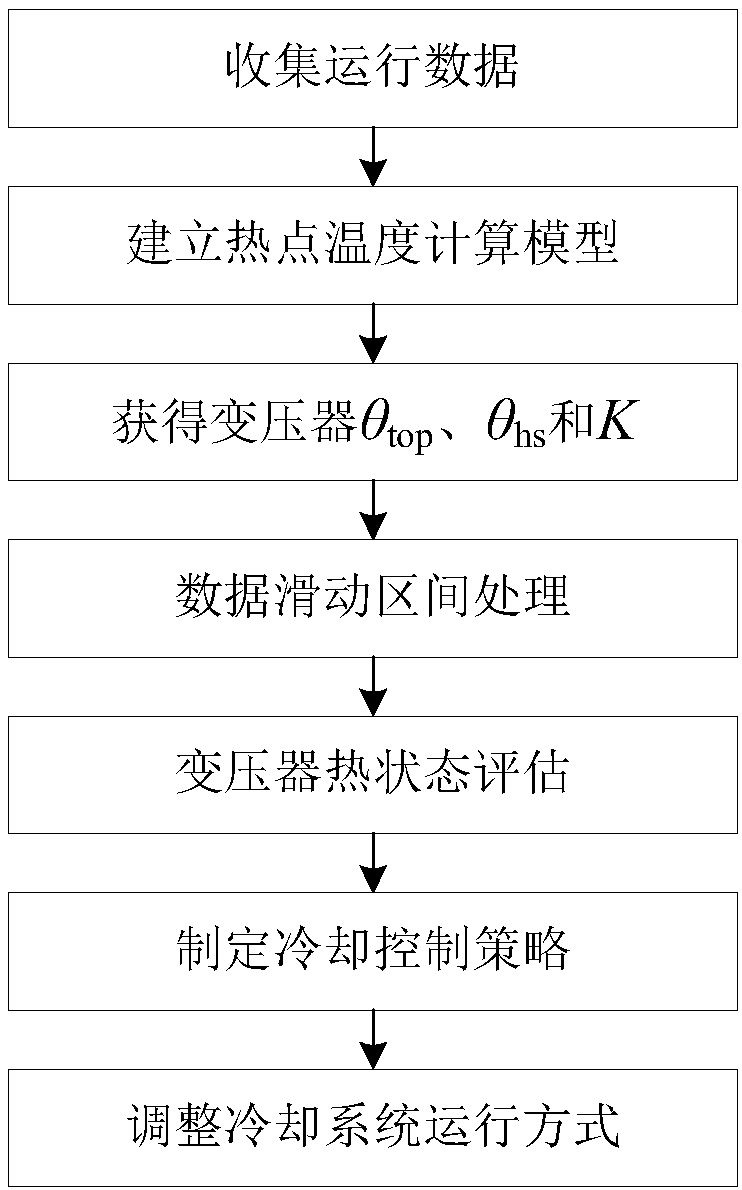

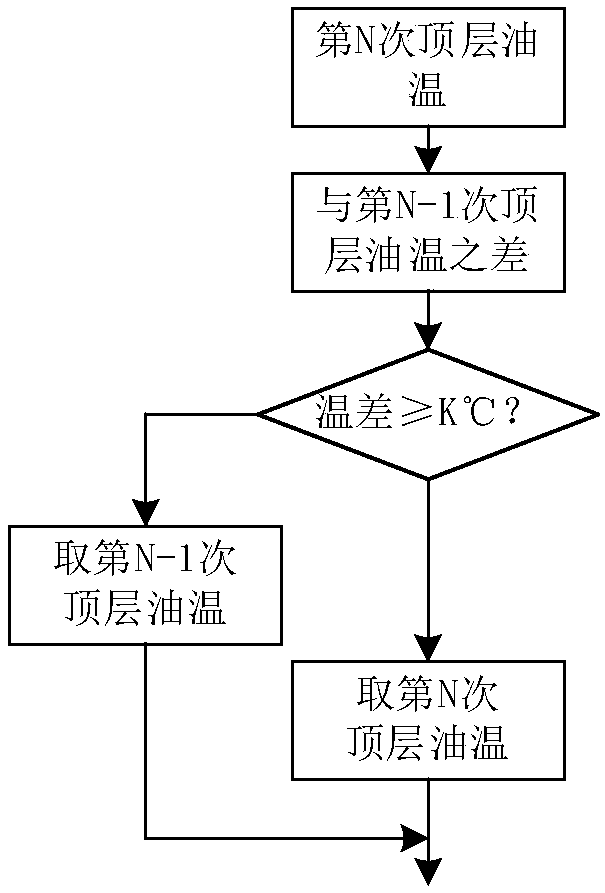

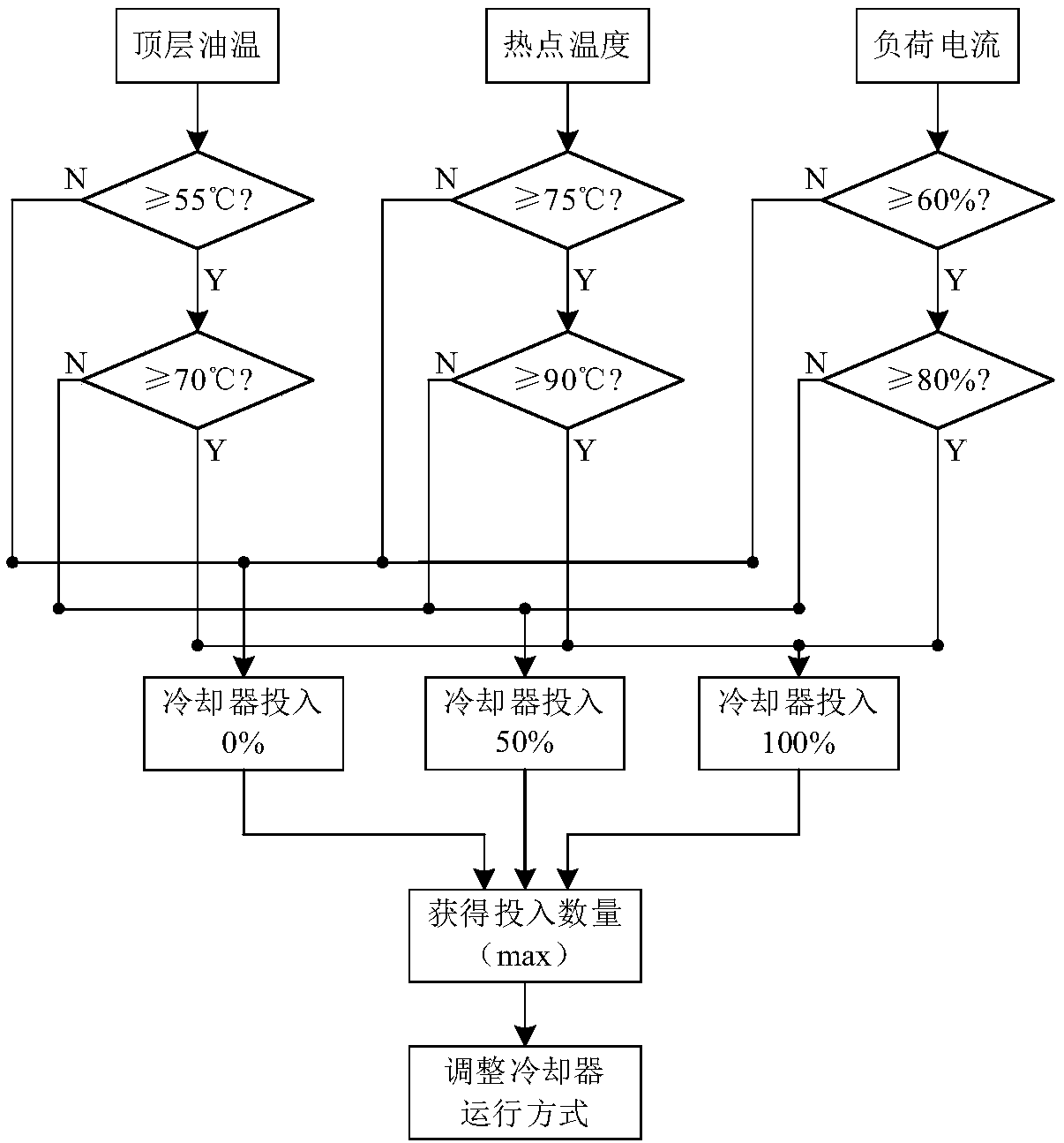

[0018] The cooling system plays a very important role in the operation of the transformer. It is an important guarantee for the timely transfer of heat inside the transformer. Its working status is directly related to the safe and reliable operation of the transformer. The oil temperature on the top layer of the transformer and the hot spot temperature can directly represent its thermal state, but when the load changes, the internal temperature of the transformer does not change suddenly, but changes slowly over a period of time, which cannot reflect the thermal state of the transformer in time. Therefore, the embodiment of the present invention comprehensively evaluates the heat dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com