Cooling molding device for metal melt applied to fuse

A metal melt, cooling forming technology, applied in the field of electric power, can solve the problems of insufficient fineness, backward equipment, not perfect, etc., and achieve the effect of comprehensive and rapid cooling, adjustable cooling space, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments are given below to further illustrate the technical solutions of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment based on the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

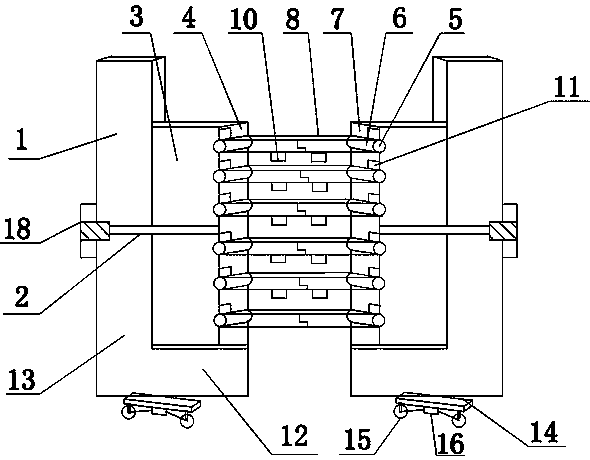

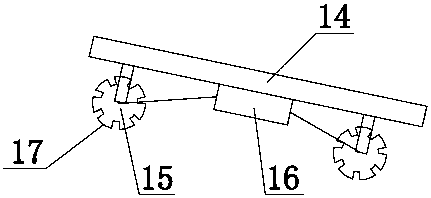

[0026] like Figure 1-2 As shown, a cooling and forming device for a metal melt for a fuse comprises two opposite L-shaped bases 1, a cooling mechanism arranged between the L-shaped bases 1, and a motion mechanism arranged at the bottom end of the L-shaped base 1;

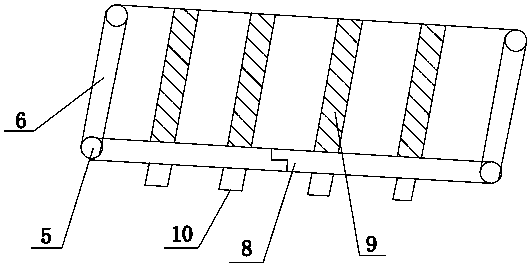

[0027] The cooling mechanism includes a push-pull plate 3 arranged on the inner side of the L-shaped base 1 through a thrust shaft 2. The push-pull plate 3 is relatively parallel and arranged with a gap, so that the width of the telescopic plate 8 can be adjusted according to different use requirements, so as to achieve The cooling space is adjustable; the opposing push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com