Cement production material crushing, batching and mixing device

A material crushing and mixing device technology, applied in the field of cement, can solve the problems affecting the production, storage, transportation and use of cement, and achieve the effect of complete functions, low production cost and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

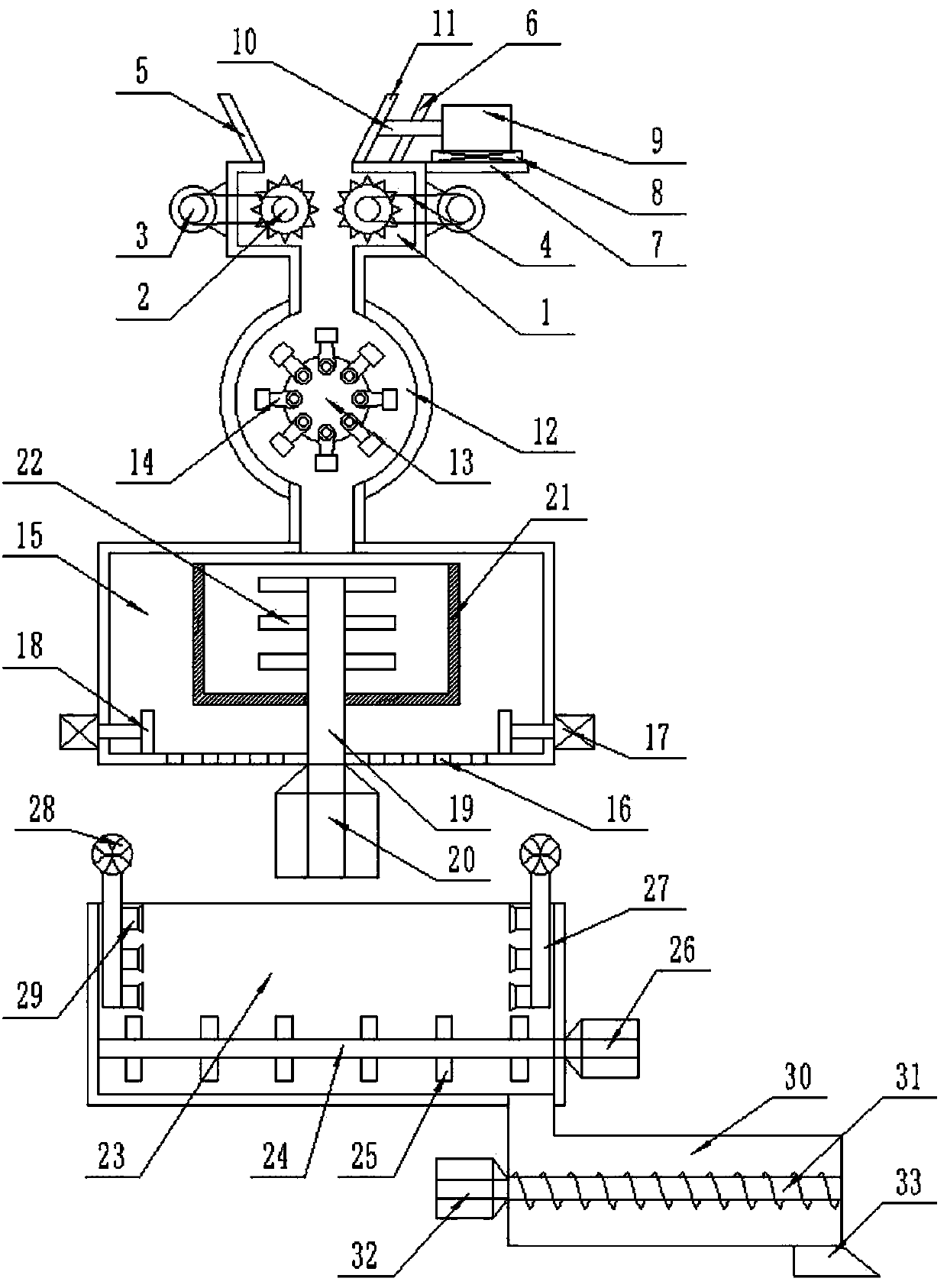

[0013] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a crushing and batching mixing device for cement production materials, including a rolling chamber 1, a rolling wheel 2, a driving motor 3, a belt 4, a left opening plate 5, a right opening plate 6, Platform 7, buffer pad 8, air pressure rod 9, push rod 10, movable opening plate 11, crushing chamber 12, crushing roller 13, crushing hammer 14, crushing chamber 15, discharge hole 16, pushing air pressure rod 17, pushing plate 18 , rotating shaft 19, crushing motor 20, centrifugal net 21, crushing blade 22, mixing chamber 23, mixing shaft 24, mixing rod 25, mixing motor 26, air duct 27, exhaust fan 28 and tuyere 29; A left opening plate 5 is fixedly connected to the left side of the upper surface; a right opening plate 6 is fixedly connected to the right side of the upper surface of the rolling chamber 1; a platform is fixedly connected to the outer upper end of the right side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com