Surface spraying device for composite door manufacturing

A technology for surface spraying and compound doors, which is applied in spraying devices, spray booths, etc., can solve the problems of difficulty in meeting the simultaneous spraying of compound doors, affecting the use effect of compound doors, affecting production efficiency, and the quality of compound doors, so as to reduce injuries to workers. , the effect of complete functions and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

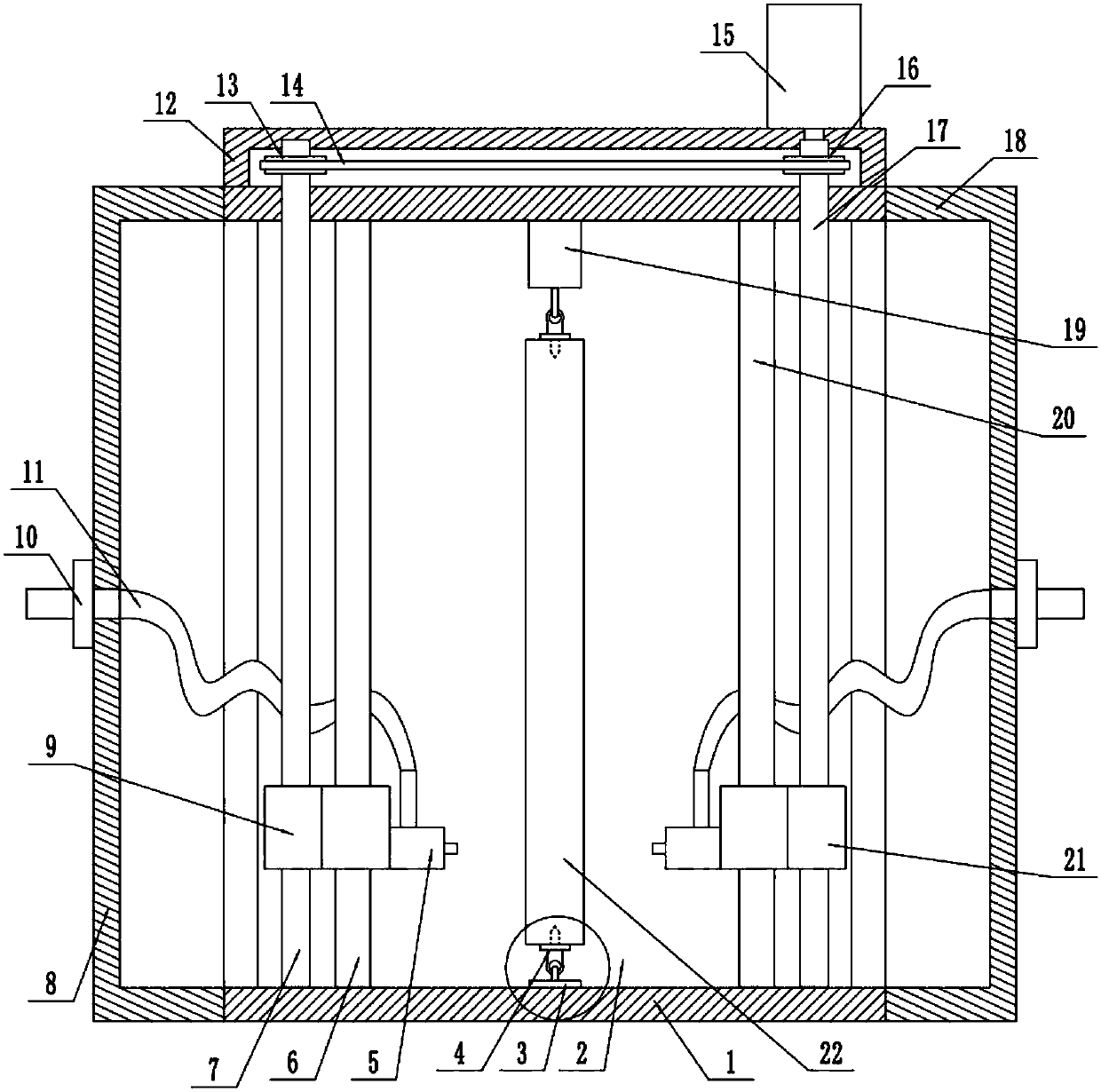

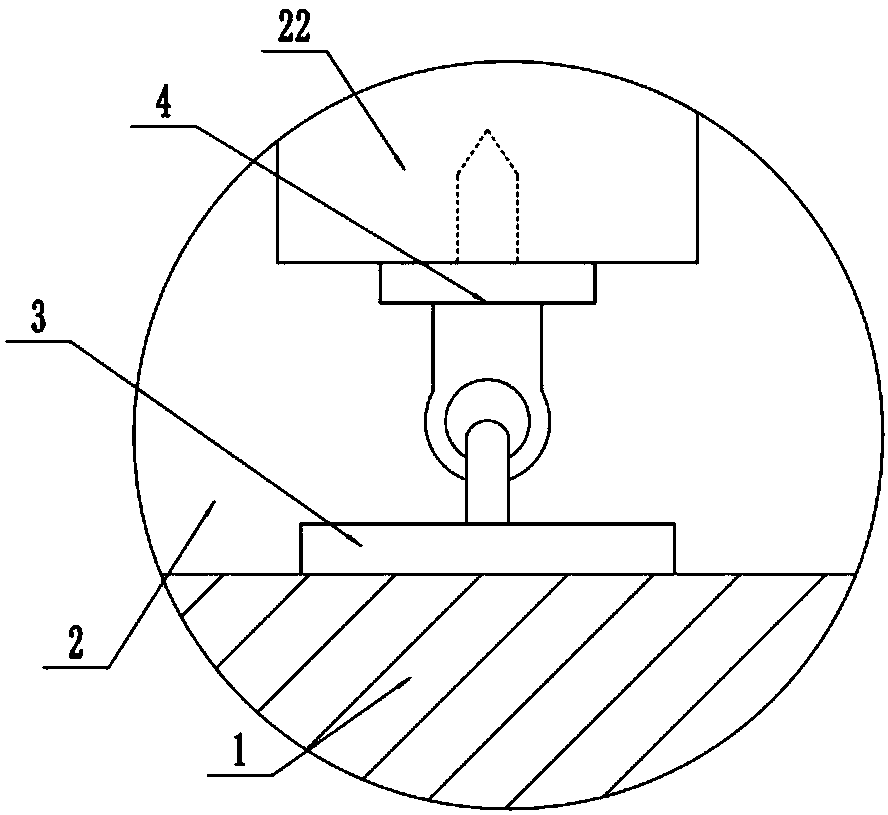

[0013] Such as figure 1 and figure 2 As shown, this specific embodiment adopts the following technical solutions: a surface spraying device for composite door manufacturing, including a spraying nozzle 5 and a composite door body 22, and also includes a spraying box 1, a spraying room 2, a lower fixing hook 3, and a pull ring 4. Guide post-6, screw-7, side housing-8, movable seat-9, connector 10, hose 11, upper housing 12, driven pulley 13, belt 14, motor 15, driving pulley 16. Screw two 17, side shell two 18, upper fixed hook 19, guide post two 20 and movable seat two 21; the inside of the spraying box 1 is provided with a spraying room 2, and the left and right sides of the spraying box 1 are respectively There are side casing one 8 and side casing two 18 fixedly connected, and the upper casing 12 is fixedly connected on the top surface of the spraying box body 1; Lower fixed hook 3; said pull ring 4 is several, and said pull ring 4 is respectively fixedly connected on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com