Split type ceramic shell assembly and molding process for precision casting

A technology of ceramic mold shell and precision casting, which is applied in casting molding equipment, mold, mold composition, etc. Easy quality assurance, simple assembly process, high molding efficiency and high quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

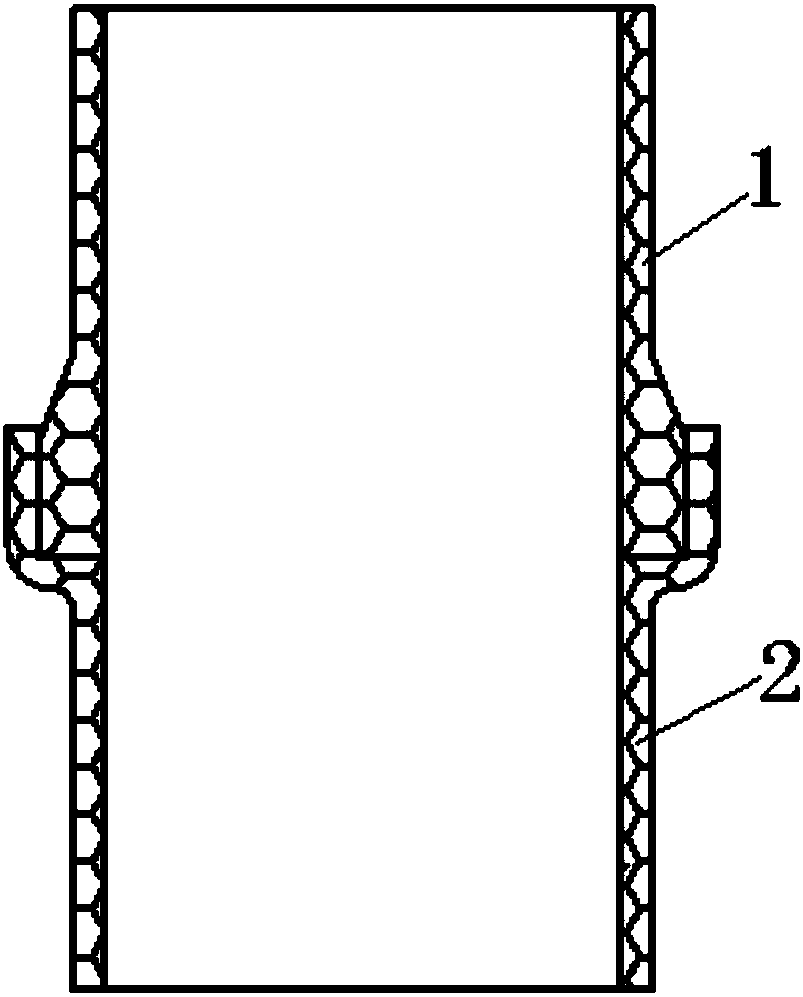

[0030] The present invention is the split-type ceramic formwork assembly molding technique that precision casting is used, and it comprises following technical measures:

[0031] Step 1. According to the design structure of the corresponding casting and / or the technical requirements of the casting process, the corresponding ceramic formwork is designed as two independent ceramic formwork halves, and there should be a gap between the two ceramic formwork halves. Corresponding and matching joints, their joints are formed with a concave and convex joint structure, that is, one half of the ceramic formwork is a concave joint structure, and the other half of the ceramic formwork is a matching convex joint. Type stop structure;

[0032] In addition, in order to facilitate assembly and package the structural strength after assembly, when the ceramic formwork is designed separately, the corresponding concave and convex joints between the two ceramic formwork halves should be at the ce...

Embodiment 2

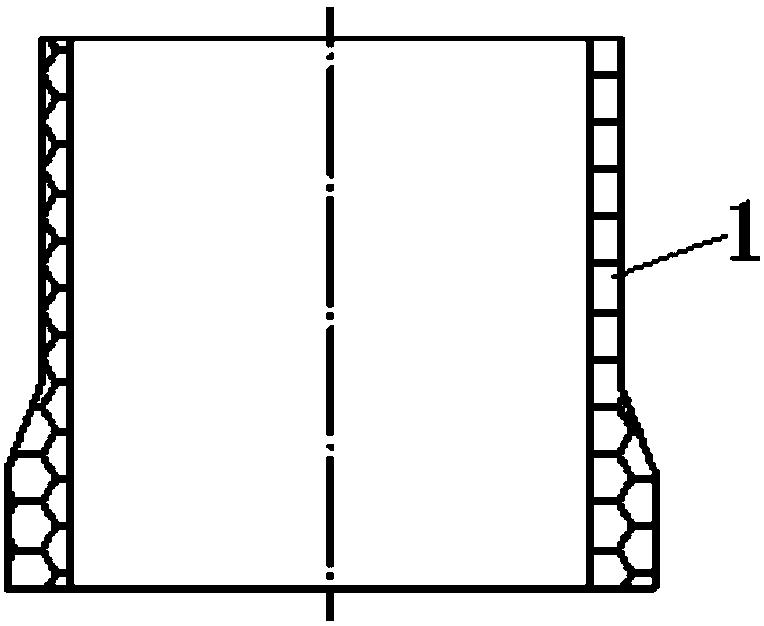

[0045] The present invention is the split-type ceramic formwork assembly molding technique that precision casting is used, and it comprises following technical measures:

[0046] Step 1. According to the design structure of the corresponding casting and / or the technical requirements of the casting process, the corresponding ceramic formwork is designed as three independent ceramic formwork halves, and there should be a gap between the three ceramic formwork halves. Corresponding and matching joints, their corresponding joints are formed with a concave and convex matching seam structure;

[0047] In addition, in order to facilitate the assembly and package the structural strength after assembly, when the ceramic formwork is designed separately, the corresponding concave and convex joints between the three ceramic formwork halves should be located in the entire ceramic formwork. On the sprue, that is to say, when designing, the disassembly of the entire ceramic formwork is taken...

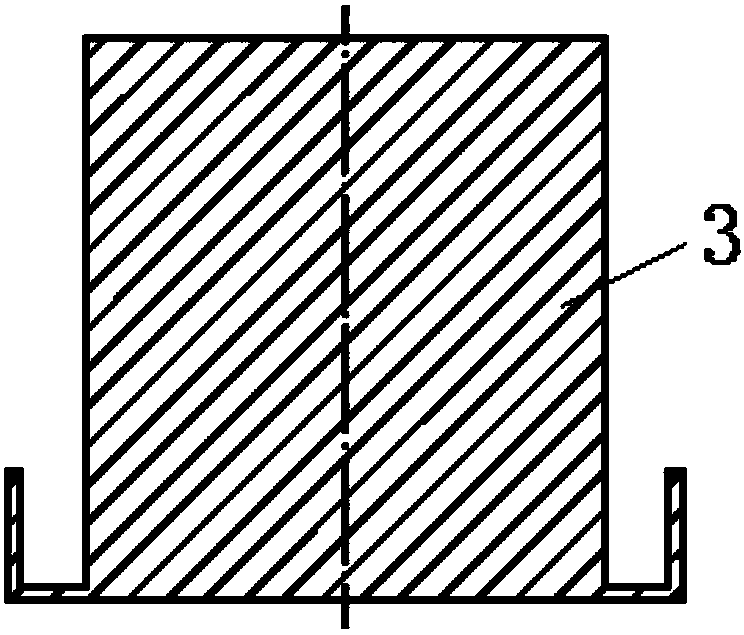

Embodiment 3

[0059] The other content of this embodiment is the same as that of Embodiment 2, except that there are four ceramic formwork halves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com