Drilling-free forming pile based on radial pressurization and construction method and application thereof

A drilling-free and pile-free technology, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems that the surrounding soil cannot provide radial pressure, the quality of hole formation is high, and the construction period is long. The effect of increasing drainage consolidation efficiency, low construction cost, and low input cost

Inactive Publication Date: 2013-02-27

李晓军

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Cast-in-situ piles have the advantages of no vibration, no soil extrusion, low noise during construction, and are suitable for use in urban areas with dense buildings. Defects and deficiencies such as relatively long construction period

In addition, the functions of the prefabricated piles and cast-in-situ piles used today are relatively single, and the pile body cannot provide radial pressure to the surrounding soil during and after the construction of the pile body.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0044] In this embodiment, the adopted drilling-free formed pile and its construction method are the same as those in Embodiment 1.

[0045] In this embodiment, the difference from Embodiment 1 is that the number of piles formed in step 3 is multiple, and the plurality of piles form a seepage-proof wall.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

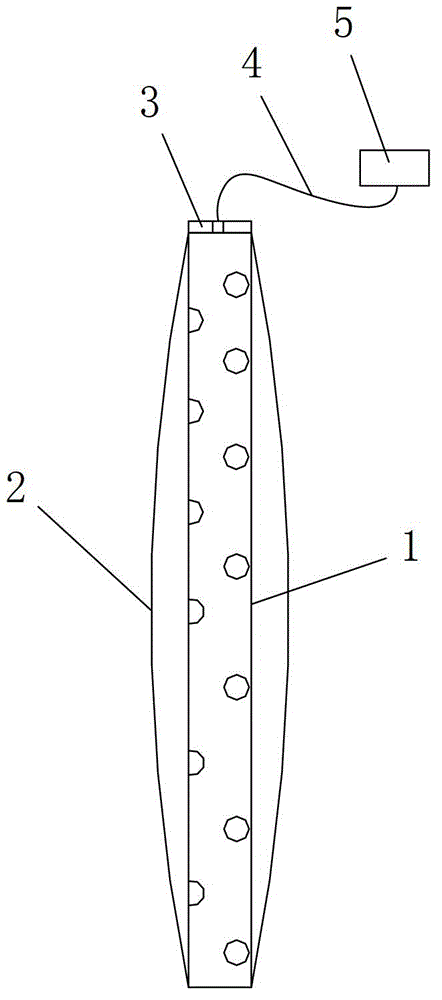

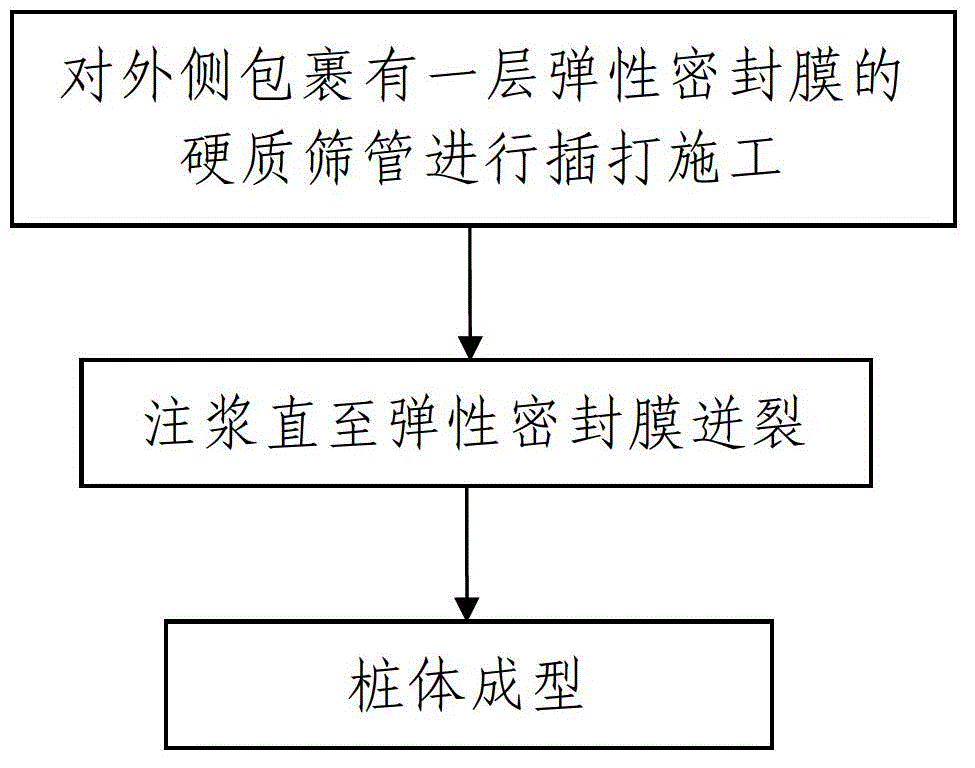

The invention discloses a drilling-free forming pile based on radial pressurization and a construction method and application thereof. The drilling-free forming pile comprises a pile body, the pile body is formed through that slurry is continuously filled in a hard screen pipe wrapped by one layer of elastic sealing film until the elastic sealing film is burst open and the filled slurry enters a peripheral soil layer, the filled slurry is cement mortar or concrete, the hard screen pipe is a pipe body is inserted in the soil layer in advance, and a plurality of slurry filling holes are arranged on the side wall of the hard screen pipe. The construction method includes: 1, hard screen pipe inserting; 2, slurry filling; and 3, pile body forming. The formed pile body is an anti-sliding pile for stabilizing side slopes or a reinforcing pile for reinforcing a foundation, and a plurality of formed pile bodies form an anti-seepage wall. The drilling-free forming pile is reasonable in structural design, convenient to construct, low in investment cost, good in using effect, high in practical value, wide in application range and capable of solving the problems of inconvenient construction, high investment cost, long construction period, poor using effect and the like of an existing pile foundation.

Description

technical field [0001] The invention belongs to the technical field of pile body construction, and in particular relates to a drilling-free formed pile based on radial pressure and its construction method and application. Background technique [0002] Nowadays, the pile foundations used in the field of civil engineering are mainly divided into prefabricated piles and cast-in-situ piles according to the construction method. Among them, prefabricated piles are made of various materials and various forms of piles (such as wooden piles, concrete square piles, prestressed concrete pipe piles, steel piles, etc.) Drive, press or vibrate into the soil. At present, the prefabricated piles that are widely used are mainly concrete prefabricated piles and steel piles. In actual construction, due to the heavy weight of the prefabricated pile itself, and the use of pile driving equipment to drive, press or vibrate into the soil, there are various degrees of inconvenience in construction...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E02D5/36

Inventor 李晓军李来宾

Owner 李晓军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com