Elastic support device of plate shearer

A telescopic support and shearing machine technology, applied in shearing devices, accessories of shearing machines, shearing machine equipment, etc., can solve the problems of small size and laborious operation, improve efficiency, simple and labor-saving operation, and ensure levelness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

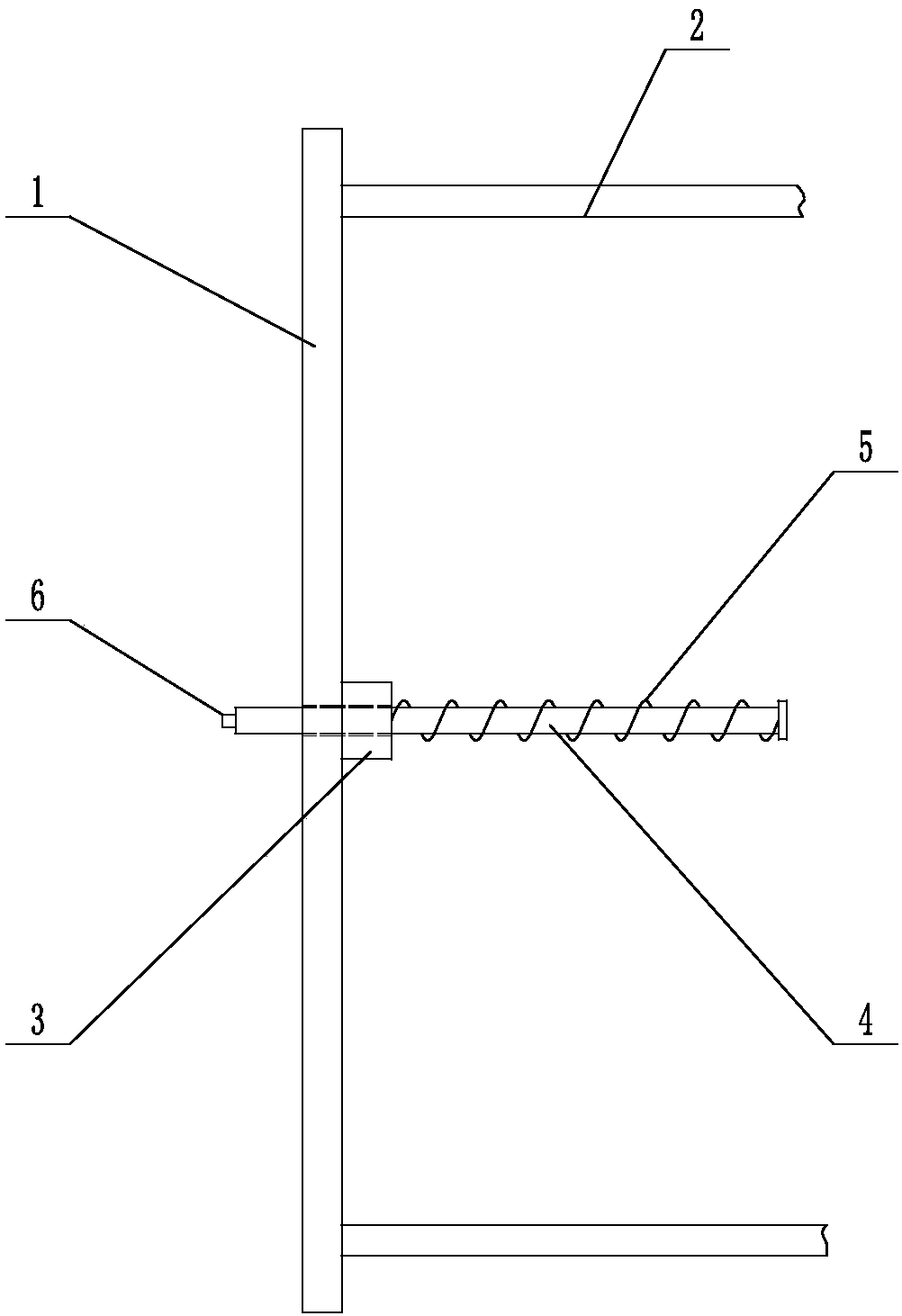

[0012] Such as figure 1 As shown, the right side wall of the baffle plate 1 is provided with a guide column 2, the middle of the right side wall of the baffle plate 1 is provided with a connecting cylinder 3, and the inside of the connecting cylinder 3 is provided with a telescopic rod 4, and the two ends of the telescopic rod 4 extend out respectively. On both sides of the baffle plate 1 and the connecting cylinder 3, the right end of the telescopic rod 4 is connected with the right end of the connecting cylinder 3 through a spring 5, and the left end of the telescopic rod 4 is provided with a supporting block 6. Wherein the telescopic rod 4 and the supporting block 6 are both cylindrical.

[0013] The upper end of the support block 6 is in the same plane as the upper end of the support plate of the shearing machine. At the initial stage of work, the left end of the support block 6 is in contact with the support plate. When the steel plate is inserted into the shearing machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com