Multifunctional rock cutting machine

A cutting machine, multi-functional technology, applied in stone processing equipment, sampling, measuring devices, etc., can solve the problems of inability to cut large rock blocks and irregular rock blocks, inconvenient operation, and narrow operating space, etc., to achieve the largest operating space The effect of streamlining and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings.

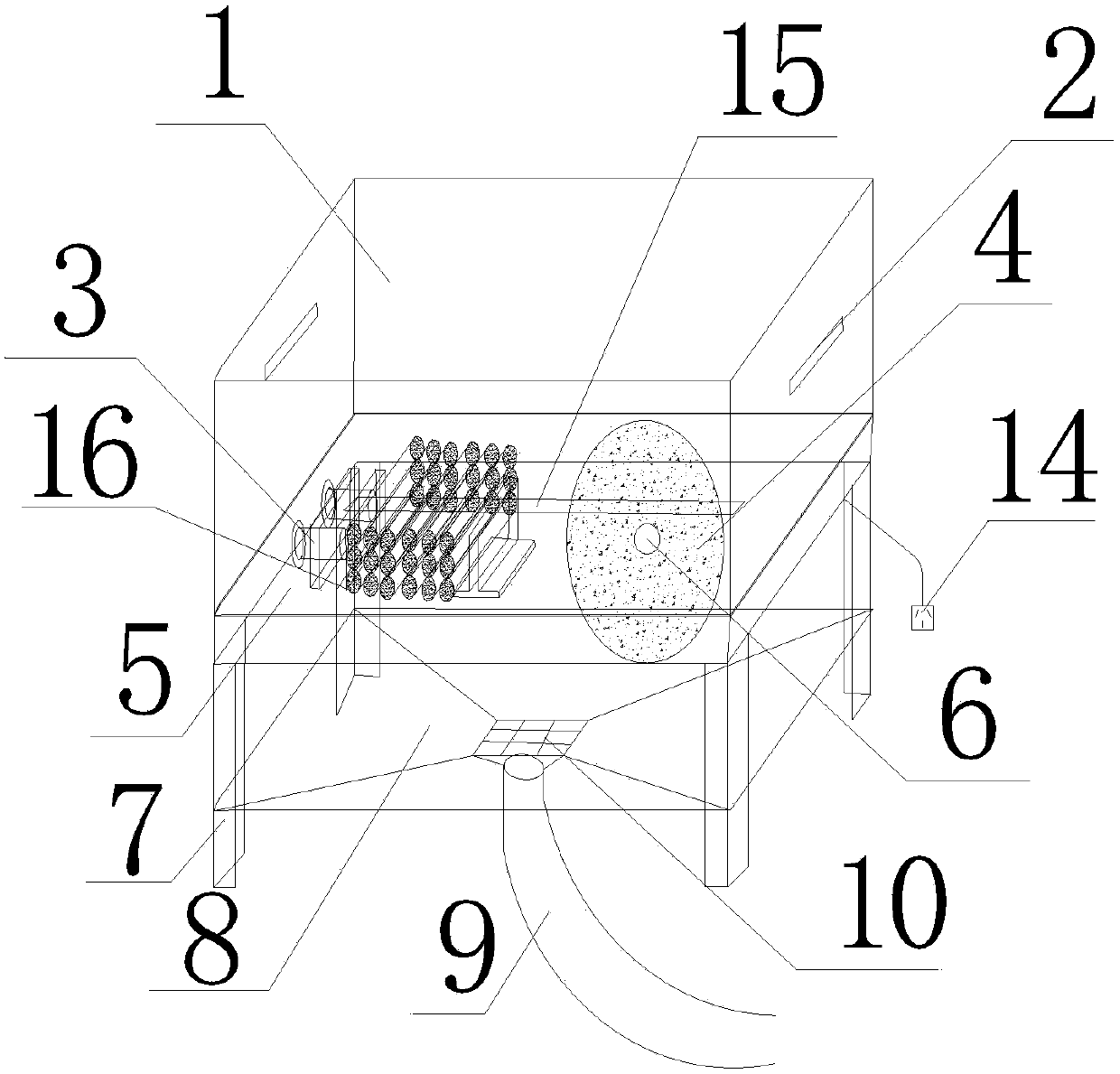

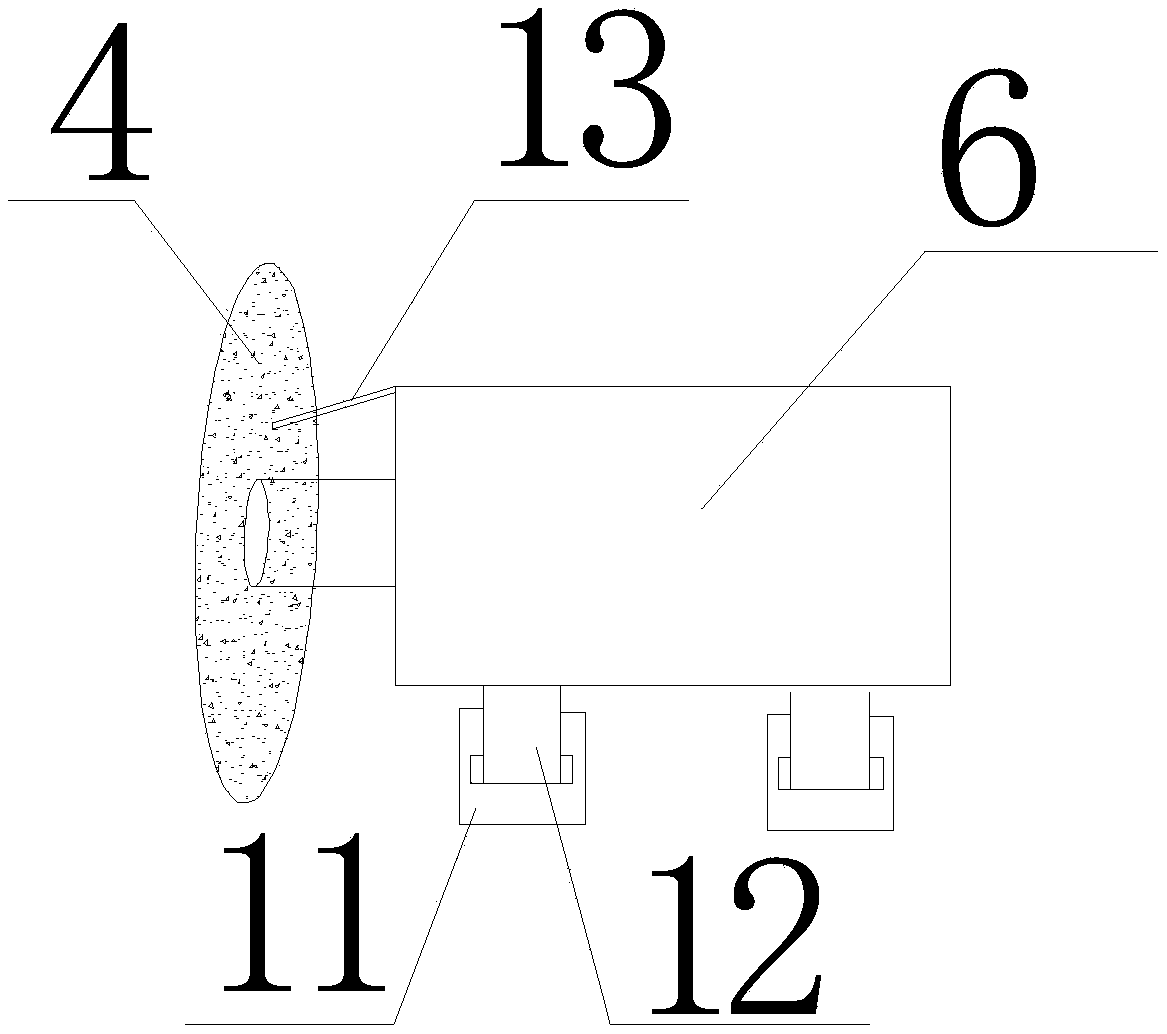

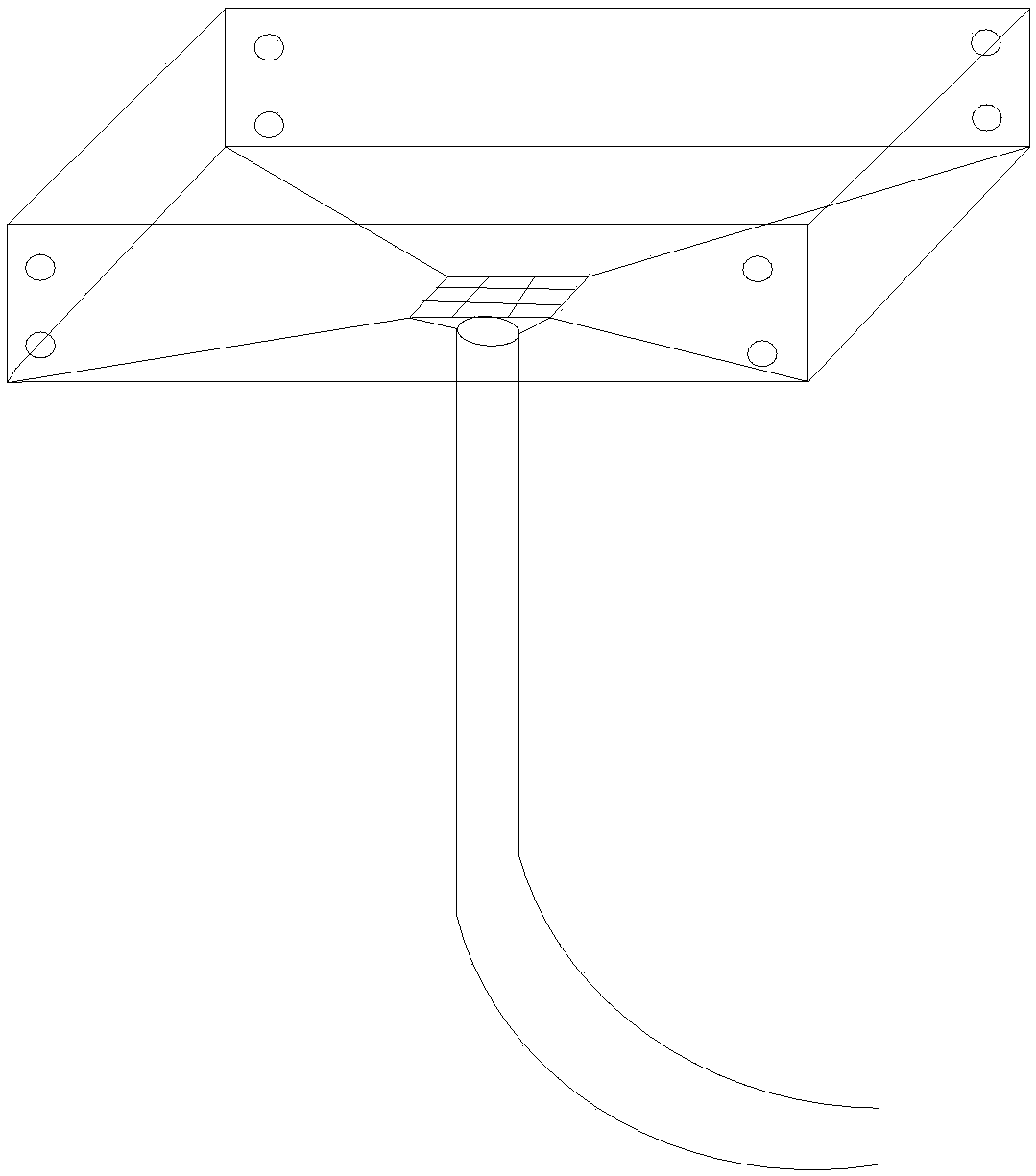

[0018] Such as figure 1 The present invention discloses a kind of multi-functional rock cutting machine as shown, comprises cutting machine upper shield (1), upper shield handle (2), rock specimen fixture (3), cutting machine pedestal (5), cutting cutter head ( 4), motor (6), pedestal leg support (7), mud collection funnel (8), mud drain pipe (9), mud filter (10), motor moving track (11), motor bottom bayonet (12) , the drainage pipe (13) of the cooling cutterhead, the power plug (14), the cutting cutterhead walking gap (15); there is a cutting cutterhead walking gap (15) on the cutting machine pedestal (5), and the cutting cutterhead (4 ) can move forward along the gap to cut the rock specimen (16) along with the movement of the motor (6) on the motor moving track (11). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com