5G mobile phone composite material processing technology

A technology of composite materials and processing technology, which is applied in the field of material processing, can solve the problems of operator's two-handed operation obstruction, low utilization rate of metal materials, and difficulty in secondary powder recovery, so as to save processing operations, excellent appearance effect, and reduce processing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

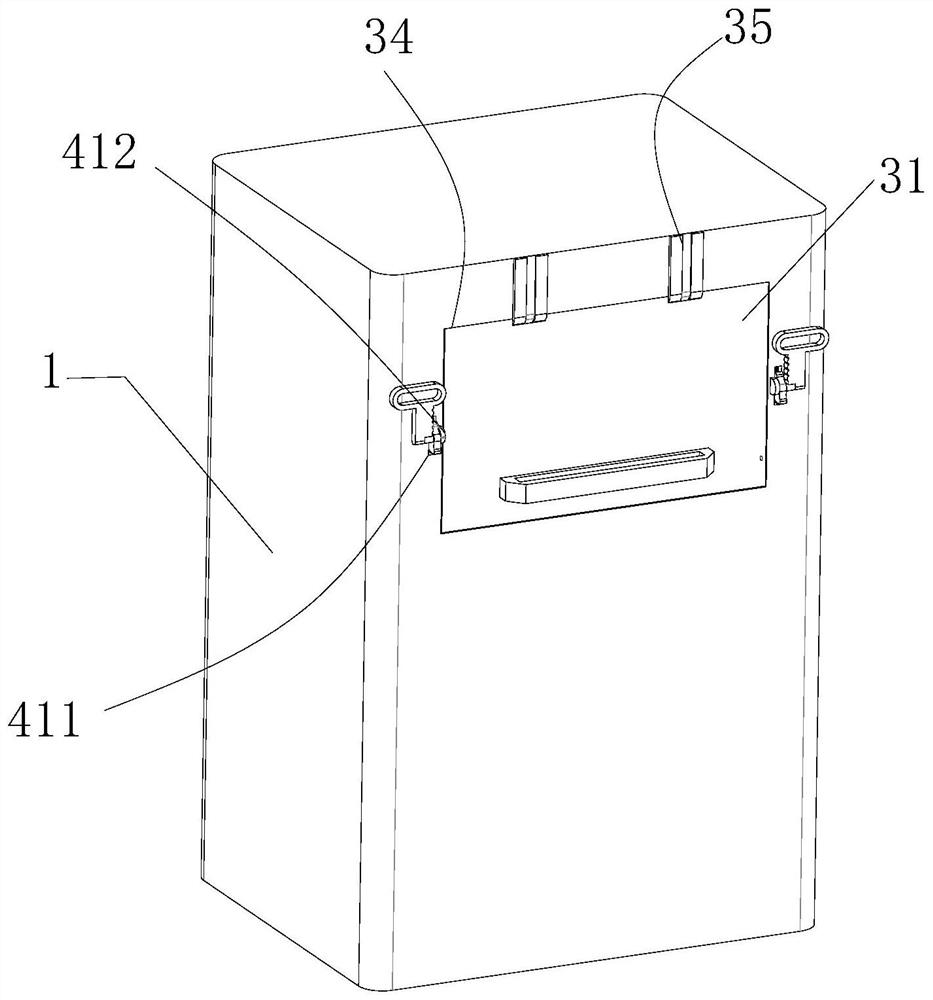

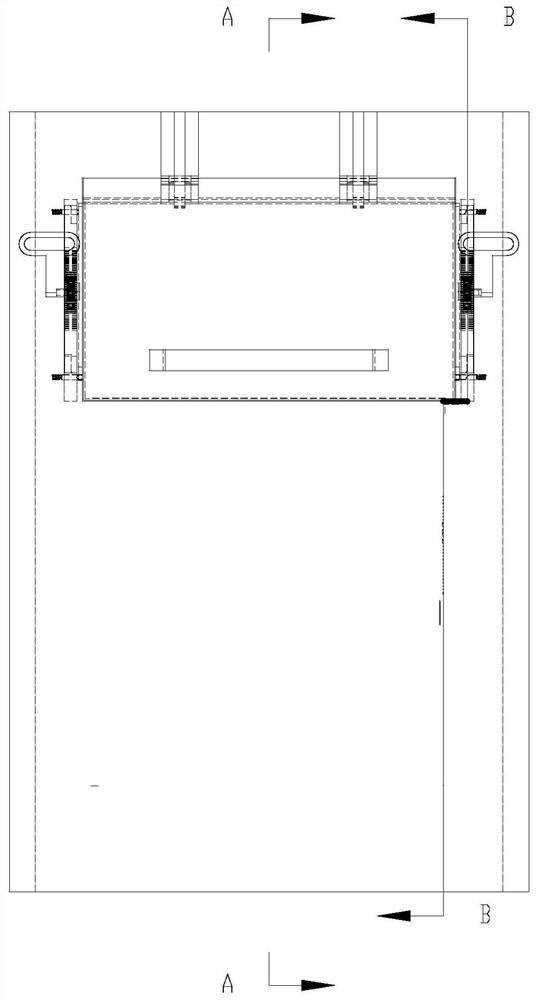

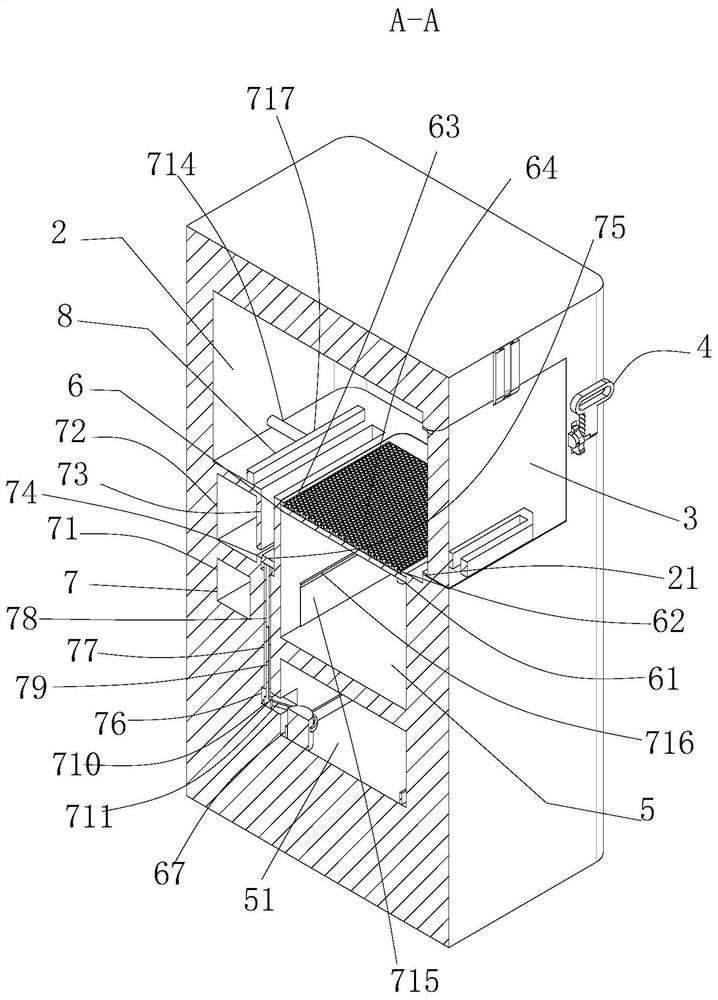

Image

Examples

Embodiment 1

[0028] A 5G mobile phone composite material processing technology, characterized in that: comprising the following steps:

[0029] Step 1: Make a titanium alloy middle frame through a 3D printer;

[0030] Step 2: integrally molding plastic structural parts on the titanium alloy middle frame by injection molding;

[0031] Step 1 includes: using titanium alloy powder to perform 3D laser three-dimensional printing to form a titanium alloy middle frame green body, and then putting the titanium alloy middle frame green body into a vacuum sintering furnace for vacuum annealing to obtain the titanium alloy middle frame; , Put the titanium alloy TC4 mixed metal powder into the powder sieving machine, remove the metal powder particles with a particle size of more than 50 μm, and then put the sieved metal powder into the 3D printer, fill it with argon inert gas, and remove the oxygen in the printer The content is reduced to less than 1.5%, the 3D printer is turned on, and the titanium ...

Embodiment 2

[0042] A 5G mobile phone composite material processing technology, characterized in that: comprising the following steps:

[0043] Step 1: Make a titanium alloy middle frame through a 3D printer;

[0044] Step 2: integrally molding plastic structural parts on the titanium alloy middle frame by injection molding;

[0045] Step 1 includes: using titanium alloy powder to perform 3D laser three-dimensional printing to form a titanium alloy middle frame green body, and then putting the titanium alloy middle frame green body into a vacuum sintering furnace for vacuum annealing to obtain the titanium alloy middle frame; , Put the titanium alloy TC4 mixed metal powder into the powder sieving machine, remove the metal powder particles with a particle size of more than 50 μm, and then put the sieved metal powder into the 3D printer, fill it with argon inert gas, and remove the oxygen in the printer The content is reduced to less than 1.5%, the 3D printer is turned on, and the titanium ...

Embodiment 3

[0050] A 5G mobile phone composite material processing technology, characterized in that: comprising the following steps:

[0051] Step 1: Make a titanium alloy middle frame through a 3D printer;

[0052] Step 2: integrally molding plastic structural parts on the titanium alloy middle frame by injection molding;

[0053] Step 1 includes: using titanium alloy powder to perform 3D laser three-dimensional printing to form a titanium alloy middle frame green body, and then putting the titanium alloy middle frame green body into a vacuum sintering furnace for vacuum annealing to obtain the titanium alloy middle frame; , Put the titanium alloy TC4 mixed metal powder into the powder sieving machine, remove the metal powder particles with a particle size of more than 50 μm, and then put the sieved metal powder into the 3D printer, fill it with argon inert gas, and remove the oxygen in the printer The content is reduced to less than 1.5%, the 3D printer is turned on, and the titanium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com