Six-degree-of-freedom annular tooling and delivery device for the space cabin

A carrier device and degree of freedom technology, applied in the direction of manufacturing tools, program-controlled manipulators, manipulators, etc., can solve the problems of inability to adjust the attitude of parts, small operating space, and large structural space, so as to improve the load capacity of equipment and reduce the overall Good size and force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

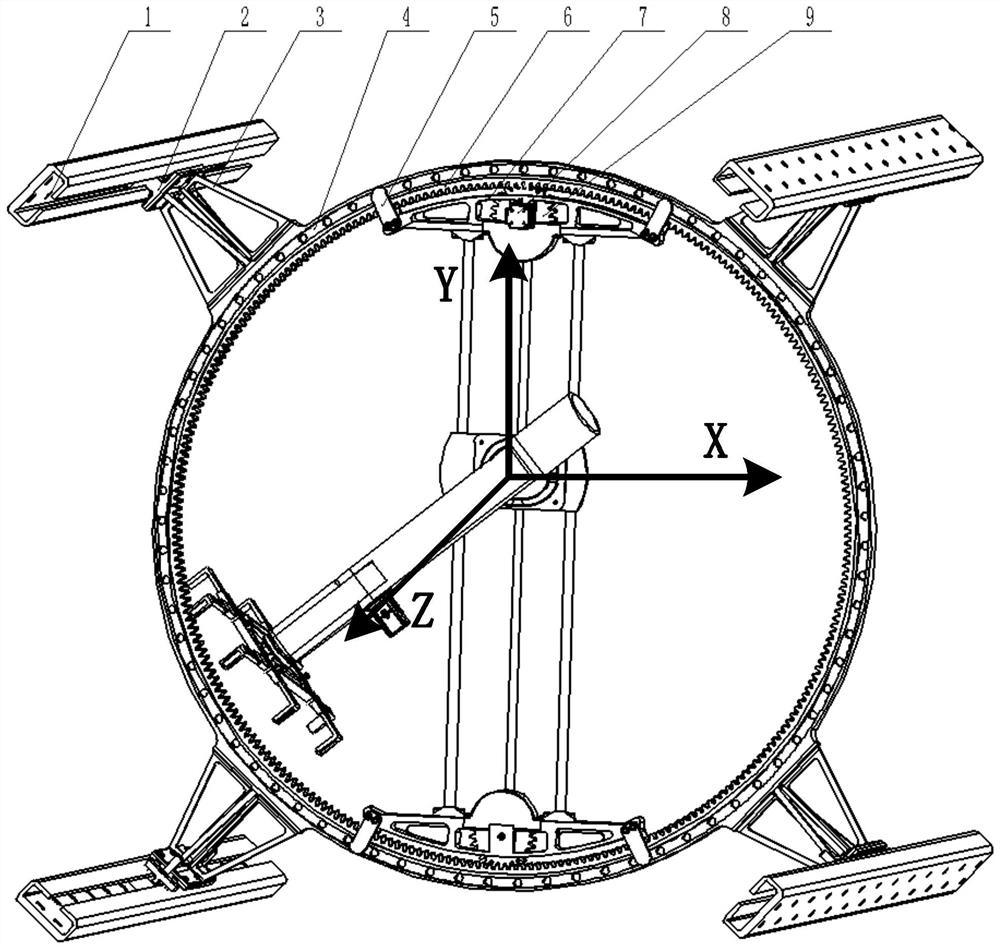

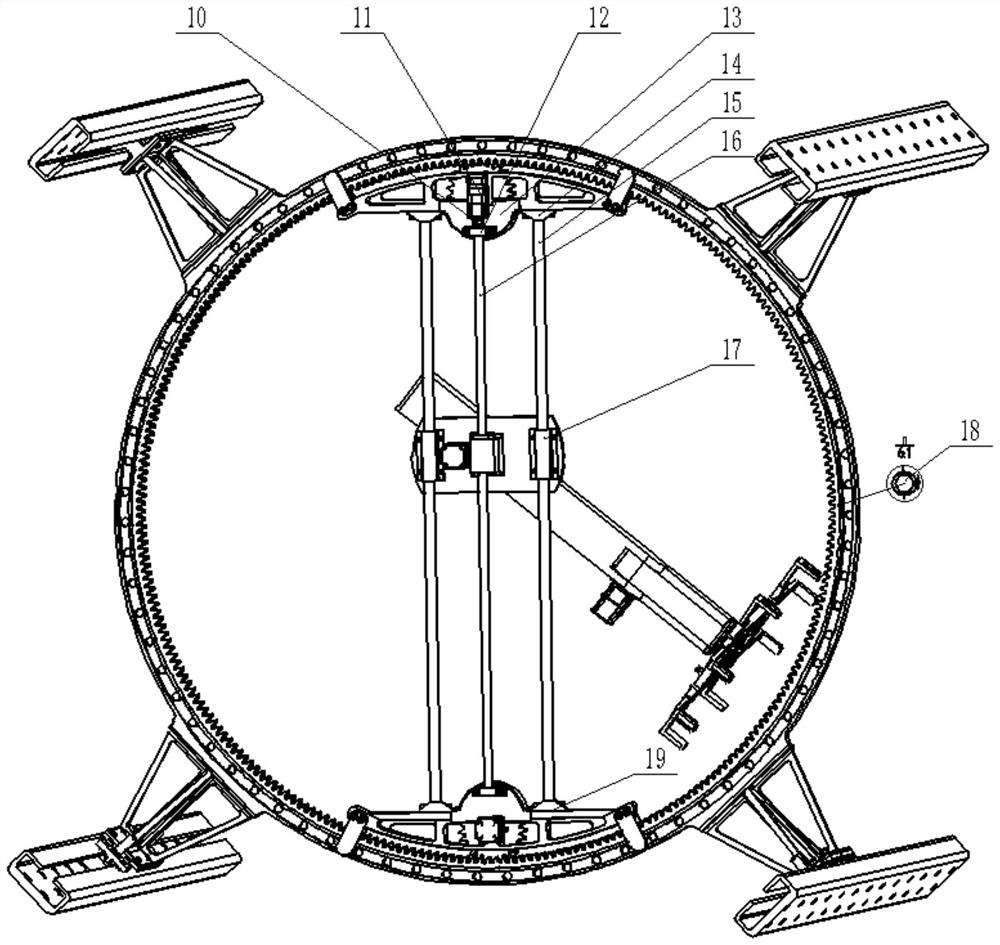

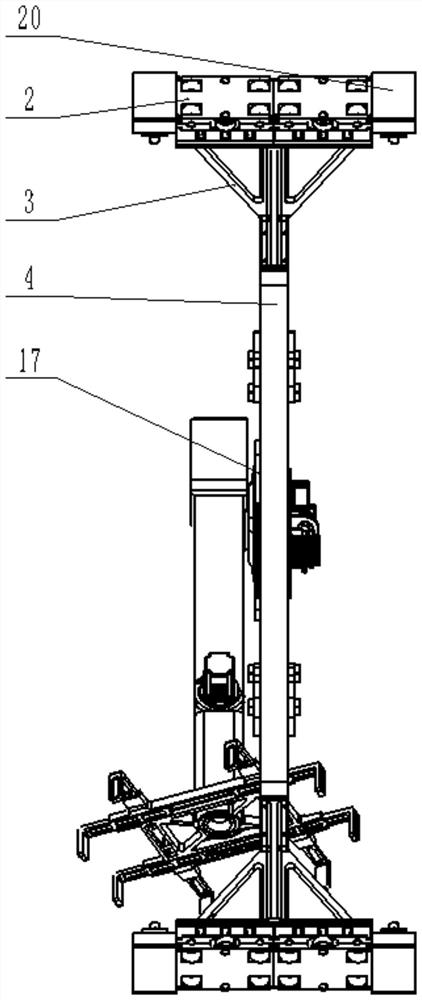

[0025] exist figure 1 , figure 2 and image 3 In the schematic diagram of the six-degree-of-freedom annular tooling and carrying equipment shown, the annular outer bracket 4 and the inner gear ring 6 are fixed through an interference connection, and are fixed in the circumferential direction by a pin shaft 18. The inner bracket 7 of the inner bracket is provided with two pairs of cages 5 which are rotatably connected to the two ends of the inner bracket. The inner bracket is connected with the inner and outer rails on the outer bracket through the rotating rollers set in the cage, so that the inner bracket can be driven by the gear pair. Rotate around the outer bracket; Figure 5 and Figure 6As shown, the middle of the mobile platform 26 is provided with a screw nut support 33, and the two sides of the mobile platform are respectively provided with a self-lubricating bearing support 31, and the self-lubricating bearing 35 is axially fixed on the self-lubricating bearing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com